Spherical zeolite mesoporous composite material and supported catalyst, preparation method and application thereof, and olefin polymerization method

A composite material and supported technology, which is applied in the field of spherical zeolite mesoporous composite materials and supported catalysts and their preparation and application, as well as olefin polymerization, can solve the problem of low catalytic activity and achieve high reaction raw material conversion rate and mesoporous structure stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0058] In the present invention, in step (1), "providing a mesoporous molecular sieve material with a three-dimensional cubic pore structure" can be directly weighing or selecting a product of a mesoporous molecular sieve material with a three-dimensional cubic pore structure, or preparing a product with a three-dimensional cubic pore structure. Mesoporous molecular sieve material with three-dimensional cubic channel structure. The preparation method of the mesoporous molecular sieve material with a three-dimensional cubic channel structure can be implemented according to a conventional method, for example, the preparation method can include: preparing a filter cake of a mesoporous molecular sieve material with a three-dimensional cubic channel structure according to the above method, and then The obtained filter cake is dried, and the templating agent in the product obtained after drying is removed. The conditions for removing the template agent may include: a temperature of ...

Embodiment 1

[0098] This example is used to illustrate the supported metallocene catalyst provided by the present invention and its preparation method.

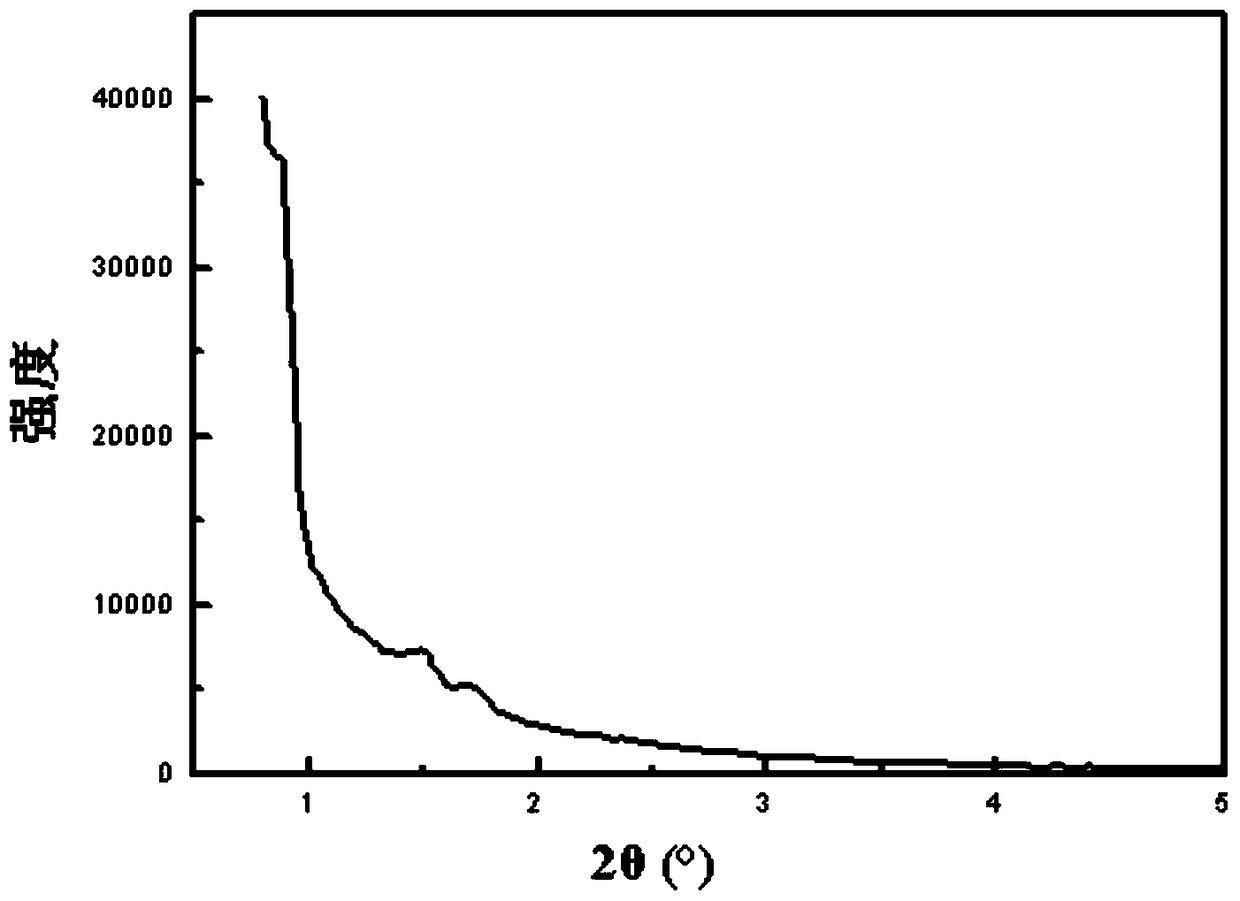

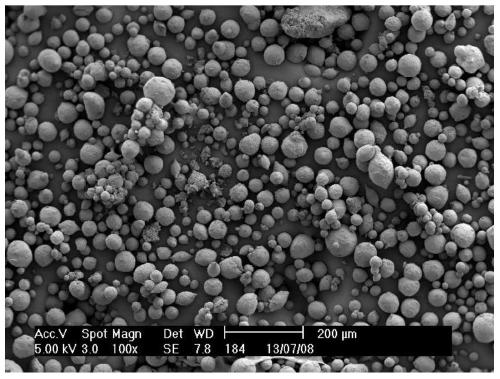

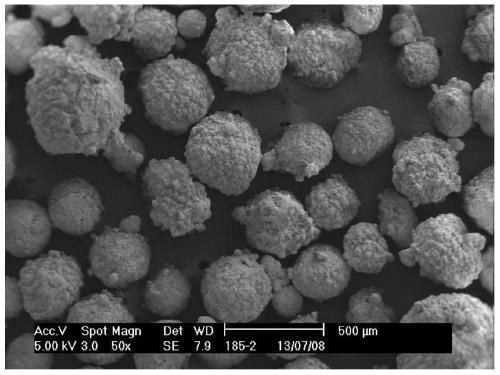

[0099] (1) Preparation of spherical zeolite mesoporous composites

[0100] Add 1.0 g of triblock copolymer polyoxyethylene-polyoxypropylene-polyoxyethylene (Aldrich, P123) and 1.69 g (0.037 mol) of ethanol to 28 mL of a buffer solution of acetic acid and sodium acetate (pH=4.4) , Stir at 15°C until the polyoxyethylene-polyoxypropylene-polyoxyethylene is completely dissolved, then add 6g of trimethylpentane to the above solution, stir at 15°C for 8 hours, then add 2.13g of tetramethoxy Add base silane to the above solution, and after stirring for 20 hours at 15°C, transfer the solution to a polytetrafluoroethylene-lined reaction kettle, crystallize in an oven at 60°C for 24 hours, then filter with suction and wash with distilled water to obtain Filter cake a1 of mesoporous molecular sieve material with three-dimensional cubic pore structu...

experiment Embodiment 1

[0115] This experimental example is used to illustrate the catalytic activity of the supported metallocene catalyst according to the present invention.

[0116] In a 2-liter stainless steel autoclave, replace three times each with nitrogen and ethylene, then add 200 ml of hexane, raise the temperature of the kettle to 80 ° C, then add 800 ml of hexane, and add 2 ml of hexane with the addition of hexane 1 mol / liter of triethylaluminum (TEA, purchased from Zhejiang Furuide Chemical Co., Ltd.) hexane solution, then add 43.3 mg of JKGJZL-BU, feed ethylene to raise the pressure to 1.0MPa and maintain it as 1.0MPa , reacted at 70°C for 1 hour. It is determined by calculation that the efficiency of the catalyst is 1162gPE / gcat . h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com