Polyolefin catalyst and polyolefin and their preparation method

A polyolefin catalyst and catalyst technology are applied in the field of homogeneous catalysis of olefin polymerization and can solve the problems of polluting the environment, low loading rate, and complicated operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] According to the present invention, in step (2), the preparation method of the silica gel is not particularly limited, and may be a conventional method for preparing silica gel in the art. For example, the method includes: contacting water glass with an inorganic acid solution.

[0039] Preferably, the conditions for the contact of the water glass with the inorganic acid include: the temperature can be 10-60°C, preferably 20-40°C; the time can be 1-5 hours, preferably 1.5-3 hours, and the pH value is 2. -4. In order to facilitate the uniform mixing of various substances, the contact of the water glass and the inorganic acid is preferably carried out under stirring conditions.

[0040] According to the present invention, the water glass is a conventional sodium silicate aqueous solution, and its concentration may be 10-50% by weight, preferably 12-30% by weight.

[0041] According to the present invention, the type of the inorganic acid can be conventionally selected in the fi...

Embodiment 1

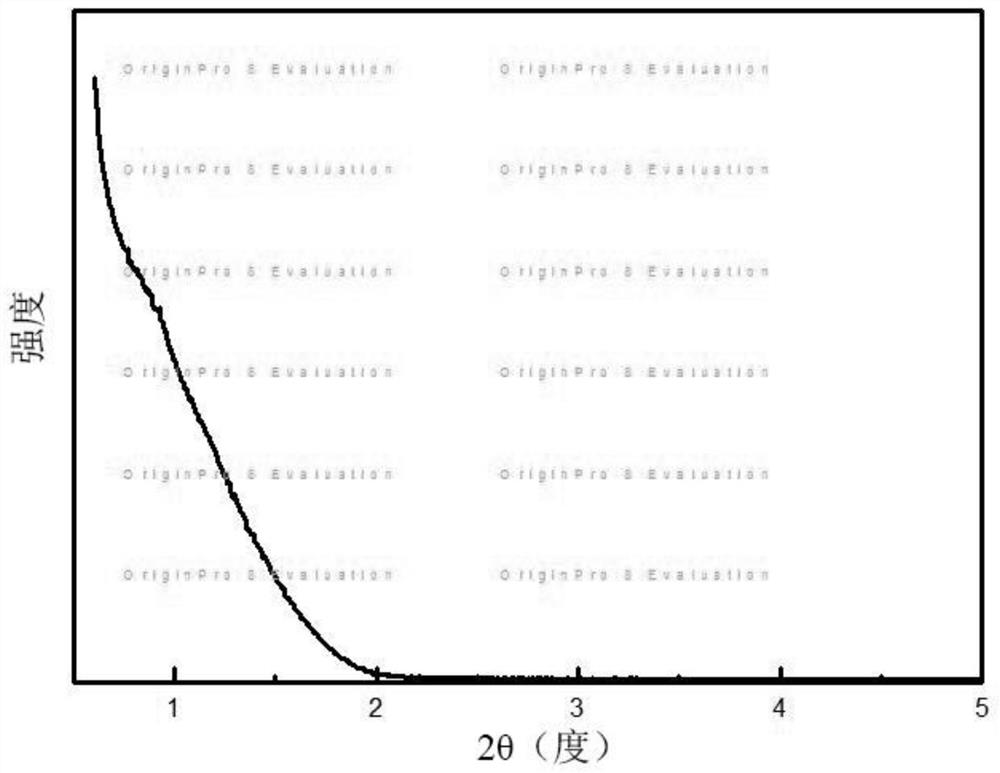

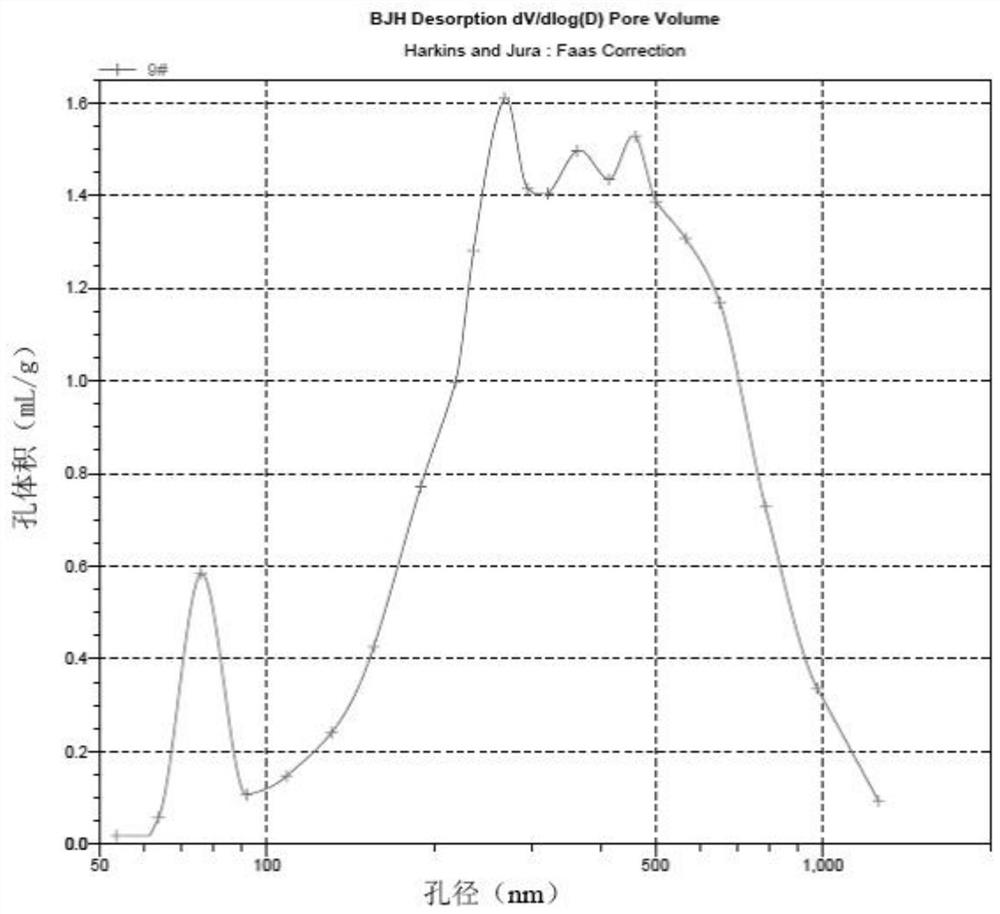

[0077] (1) Preparation of polyolefin catalyst

[0078] At 80°C, cetyltrimethylammonium bromide and ethyl orthosilicate were added to a 25% by weight aqueous ammonia solution, and then deionized water was added. The amount of ethyl orthosilicate added was 1g, the molar ratio of ethyl orthosilicate, cetyltrimethylammonium bromide, ammonia and water in ammonia water is 1:0.37:2.8:142, and stirred at 80°C for 4 hours to obtain two Mesoporous molecular sieve material A1 with hexagonal channel distribution.

[0079] The water glass with a concentration of 15% by weight and a sulfuric acid solution with a concentration of 12% by weight were mixed in a weight ratio of 5:1 and contacted and reacted at 30°C for 1.5h, and then adjusted the pH value to with 98% by weight sulfuric acid 3. Obtain the reaction product silica gel B1.

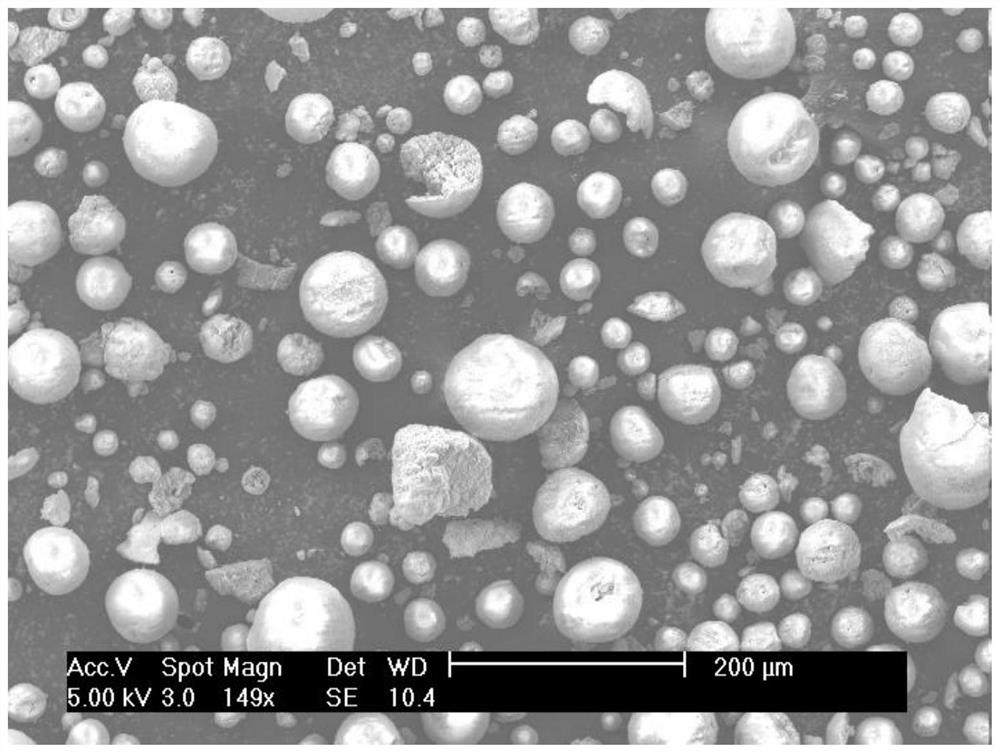

[0080] Stir and mix the 10g mesoporous material A1, 10g silica gel B1, and 10g attapulgite prepared above, pass the mixture into the ceramic membrane filtration sys...

Embodiment 2

[0095] (1) Preparation of polyolefin catalyst

[0096] At 50°C, cetyltrimethylammonium bromide and ethyl orthosilicate were added to a 25% by weight aqueous ammonia solution, and then deionized water was added. The amount of ethyl orthosilicate added was 1g, the molar ratio of ethyl orthosilicate, cetyltrimethylammonium bromide, ammonia and water in ammonia water is 1:0.5:1.5:180, and stirred at 50°C for 7 hours to obtain a Mesoporous molecular sieve material A2 with hexagonal channel distribution.

[0097] The water glass with a concentration of 15% by weight and a sulfuric acid solution with a concentration of 12% by weight were mixed in a weight ratio of 4:1 and contacted for reaction at 40°C for 2 hours, and then adjusted to pH 2 with sulfuric acid with a concentration of 98% by weight , The reaction product silica gel B2 is obtained.

[0098] Stir and mix the 20g mesoporous material A2, 10g silica gel B2 and 8g attapulgite prepared above, pass the mixture into the ceramic memb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com