Spherical composite carrier with macroporous two-dimensional through pore channel and composite material containing polyethylene catalyst, and preparation methods and application thereof

A composite carrier and composite material technology, which are applied to spherical composite carriers with macroporous two-dimensional straight channels and composite materials containing polyethylene catalysts, as well as their preparation and application fields, can solve the problem of poor thermal stability and hydrothermal stability, affecting load effect, pore wall collapse and other problems, to achieve the effect of regular and orderly pore structure, good sphere flow performance, and stable mesoporous structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] In a second aspect, the present invention provides a method for preparing a spherical composite carrier with large pores and two-dimensional straight-through channels, the method comprising the following steps:

[0040] Preparation of mesoporous material: in the presence of an alkaline solution, the template agent and the silicon source are mixed and reacted, and the mixture obtained after the mixed reaction is filtered;

[0041] Prepare silica gel: in the presence of inorganic acid solution, react water glass and n-butanol, and then adjust the pH value of the solution obtained after the reaction to 2-4;

[0042] Preparing the carrier: mixing the prepared mesoporous material and the silica gel, followed by grinding, spray drying and calcining;

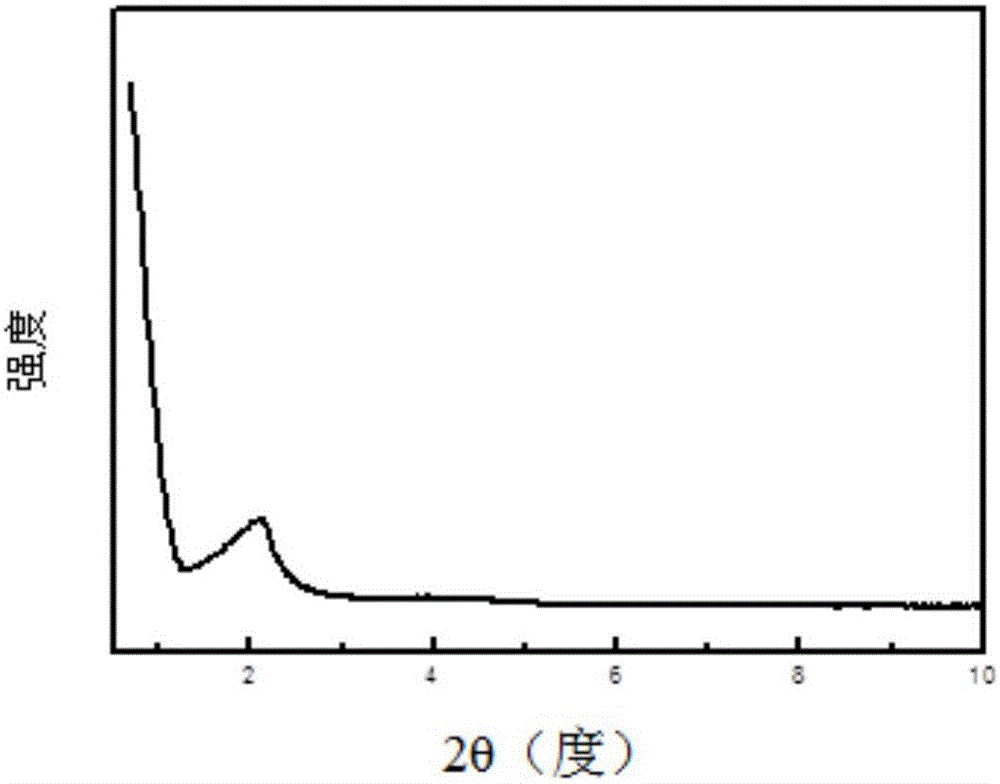

[0043] Wherein, the method makes the obtained carrier have an average particle diameter of 10-80 μm and a specific surface area of 200-600 μm 2 / g, the pore volume is 0.1-2.5mL / g, the pore size distribution is a bimodal distr...

Embodiment 1

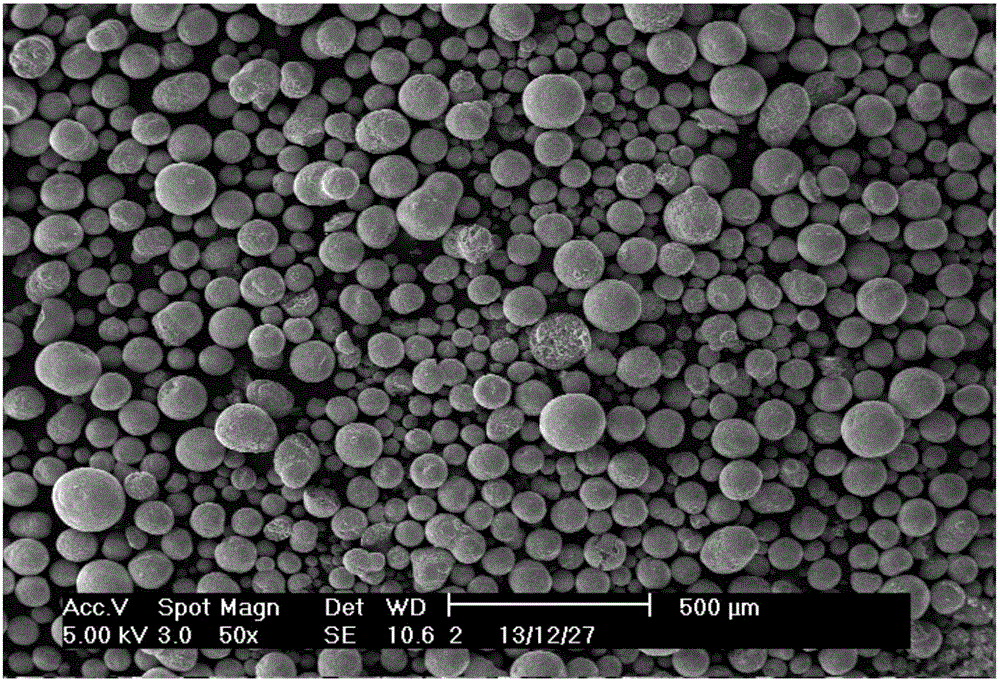

[0094] This example is used to illustrate the macroporous two-dimensional through-channel spherical composite carrier, the composite material containing polyethylene catalyst and their preparation methods.

[0095] (1) Preparation of carrier

[0096] 0.1mol tetraethyl orthosilicate and 0.037mol cetyltrimethylammonium bromide were added to 25% by weight of ammonia solution, mixed reaction was carried out at 80°C and pH value was 9 for 4h, and then the mixed The mixture obtained after the reaction is filtered and washed, and finally the obtained reaction material is subjected to suction filtration to form a filter cake.

[0097] Concentration is 15% by weight of water glass and concentration of 12% by weight of sulfuric acid solution and n-butanol mixed with a weight ratio of 5:1:1 and contact reaction at 20 ° C for 1.5h, followed by concentration of 98% by weight Sulfuric acid was used to adjust the pH value to 3, and then the obtained reaction material was subjected to suctio...

Embodiment 2

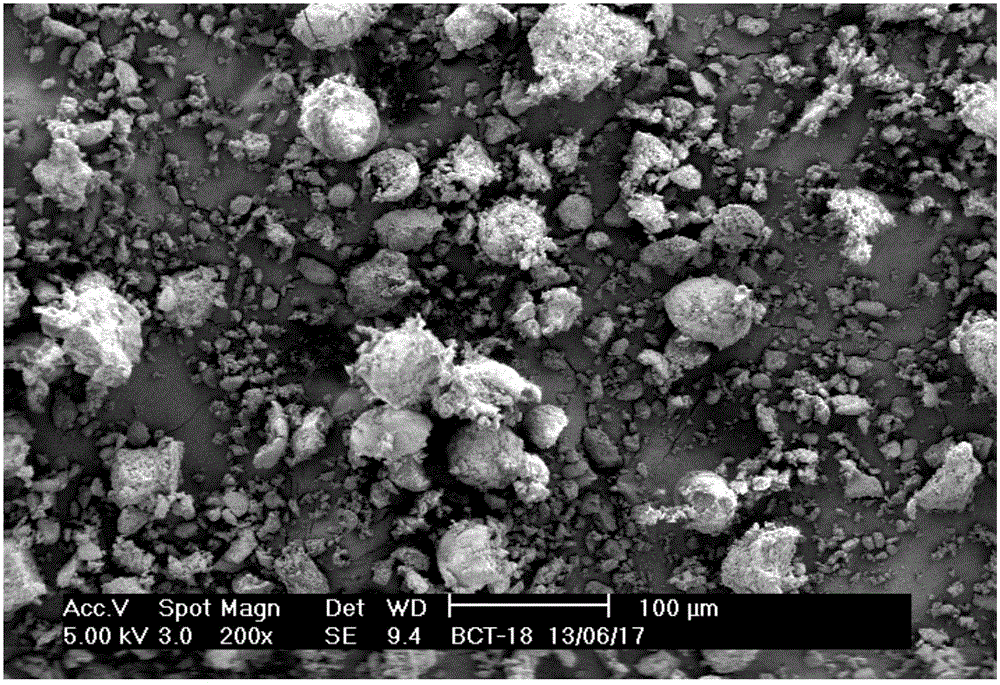

[0116] This example is used to illustrate the macroporous two-dimensional through-channel spherical composite carrier, the composite material containing polyethylene catalyst and their preparation methods described in the present invention.

[0117] (1) Preparation of carrier

[0118] 0.1mol ethyl orthosilicate and 0.032mol cetyltrimethylammonium bromide are added in the ammonia solution of 22% by weight, carry out mixing reaction under the condition of 75 ℃ and pH value 9.5, then mix reaction The obtained mixture is filtered and washed, and finally the obtained reaction material is subjected to suction filtration to form a filter cake.

[0119] The concentration is 13% by weight of water glass and the concentration of 15% by weight of nitric acid solution and n-butanol are mixed with a weight ratio of 4:1.2:1 and contacted at 25 ° C for 1.3h, followed by a concentration of 98% by weight Sulfuric acid was used to adjust the pH value to 3.5, and then the obtained reaction mate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com