Straw deep-burying wedge type hollow plough

A straw and hollow technology, which is applied in the field of straw deep burial returning equipment, can solve the problems of limited adaptability and achieve the effect of less operation links, high reliability, and large dosage of straw returning to the field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

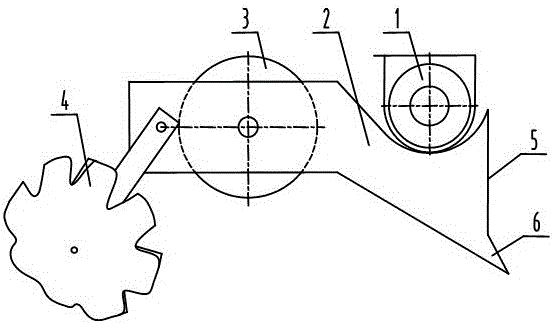

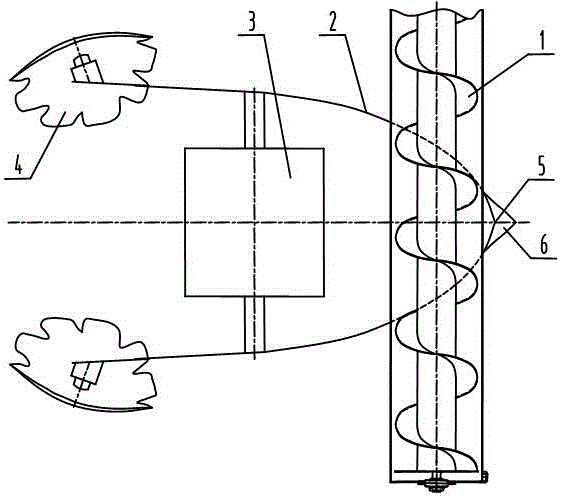

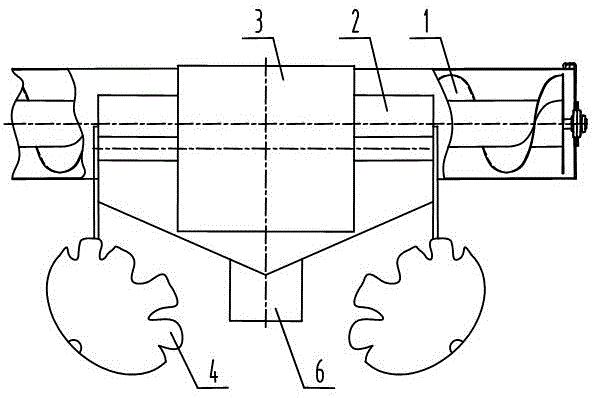

[0013] Such as figure 1 , figure 2 , image 3 As shown, a schematic diagram of the structure of the wedge-type hollow plow for deep-layer accumulation of straw of the present invention is given, including a straw conveying auger 1, a wedge-shaped hollow plow body 2, a straw pressing wheel 3, a soil-covering disc 4, and a soil-breaking blade 5. The wedge-shaped hollow plow body 2 is that the thin-walled plates on both sides are connected and intersected forward in a streamline arc to form a vertical soil-breaking blade 5. The thin-walled plates on both sides form a cavity shape, and the rear ends of the thin-walled plates on both sides form an outer The opening is opened, and the straw pressing wheel 3 is arranged to rotate horizontally between the thin-walled plates on both sides. arc, the straw conveying auger 1 is disposed in the concave a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com