Anti-oxidant magnetic heating film for non-magnetizer cooker and preparation thereof

An anti-oxidation and heating film technology, applied in special materials for cooking utensils, etc., can solve the problems of easy loosening, short service life, and large gap between thermal expansion and contraction between magnetic products and ceramics, and achieves extended service life, reduced costs, The effect of improving the magnetic heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

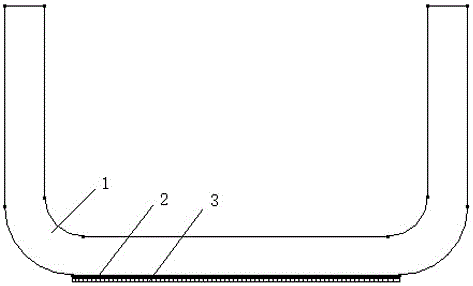

Image

Examples

Embodiment 1

[0025] A method for preparing an anti-oxidation magnetic heating film for non-magnetic pots and utensils, mainly comprising the following steps:

[0026] 1) material preparation

[0027] A. Weigh the raw materials of the magnetic heating layer according to the following weight percentages: 50% of 430 stainless steel powder, 25% of nickel powder, 5% of copper powder, 15% of glass powder, and 5% of aluminum powder; after adding the raw materials into varnish according to the ink preparation process Stir and mix evenly and use precision roller equipment for high-speed grinding to fully refine the magnetic heating layer slurry, which is sealed for later use.

[0028] B. Weigh high thermal conductivity glass raw materials according to the following volume percentage: ZnO 30%, B 2 o 3 10%, P 2 o 5 30%, Bi 2 o 3 10%, Al 2 o 3 15%, Fe 2 o 3 5%; the raw materials are mixed according to the ordinary glass powder preparation process → melting → ball milling → sieving to prepar...

Embodiment 2

[0035] A method for preparing an anti-oxidation magnetic heating film for non-magnetic pots and utensils, mainly comprising the following steps:

[0036] 1) material preparation

[0037] A. Weigh the raw materials of the magnetic heating layer according to the following weight percentages: 55% of 430 stainless steel powder, 30% of nickel powder, 8% of copper powder, 5% of glass powder, and 2% of aluminum powder; add the raw materials to the varnish according to the ink preparation process Stir and mix evenly and use precision roller equipment for high-speed grinding to fully refine the magnetic heating layer slurry, which is sealed for later use.

[0038] B. Weigh high thermal conductivity glass raw materials according to the following volume percentage: ZnO 40%, B 2 o 3 30%, P 2 o 5 10%, Bi 2 o 3 12%, Al 2 o 3 5%, Fe 2 o 3 3%; the raw materials are mixed according to the ordinary glass powder preparation process → melting → ball milling → sieving to prepare glas...

Embodiment 3

[0045] A method for preparing an anti-oxidation magnetic heating film for non-magnetic pots and utensils, mainly comprising the following steps:

[0046] 1) material preparation

[0047] A. Weigh the raw materials of the magnetic heating layer according to the following weight percentages: 70% of 430 stainless steel powder, 10% of nickel powder, 10% of copper powder, 8% of glass powder, and 2% of aluminum powder; after adding the raw materials into varnish according to the ink preparation process Stir and mix evenly and use precision roller equipment for high-speed grinding to fully refine the magnetic heating layer slurry, which is sealed for later use.

[0048] B. Weigh high thermal conductivity glass raw materials according to the following volume percentage: ZnO 50%, B 2 o 3 10%, P 2 o 5 10%, Bi 2 o 3 20%, Al 2 o 3 10%, Fe 2 o 3 0%; The raw materials are mixed according to the ordinary glass powder preparation process → melting → ball milling → sieving to pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com