Lathe dedusting device

A technology of a dust removal device and a lathe, which is applied in the field of lathes, can solve the problems of reducing production efficiency, error of processing results, etc., and achieves the effects of simple structure, good dust removal effect, and easy use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

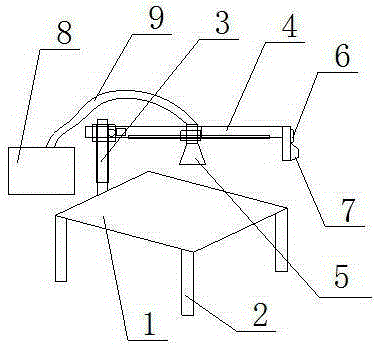

[0016] Combine figure 1 The illustrated dust removal device for a lathe includes a lathe 1 and a dust collector. A leg 2 is provided under the lathe 1, and the lathe 1 is fixed on the leg 2. The dust collector includes a bracket and a vacuum cleaner, and the bracket includes a bracket fixed on one side of the lathe The vertical column 3 and the supporting beam 4 set on the column 3, the suction nozzle 5 of the vacuum cleaner is set on the beam 4, the end of the beam 4 away from the column 3 is provided with a controller 6 and a handle 7, and the vacuum cleaner is controlled by 器6 Control.

[0017] In this embodiment, the body 8 of the vacuum cleaner is arranged around the lathe 1, and a dust suction pipe 9 is arranged between the body 8 and the dust suction nozzle 5.

[0018] In this embodiment, the column 3 is vertically arranged, and a lifting rack is arranged vertically on the column 3, and a lifting gear connected with the lifting rack is provided at the connection of the beam 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com