Partial pendulum and steering mechanism for partial pendulum form vehicle

A steering mechanism and yaw-type technology, which is applied in the direction of motor vehicles, bicycles, transportation and packaging, etc., can solve the problems of large installation errors, excessive vehicle size, and increased number of parts, so as to ensure the movement space and increase the installation space , the effect of increasing the range of motion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

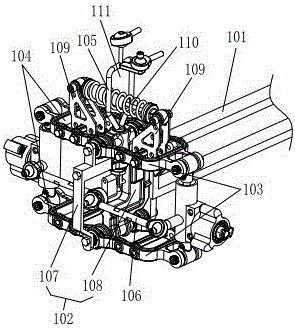

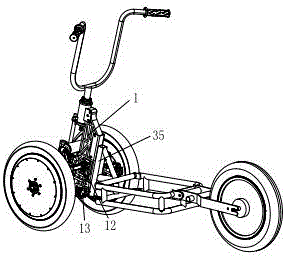

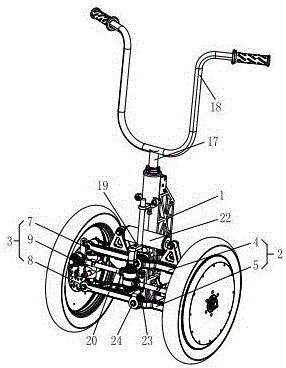

[0038] see Figure 2 to Figure 12 , the present invention provides a yaw and steering mechanism on a yaw type vehicle, comprising a main frame 1, a left rocker assembly 2 and a right rocker assembly 3 symmetrically arranged on both sides of the main frame 1, the The left rocker arm assembly 2 includes a left upper rocker arm 4, a left lower rocker arm 5 and a left steering knuckle structure 6; the right rocker arm assembly 3 includes a right upper rocker arm 7, a right lower rocker arm 8 and a right steering knuckle structure 9. The vehicle frame 1 includes a front bracket 10, a main beam 11, a first rear bracket 12 and a second rear bracket 13. The top of the main beam 11 has a top extension section 14, and the front steering column sleeve 15 is arranged on the top extension section 14. The axis of the front steering column sleeve 15 is collinear with the axis of the bearing groove 16 arranged on the main beam 11, the semi-open front steering column 17 passes through the fron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com