Control method for ethylene carbonate synthesis process

A technology of ethylene carbonate synthesis process, which is applied in the field of control of ethylene carbonate synthesis process, can solve the problems of reactor overheating, circulation reduction, bed overheating, etc., and achieve good technical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

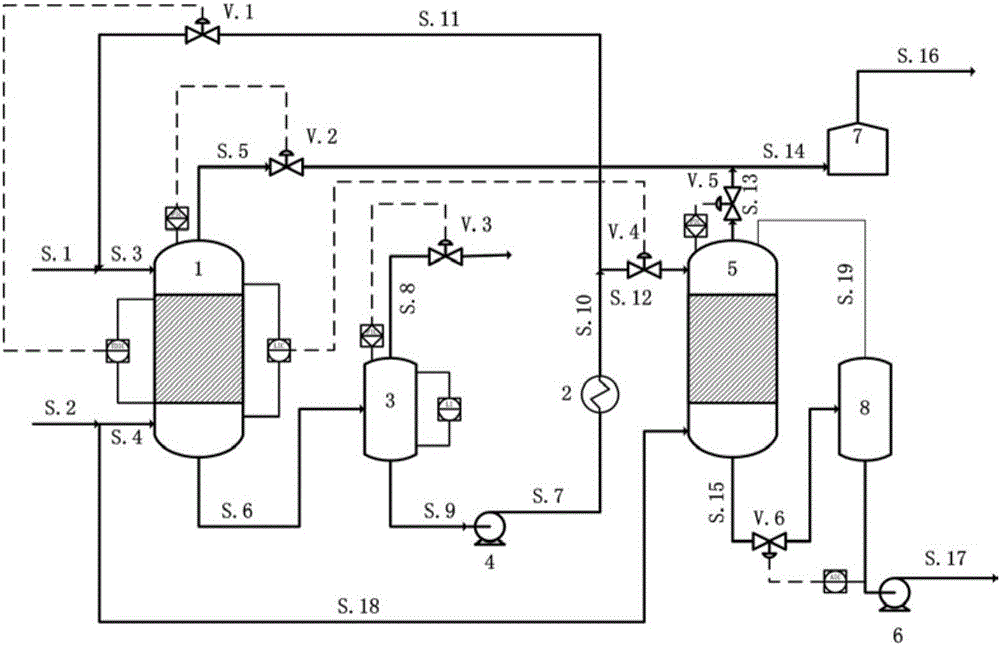

[0043] Combine below figure 1 Example 1 will be described.

[0044] process such as figure 1 Shown, ethylene oxide feed (S.1) flow rate is 100kg / h, enters the top of one section synthesis reactor (1), carbon dioxide feed (S.2) flow rate is 100kg / h, and 95% wherein enters The lower part of the first-stage synthesis reactor (3), the reactor pressure is controlled at 2.5MPa by the gas phase pipeline pressure control valve, the liquid level in the reactor is controlled by the first-stage to the second-stage liquid phase production flow control valve, and the temperature rise in the reactor is controlled by the circulation The material flow control valve is controlled at about 20°C. The reactor inlet temperature was 80°C. When the system is stable, the temperature of the liquid stream (S.6) obtained at the bottom of the first section of synthesis reactor is about 100°C, and enters the buffer tank (3) of the circulation pump. The liquid level in the buffer tank is indirectly cont...

Embodiment 2

[0049] Combine below figure 1 Example 2 will be described.

[0050] process such as figure 1 Shown, oxirane feeding (S.1) flow rate is 100kg / h, enters the top of one section synthesis reactor (1), and carbon dioxide feeding (S.2) flow rate is 100kg / h, and 80% wherein enters The lower part of the first-stage synthesis reactor (3), the reactor pressure is controlled at 1.5MPa by the gas phase pipeline pressure control valve, the liquid level in the reactor is controlled by the first-stage to the second-stage liquid phase production flow control valve, and the lower layer of the catalyst bed in the reactor The temperature was controlled at about 100°C by a recycle material flow control valve. The reactor inlet temperature was 80°C. When the system is stable, the temperature of the liquid stream (S.6) obtained at the bottom of the first section of synthesis reactor is about 100°C, and enters the buffer tank (3) of the circulation pump. The liquid level in the buffer tank is ind...

Embodiment 3

[0055] Combine below figure 1 Example 3 will be described.

[0056] process such as figure 1 Shown, oxirane feeding (S.1) flow rate is 100kg / h, enters the top of one section synthesis reactor (1), and carbon dioxide feeding (S.2) flow rate is 100kg / h, and 70% wherein enters The lower part of the first-stage synthesis reactor (3), the reactor pressure is controlled at 3.0MPa by the gas phase pipeline pressure control valve, the liquid level in the reactor is controlled by the first-stage to the second-stage liquid phase production flow control valve, and the temperature rise in the reactor is controlled by the circulation The material flow control valve is controlled at about 15°C. The reactor inlet temperature was 90°C. When the system is stable, the temperature of the liquid stream (S.6) obtained at the bottom of the first section of the synthesis reactor is about 105°C, and enters the buffer tank (3) of the circulating pump. The liquid level in the buffer tank is controll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com