Method and device for continuous production of natural perfume by immobilized hydroperoxide lyase

A technology of hydroperoxide and vegetable hydroperoxide, applied in biochemical equipment and methods, biochemical cleaning equipment, enzymology/microbiology equipment, etc., can solve problems such as complexity, low product yield, and instability , to achieve the effect of reducing the amount of enzyme required, simple operation, and increasing the output per unit volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

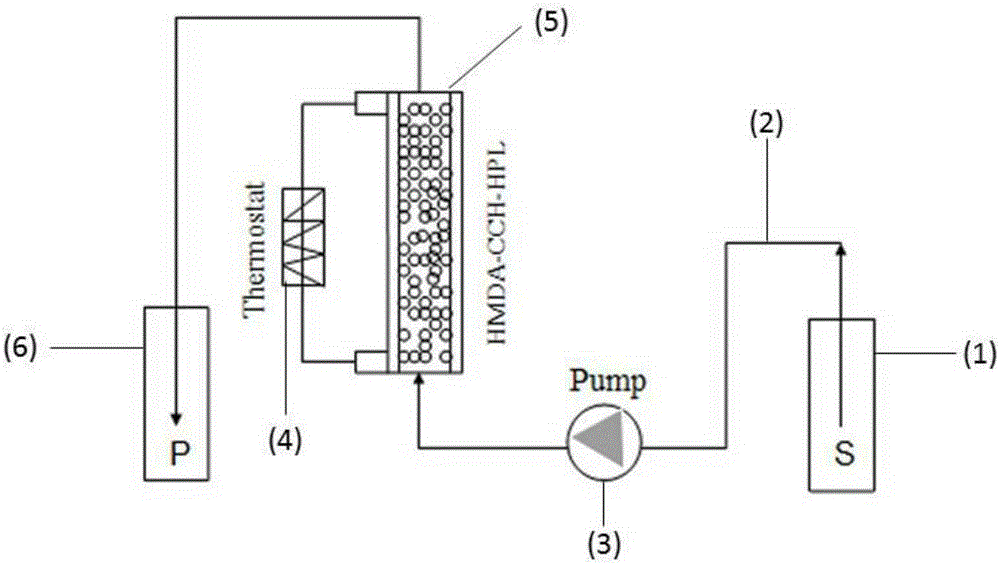

Method used

Image

Examples

preparation example Construction

[0042] The preparation method of fatty acid hydroperoxide of the present invention is: prepare fatty acid hydroperoxide (HPOs) through LOX reaction. 0.1M free linoleic acid was dispersed in borate buffer (0.2M) at pH 9.0, stirred evenly at 4°C in a fermenter, added LOX, passed oxygen and pressurized to 0.3MPa for reaction. After 1.5h, the reaction was terminated and a certain amount of product was diluted with ethanol to measure its UV absorbance at 234nm, and then the concentration of HPOs in the reaction solution was calculated according to the molar absorptivity (ε=25000cm-1M-1). Finally, the reaction product solution was refrigerated at 4°C until use.

[0043] The extraction method of amaranth hydroperoxide lyase of the present invention is: after removing root and stem, fresh amaranth leaves are chopped and mixed with Tris-HCl buffer solution (0.1M and containing 0.5% (m / v) PVPK- 30) Mix according to the ratio of 1:3, homogenize for 1min (10s×6). After four layers of ga...

Embodiment 1

[0048] Preparation of chitosan composite hydrogel: 2.5g chitosan and 2.5g gamma-carrageenan were added to 100g acetic acid solution containing 5% v / v and stirred until completely dissolved to obtain a mixed solution. Then 50 ml of the mixed solution was added dropwise into 500 ml of 0.5 M NaOH solution using a syringe and stirred slowly (50 rpm) for 1 day to form hydrogel microspheres with a diameter of 1–2 mm. Excess glutaraldehyde was used to activate the amino groups on the surface of the hydrogel microspheres to introduce aldehyde groups, and then 7.75 mmol of 1,6-hexanediamine was added. Linked on the surface of chitosan composite hydrogel microspheres.

[0049] Immobilization of hydroperoxide lyase: 15.5mmol of chitosan composite hydrogel microspheres with 1,6-hexamethylenediamine (HMDA) attached to the surface were immersed in 300ml of an aqueous solution containing 155mmol of EDC, and then 100ml of 15.5 The PBS solution of mmol HPL was then shaken at 4°C for 30 minute...

Embodiment 2

[0055] Preparation of chitosan composite hydrogel: 7.5g chitosan and 7.5g gamma-carrageenan were added to 100g acetic acid solution containing 25% v / v and stirred until completely dissolved to obtain a mixed solution. Then 50 ml of the mixed solution was added dropwise into 250 ml of 2.5 M NaOH solution using a syringe and stirred slowly (10 rpm) for 5 days to form hydrogel microspheres with a diameter of 1–2 mm. Excess glutaraldehyde was used to activate the amino groups on the surface of the hydrogel microspheres to introduce aldehyde groups, and then 46.56 mmol of 1,6-hexanediamine was added. Linked on the surface of chitosan composite hydrogel microspheres.

[0056] The immobilization of hydroperoxide lyase: the chitosan composite hydrogel microsphere that 46.56mmol surface is connected with 1,6-hexamethylenediamine (HMDA) is immersed in the aqueous solution that contains 46.56mmol EDC in 300ml, then adds 100ml containing The PBS solution of 46.56mmol HPL was then shaken ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com