Lithium titanate flexible self-supporting composite electrode and preparation method thereof

A composite electrode, self-supporting technology, applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problems that are difficult to apply to flexible lithium-ion batteries, achieve good rate performance and cycle stability, high flexibility, good conductivity and mechanical intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

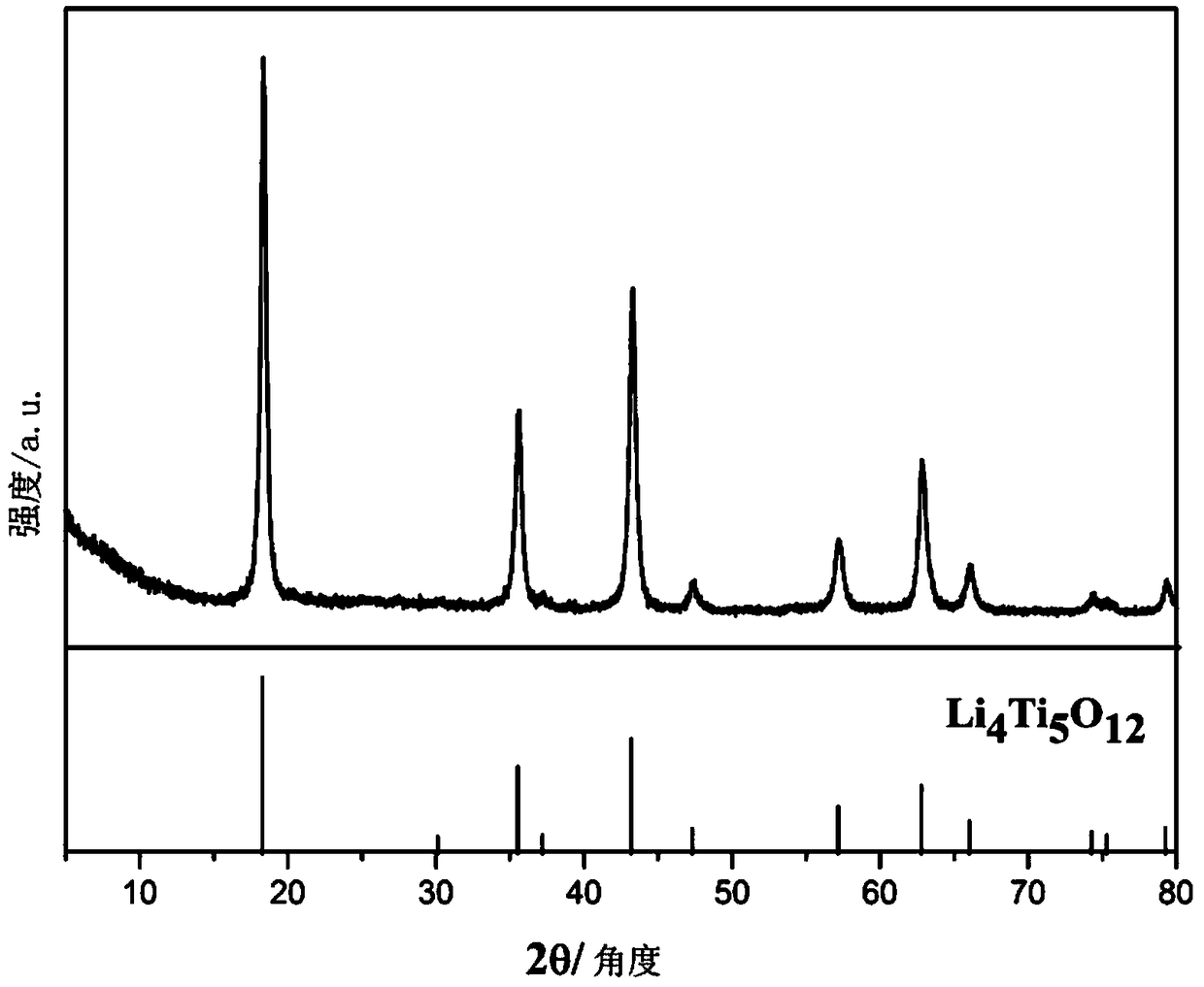

[0025] Another aspect of the embodiments of the present invention provides a method for preparing a lithium titanate flexible self-supporting composite electrode, comprising the following steps:

[0026] S01. Provide an inorganic titanium source, a lithium source, a solution containing hydroxide ions and hydrogen peroxide, and mix and process to prepare a lithium-containing titanium peroxide complex solution;

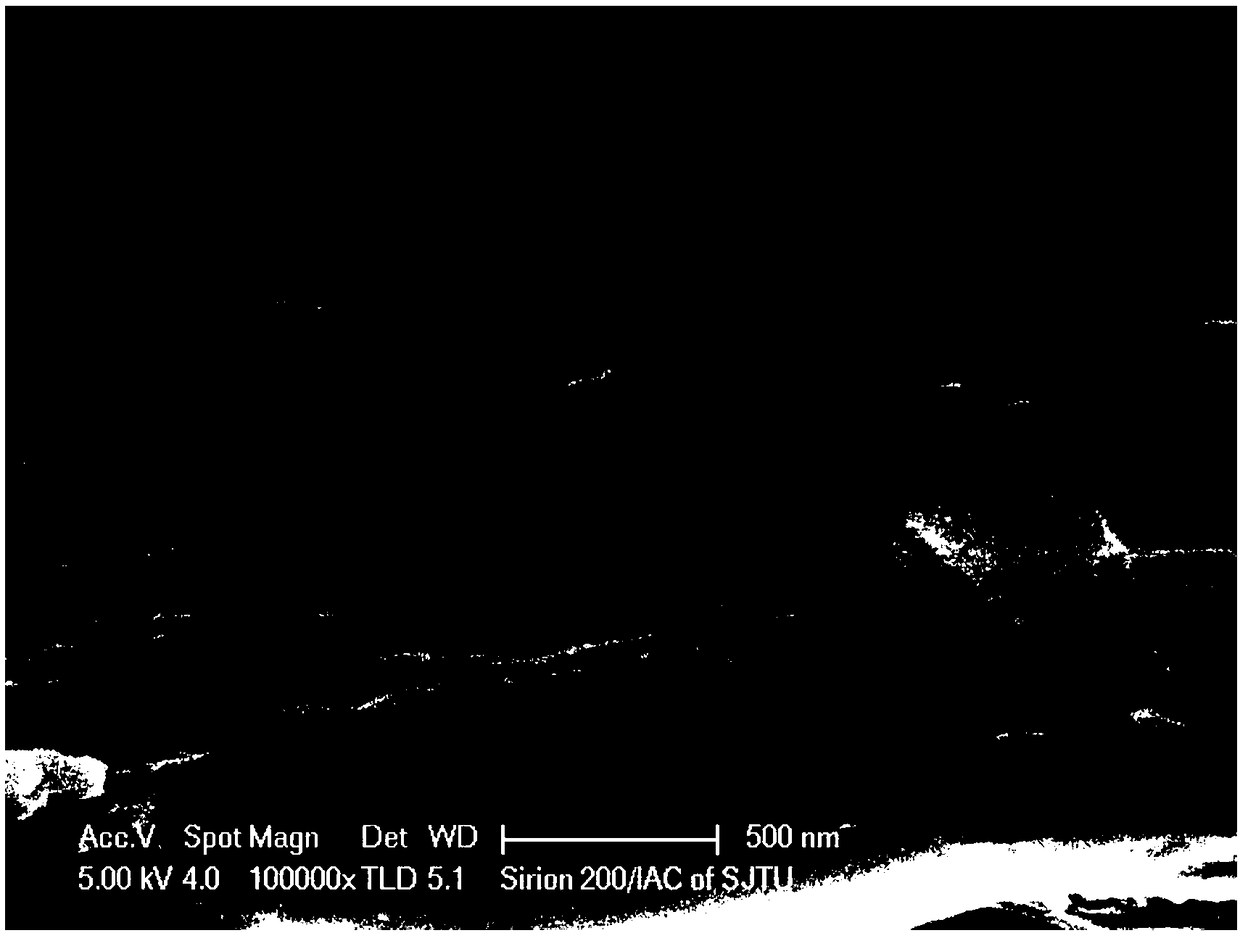

[0027] S02. Adding a hydrophilic carbon material into the lithium-containing titanium peroxide complex solution, and directly forming or forming a self-supporting precursor material after hydrothermal reaction;

[0028] S03. After the self-supporting precursor material is dried, it is calcined in a reducing atmosphere to prepare a lithium titanate flexible self-supporting composite electrode.

[0029] The preparation method of the lithium titanate flexible self-supporting composite electrode provided in the embodiment of the present invention uses the inorganic titanium...

Embodiment approach

[0041] As a preferred embodiment, the hydrophilic carbon material is graphene oxide or hydrophilic carbon nanotubes, and the step of preparing the self-supporting precursor material using graphene oxide or hydrophilic carbon nanotubes includes: The lithium-containing titanium peroxide complex solution is added to the graphene oxide or hydrophilic carbon nanotubes, and after dispersion treatment, hydrothermal reaction is carried out.

[0042] As another preferred embodiment, the hydrophilic carbon material is hydrophilic carbon cloth, and the step of preparing the self-supporting precursor material by using hydrophilic carbon cloth includes: adding lithium-containing titanium peroxide complex The solution is added to the hydrophilic carbon cloth for hydrothermal reaction to directly prepare a self-supporting precursor material.

[0043] Further, after the hydrothermal reaction, further treatment is carried out in combination with the type of hydrophilic carbon material.

[004...

Embodiment 1

[0051] A preparation method of lithium titanate flexible self-supporting composite electrode, comprising the following steps:

[0052] (1) Mix commercial P25 as a titanium source with a concentration of 0.43M lithium hydroxide (LiOH) solution, control the value of Li / Ti to 4.3:1, transfer to a temperature-controllable stirrer coupled with an ultrasonic generator, Sonicate for 10 minutes.

[0053] (2) adding concentration in the stirrer described in step (1) is 30wt% hydrogen peroxide (H 2 o 2 ), the addition amount is 1.1ml per 10ml of lithium hydroxide (LiOH) solution, heat the stirrer to 25°C, and stir for 24 hours to dissolve the solid to form a titanium peroxide complex solution.

[0054] (3) Add graphene oxide in the complex solution described in step (2), the addition is 0.35g / 1g Ti 4+ , after ultrasonic dispersion for 10 minutes, transfer to a reaction vessel with stirring function, and react at 150° C. for 6 hours with the stirring function turned off.

[0055] (4)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Discharge capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com