Ferronickel/carbon film-nickel integrated composite electrode and preparation method thereof

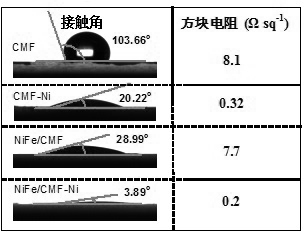

A composite electrode, carbon film technology, applied in electrodes, battery electrodes, circuits, etc., can solve the problems of unfavorable growth of metal catalyst particles, low hydrophilicity, etc., to improve hydrophilicity and electrical conductivity, improve electrochemical performance and Stability and good hydrophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

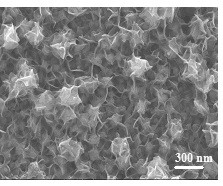

[0022] (1) Prepared by vapor deposition method with a certain thickness (0.5 μm) and area (4 cm -2 ) of the carbon film.

[0023] (2) Electrodeposition is used to deposit nickel-iron bimetal on one side of the carbon film. Preparation of electrodeposition solution: 2.1 g L -1 Nickel sulfate, 2.2 g L -1 Ferric sulfate, 3.3 g L -1 Ammonium sulfate, use 0.5 mol L -1 Sulfuric acid adjusted the pH of the solution to 4. Electrodeposition was performed in a three-electrode system on an electrochemical workstation. The platinum sheet electrode was used as the counter electrode, the saturated calomel electrode was used as the reference electrode, and the carbon film was used as the working electrode. The electrodeposition voltage was -1.7 V, and the electrodeposition time was 400 s. The composite film is taken out and dried to obtain a nickel-iron / carbon film integrated composite electrode (NiFe / CMF). (this material is used as a comparison sample)

Embodiment 2

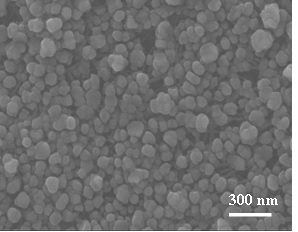

[0025] (1) Prepared by vapor deposition method with a certain thickness (0.5 μm) and area (3 cm -2 ) of the carbon film.

[0026] (2) Metal nickel is electrodeposited on one side of the carbon film by electroplating. Preparation of electroplating solution: 270 g L -1 Nickel sulfate, 50 g L -1 Sulfuric acid, 70 g L -1 Nickel chloride, 2 g L -1 C 12 h 25 NaO 4 S. The contact area between the carbon film and the electrolyte is 0.2 mAcm -2 . The negative electrode of the power supply is connected to the carbon film, the positive electrode is connected to the nickel plate, the voltage is 3 V, and the current is 2 A dm -2 , the plating time is 10 s. Take out the carbon film-nickel composite film and dry it. (3) Electrodeposition is used to deposit nickel-iron bimetal on the other side of the carbon film-nickel composite film. Preparation of electrodeposition solution: 2.1 g L -1 Nickel sulfate, 2.2 g L -1 Ferric sulfate, 3.3 g L -1 Ammonium sulfate, use 0.5 mo...

Embodiment 3

[0028] (1) Prepared by vapor deposition method with a certain thickness (0.2 μm) and area (2 cm -2 ) of the carbon film.

[0029] (2) Metal nickel is electrodeposited on one side of the carbon film by electroplating. Preparation of electroplating solution: 270 g L -1 Nickel sulfate, 50 g L -1 Sulfuric acid, 70 g L -1 Nickel chloride, 2 g L -1 C 12 h 25 NaO 4 S. The contact area between the carbon film and the electrolyte is 0.2 mAcm -2 . The negative electrode of the power supply is connected to the carbon film, the positive electrode is connected to the nickel plate, the voltage is 3 V, and the current is 2 A dm -2 , the plating time is 20 s. Take out the carbon film-nickel composite film and dry it. (3) Electrodeposition is used to deposit nickel-iron bimetal on the other side of the carbon film-nickel composite film. Preparation of electrodeposition solution: 2.1 g L -1 Nickel sulfate, 2.2 g L -1 Ferric sulfate, 3.3 g L -1 Ammonium sulfate, use 0.5 mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com