Flexible integrated carbon-coated tungsten oxide/carbon nanotube film composite electrode and its preparation method

A carbon nanotube film and composite electrode technology, applied in electrode manufacturing, electrode rolling/calendering, hybrid capacitor electrodes, etc. Binder-free, good conductive network effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

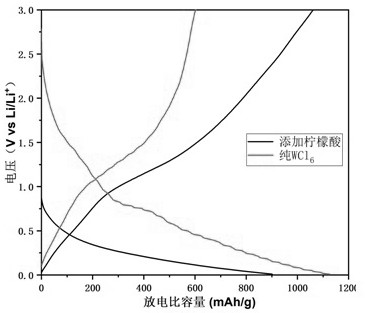

[0022] Dissolve 1 g of tungsten hexachloride in 50 mL of a mixed solution (25 mL of absolute ethanol and 25 mL of deionized water), ultrasonically disperse it, and place it in a spray pot. In the preparation of carbon nanotube film (10*30 cm 2 ) while spraying the mixed solution evenly on the surface of the carbon nanotube bundles. The sprayed composite film is left to stand, air-dried, and cut. The cut composite film was placed in a high-pressure reactor for solvothermal reaction. The solvent in the reaction kettle was a mixed solution of absolute ethanol and water, with a volume ratio of 1:1 (60 mL water: 60 mL absolute ethanol); the reaction temperature was 180 °C, and the reaction time was 4 h. Cool naturally after the reaction, take out the composite film, and dry naturally. Put the dried composite film in a high-temperature reaction furnace, under a nitrogen atmosphere, calcine at a temperature of 500 °C, and hold for 1 h. After cooling, an integrated carbon-coated tu...

Embodiment 2

[0024] Dissolve 1g of tungsten hexachloride and 1g of citric acid in 50 mL of mixed solution (25 mL of absolute ethanol and 25 mL of deionized water), ultrasonically disperse, and place in a spray pot. In the preparation of carbon nanotube film (10*30 cm 2 ) while spraying the mixed solution evenly on the surface of the carbon nanotube bundles. The sprayed composite film is left to stand, air-dried, and cut. The cut composite film was placed in a high-pressure reactor for solvothermal reaction. The solvent in the reaction kettle was a mixed solution of absolute ethanol and water, with a volume ratio of 1:1 (60 mL water: 60 mL absolute ethanol); the reaction temperature was 180 °C, and the reaction time was 4 h. Cool naturally after the reaction, take out the composite film, and dry naturally. Put the dried composite film in a high-temperature reaction furnace, under nitrogen atmosphere, calcination temperature is 500 °C, holding time is 1 h, and the integrated carbon-coated...

Embodiment 3

[0026] Dissolve 1 g of tungsten hexachloride and 2 g of citric acid in 50 mL of mixed solution (25 mL of absolute ethanol and 25 mL of deionized water), ultrasonically disperse, and place in a spray pot. In the preparation of carbon nanotube film (10*30 cm 2 ) while spraying the mixed solution evenly on the surface of the carbon nanotube bundles. The sprayed composite carbon film is left to stand, air-dried and cut. The cut composite film was placed in a high-pressure reactor for solvothermal reaction. The solvent in the reaction kettle was a mixed solution of absolute ethanol and water, the volume ratio was 2:1 (80 mL absolute ethanol: 40 mL water); the reaction temperature was 180 °C, and the reaction time was 4 h. Cool naturally after the reaction, take out the composite film, and dry naturally. Put the dried composite film in a high-temperature reaction furnace, under a nitrogen atmosphere, calcine at a temperature of 500 °C, hold for 2 h, and obtain an integrated carbo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com