Joint structure of concrete rail board

A track slab and concrete technology, applied in tracks, roads, ballast layers, etc., can solve the problems of increasing the hidden dangers of high-speed railway safety, accelerating the rate of joint corrosion, and volatile joints, so as to enhance the waterproof effect and improve the safety. Water effect, effect of reducing the degree of corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

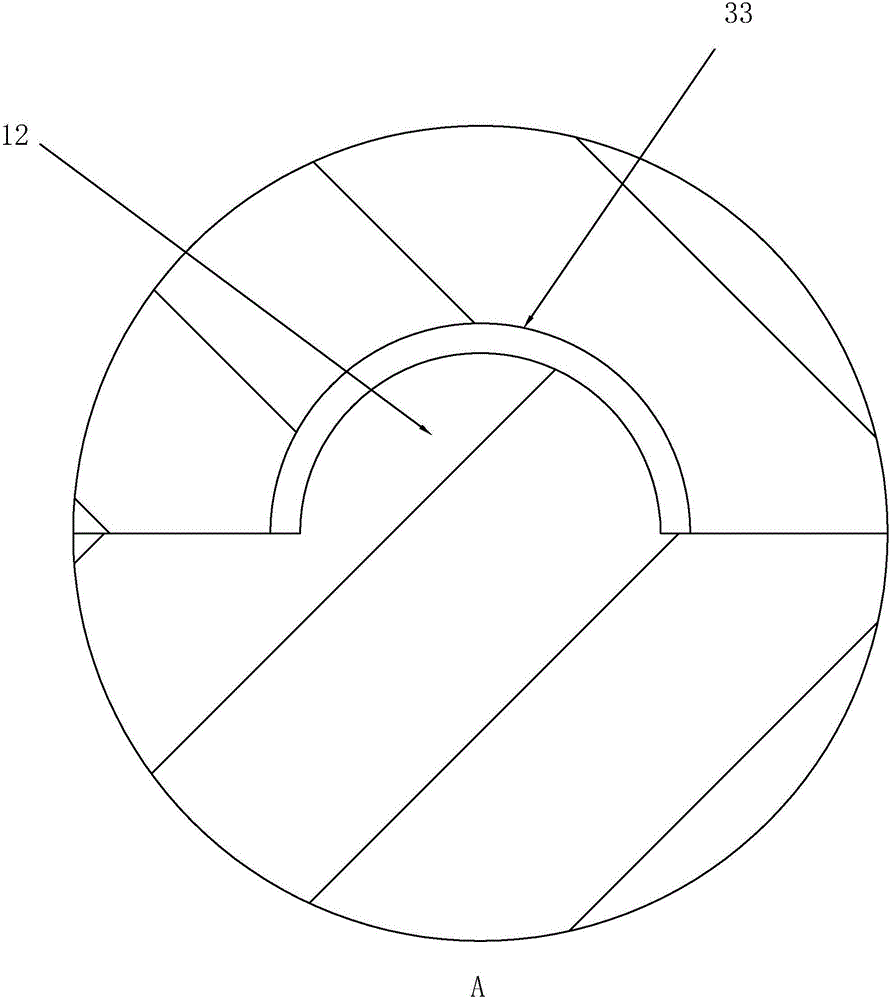

[0046] The preparation steps of the water-absorbent water-swellable water-stop strip here include: kneading 100 kg of methyl vinyl silicone rubber raw rubber and 10 kg of high-molecular water-absorbing resin in a vacuum kneader for 2 minutes, and then kneading 30 kg of fumed silica, 0.2 Stearic acid 1801 in kg, dimethyldimethoxysilane in 3kg, hexamethyldisilazane in 3kg and distilled water in 1kg were added to the vacuum kneader 4 times, and fully stirred after each addition, and mixed Stir and mix the materials evenly. After the rubber materials are kneaded and shaped, heat up to 140°C, heat for 90min, then vacuumize to a vacuum degree of -0.07MPa, vacuumize for 120min, cool down to 75°C with cooling water, and then cool to room temperature , and extruded by an extruder to obtain a finished water-absorbing expansion water-stop strip. Here, the polymer water-absorbing resin can be provided by Renqiu Huabei Chemical Co., Ltd. Certainly, the formula composition of concrete situ...

Embodiment 2

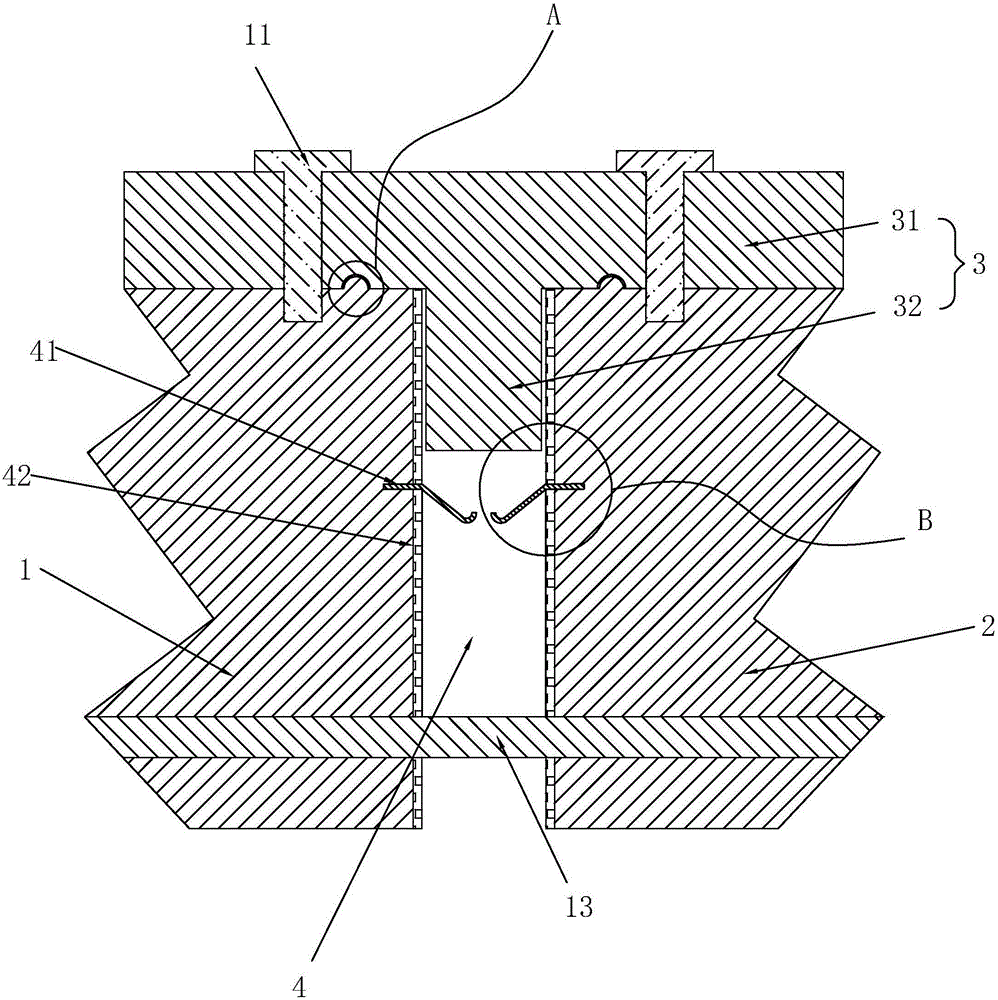

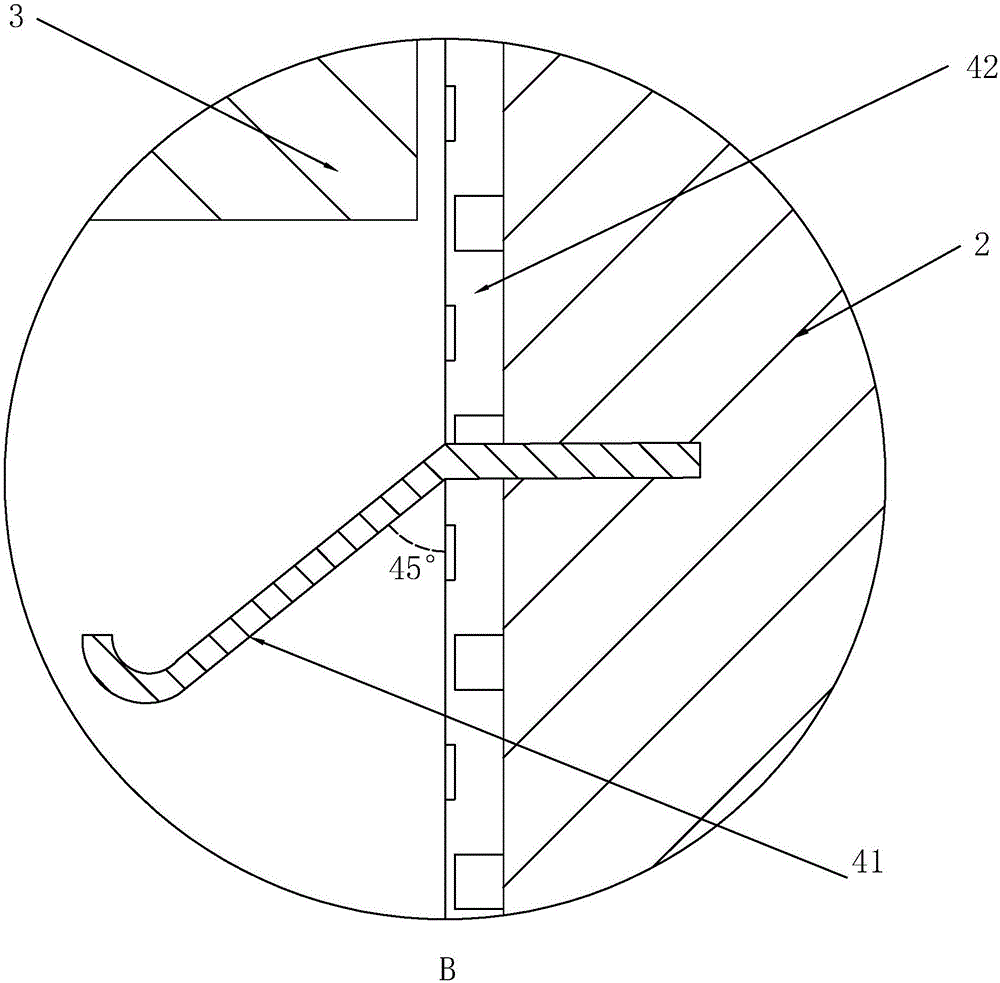

[0052] A joint structure of concrete track slabs, as attached Figure 4 As shown, on the basis of the first embodiment, the concrete track slab 1 and the concrete track slab 2 2 are provided with limiting grooves 43 in the joints 4, and the limiting grooves 43 are located below the water guide sheet 41, and the limiting grooves on both sides The groove 43 is arranged symmetrically with respect to the seam 4 , and the cross section of the limiting groove 43 is arranged as an isosceles trapezoid, and the two bases of the isosceles trapezoid are arranged in a vertical direction. At the same time, the isosceles trapezoid is filled with a number of water-absorbing swellable water-stop balls 5 , and the diameter of the water-absorbing swellable water-stop balls 5 in a dry state is greater than the width of the seam 4 , so that the water-absorbing swellable water-stop balls 5 can be prevented from falling from the seam 4 . Thereby, it is equivalent to setting the second waterproof me...

Embodiment 3

[0054] A joint structure of concrete track slabs, as attached Figure 5 And attached Image 6 As shown, based on the second embodiment, there are several rectangular grooves 21 on the concrete track slab 1 and the concrete track slab 2, and the groove 2 21 is also located under the water-absorbing expansion water-stop strip 3. The bottom of the groove two 21 is fixed with an elastic sheet 22 made of metal, and the periphery of the elastic sheet 22 is provided with a sealing ring 221, where the sealing ring 221 is made of silicon rubber, which can also be determined according to the actual situation. On the one hand, when the water-absorbing expansion water-stop strip 3 absorbs water, the weight will increase, so that the elastic sheet 22 can be pressed in the second groove 21 . On the other hand, when dry, the elastic sheet 22 can slightly lift the water-absorbing water-swelling strip 3, thereby increasing the gap between the water-swelling water-stopping strip 3 and the conc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com