Intermediate case of engine

An engine and intermediary technology, which is applied in the direction of engine components, machines/engines, liquid fuel engines, etc., can solve the problems of design difficulty and cost increase, limited space of support plates, and increase the complexity of airfoil structure, etc., to improve airflow distribution The effect of circumferential unevenness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. Note that the aspects described below in conjunction with the drawings and specific embodiments are only exemplary, and should not be construed as limiting the protection scope of the present invention.

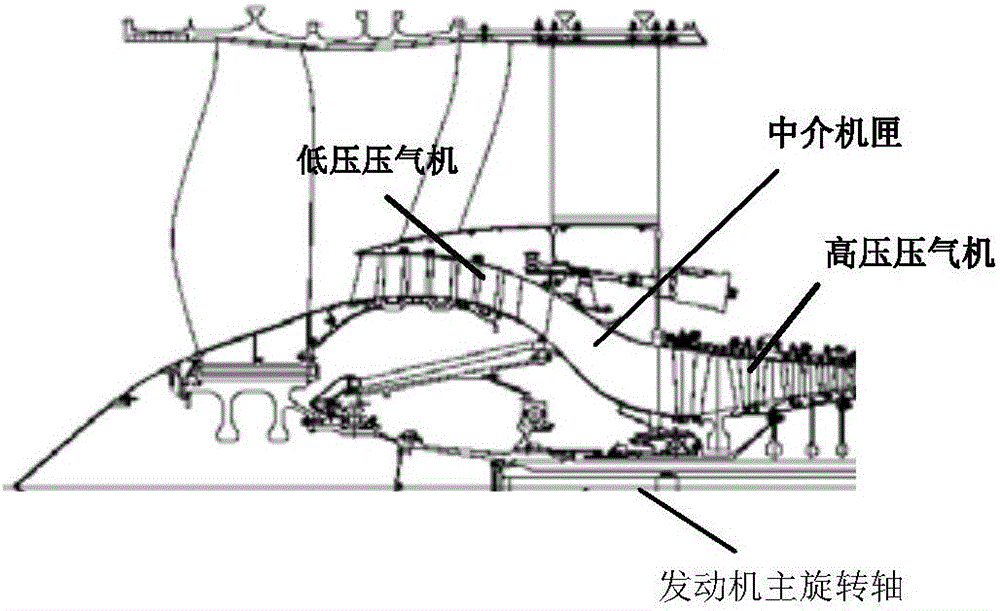

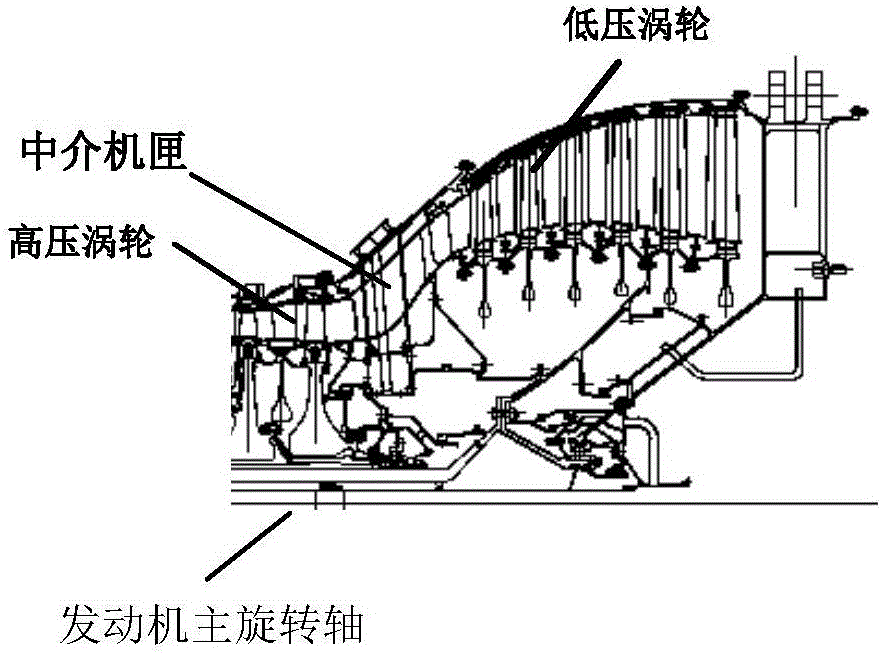

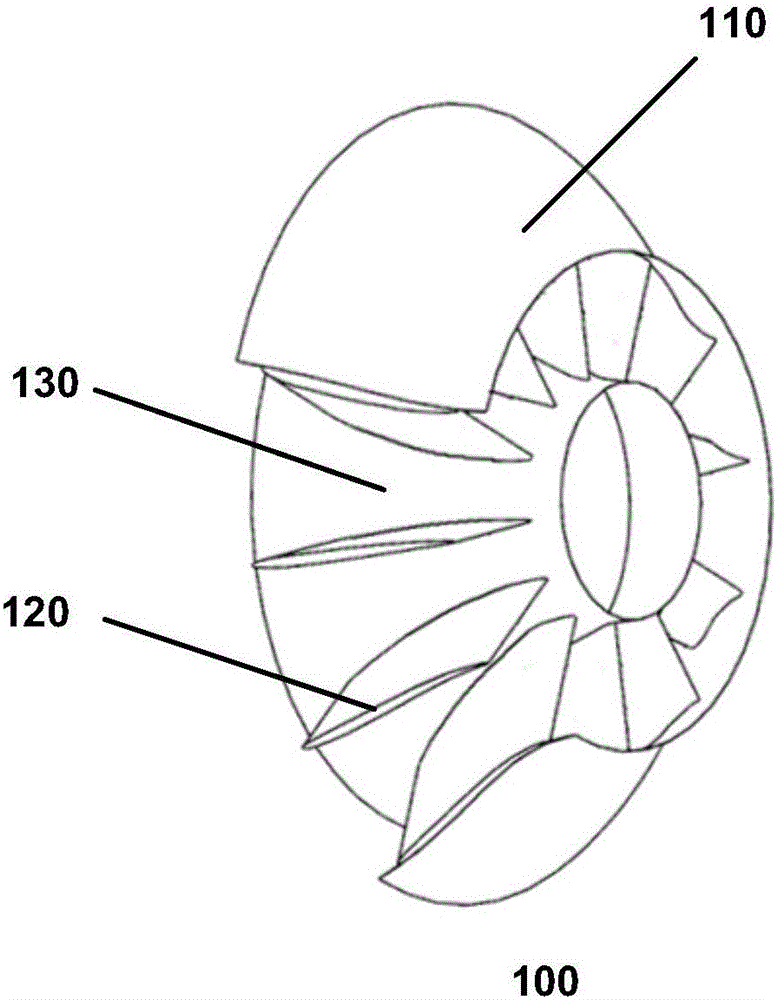

[0040] figure 2 is a schematic diagram showing the structure of the interposer casing 200 according to one aspect of the present invention. figure 2 Only one support plate 210 of the numerous support plates distributed along the circumferential direction of the main engine rotating shaft 130 of the intermediate casing 200 is shown in FIG. Also, for clarity, figure 2 The outer wall and inner wall of the intermediary casing 200 are also omitted in the figure, and a support plate 210 supported between them is directly shown. in addition, figure 2 Also shown in the engine main axis of rotation 230 . From Figure 1C The schematic diagram ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com