Slapper energy change element structure and preparation method thereof

A technology of transducer element and impact sheet, applied in the field of shock sheet transducer element structure and its preparation, which can solve the problems of easy diffusion of plasma, influence on detonation sensitivity and detonation accuracy, and achieve cost control, quality consistency, and Realize the effect of automated production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

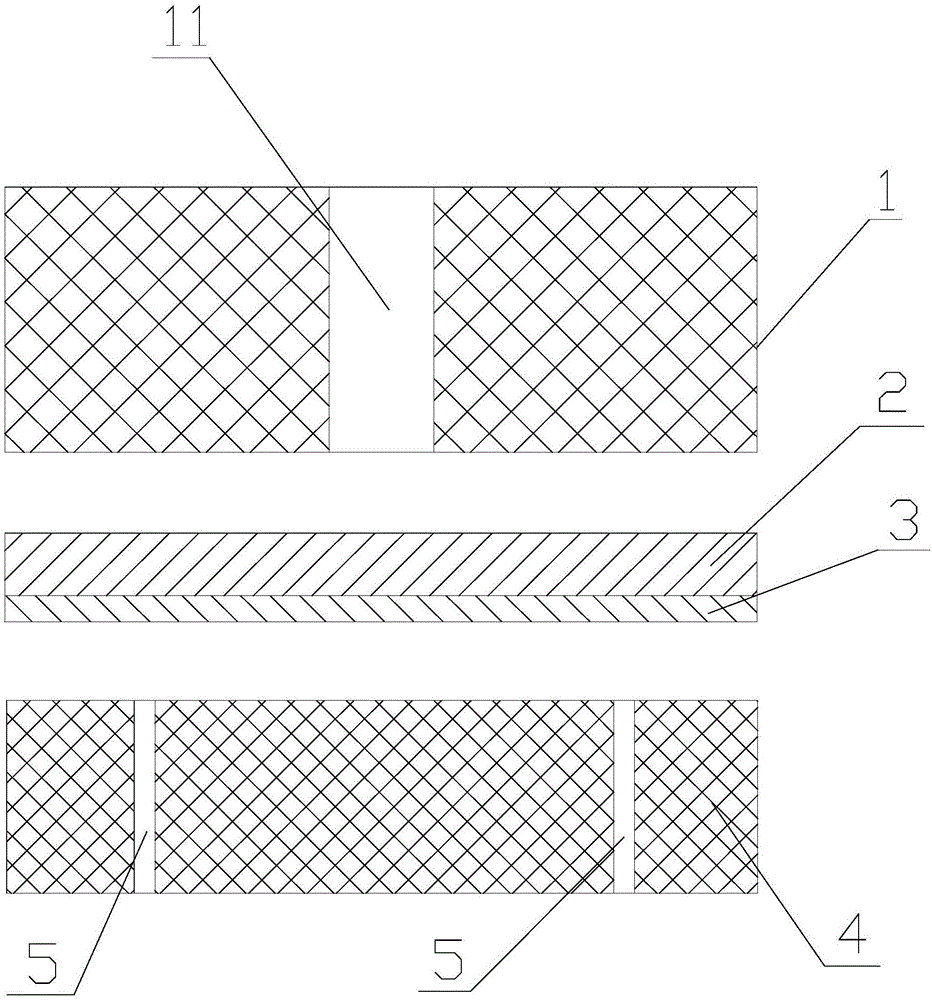

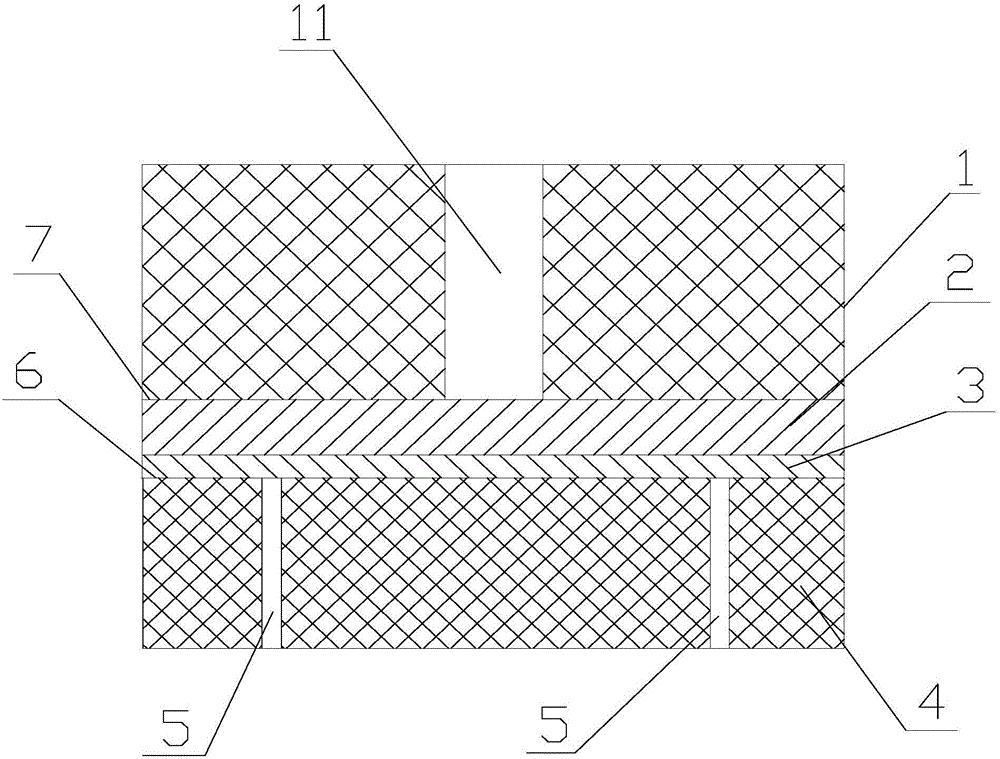

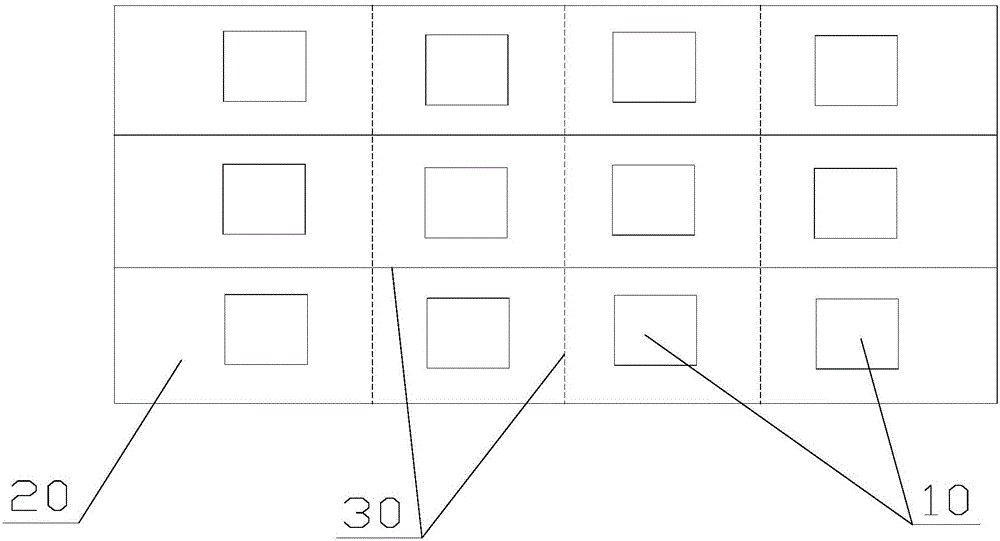

[0035] like Figure 1 ~ Figure 3 As shown, a structure of the transducer element of the shock sheet, including the shear layer 1, the fly layer 2, the explosion foil 3 and the substrate 4, the shear layer 1, the fly layer 2, the explosion foil 3 and the substrate 4 from top to bottom Formed by lamination and bonding in turn, the substrate 4 is provided with several conductive through holes 5, the upper end surface of the conductive through hole 5 is in contact with the lower surface of the explosive foil 3, and the lower end hole surface of the conductive through hole 5 is in contact with the substrate 4. The lower surface is even, and the center of the shear layer 1 is penetrated with a shear through hole 11. The upper surface of the shear through hole 11 is flush with the upper surface of the shear layer 1. Surface contact; fly layer 2 is made of polyimide material. like figure 2 As shown, the contact between the lower surface of the shear layer 1 and the upper surface of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com