Solar cell assembly and manufacture method thereof

A technology for solar cell components and manufacturing methods, applied in electrical components, circuits, photovoltaic power generation, etc., can solve the problems of high installation labor intensity, inability to install, difficult to adapt to different building installation requirements, etc., and achieves reduction of installation cost and weight. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

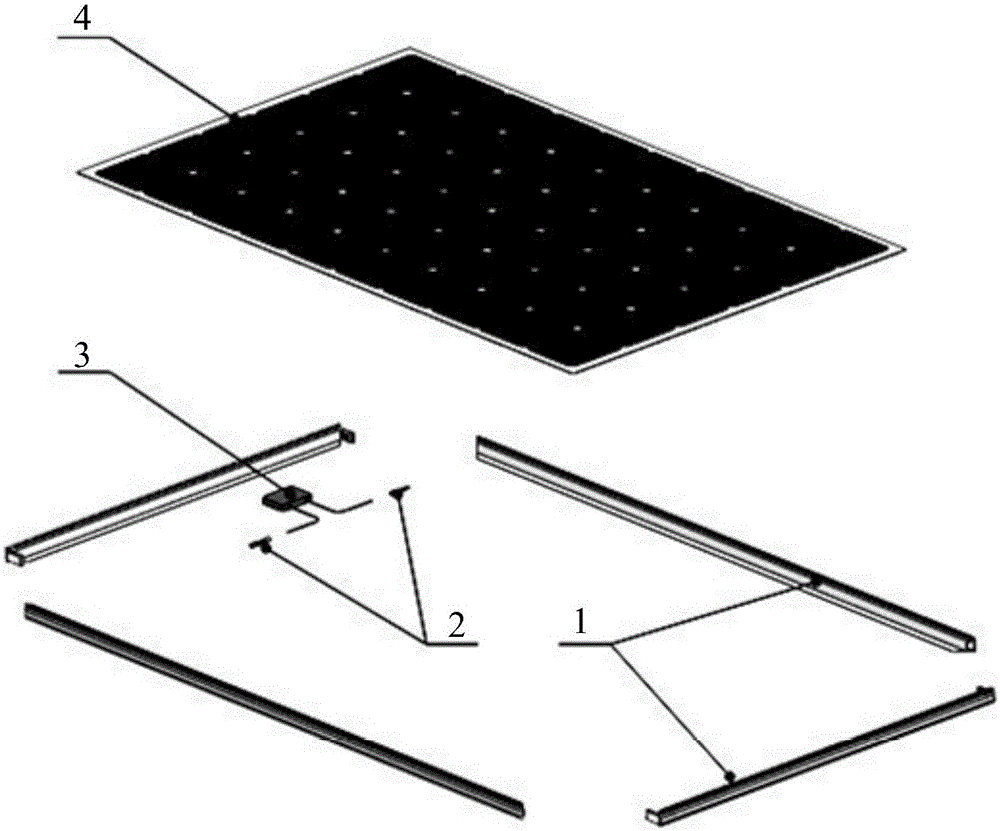

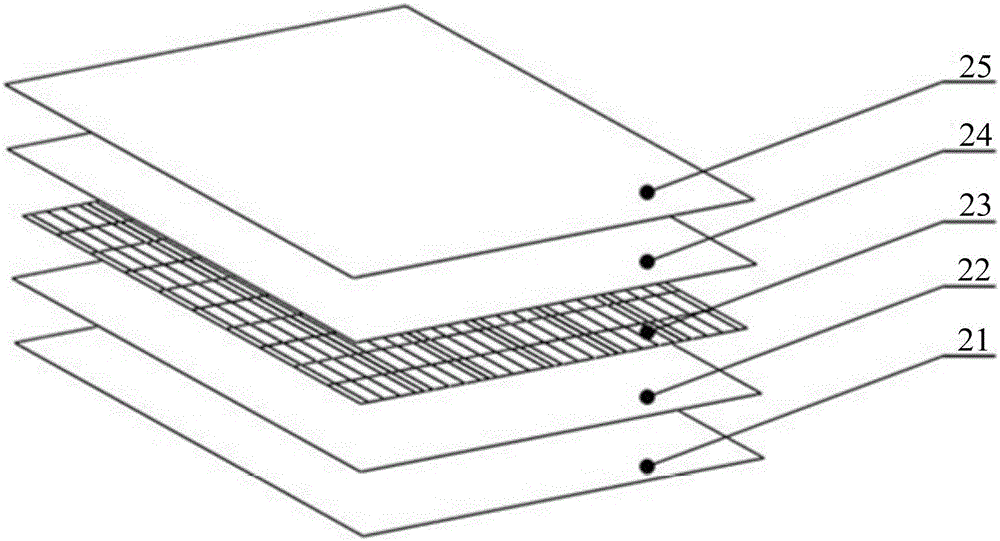

[0025] As mentioned in the background technology, due to the use of toughened glass encapsulation in the existing solar cell modules, during the installation process of buildings and household roofs, there are heavy weights, high labor intensity for installation, and may not be installed due to the limitation of building load-bearing loads. Adapt to the installation requirements of different buildings and other shortcomings. Such as figure 2 As shown, the laminate of the solar cell module in the prior art is formed by sequentially laminating ultra-clear tempered patterned glass 21 , EVA film 22 , solar cell strings 23 , EVA film 24 and back sheet 25 .

[0026] In order to solve the above problems, the technical solution of the present invention relates to the design and manufacturing technology of solar cell components, and specifically provides a design and manufacturing method of a novel light-weight solar cell component.

[0027] The purpose of the technical solution of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com