Soilless planting method based on non-woven fabric

A soilless planting, non-woven technology, applied in the fields of botanical equipment and methods, soilless cultivation, planting substrate, etc., can solve the problems of construction and maintenance trouble, roof collapse, regular maintenance, etc., to achieve convenient and fast construction, guarantee The effect of nutrition supply and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

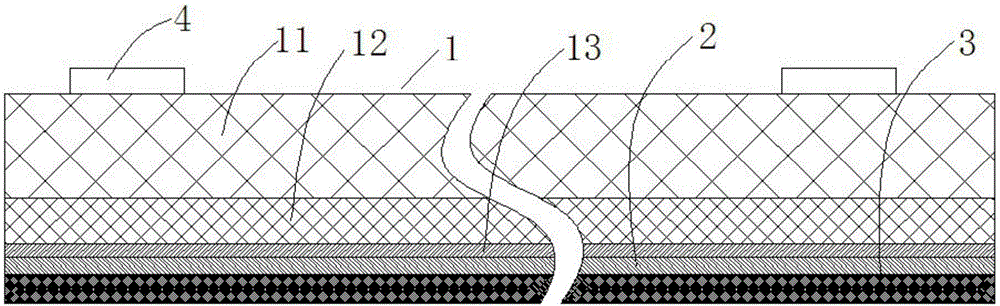

[0023] The present invention will be further elaborated below in conjunction with accompanying drawing, wherein, the direction of the present invention is with figure 1 as standard.

[0024] The non-woven fabric 1 of the present invention is used for planting plants. The non-woven fabric 1 is uniformly mixed with polyester, carbon fiber, viscose fiber and low-melting point fiber, and then compiled through a non-woven fabric weaving process. The carbon fiber has high temperature resistance and aging resistance. , It is not easy to rot and age under the sun, which can prolong the planting time (use of non-woven fabric 1). The melting point of viscose fiber, carbon fiber and polyester is generally greater than 220 degrees Celsius, and the melting point of low melting point fiber is generally 110 degrees Celsius; in addition, polyester , carbon fiber, viscose fiber and low melting point fiber are impregnated with flame retardant, which can achieve the purpose of fire prevention. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com