Pogo pin mold, machining process thereof and pogo pin assembly process

A processing technology and probe technology, applied in the field of pogopin probe needle molds, can solve the problems of low assembly efficiency, easy dislocation between plates and difficult fixing, etc. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

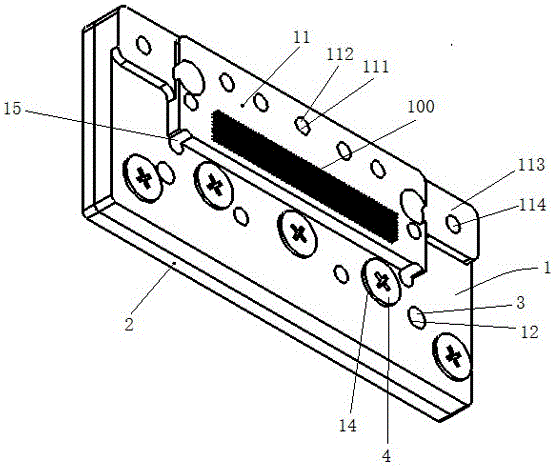

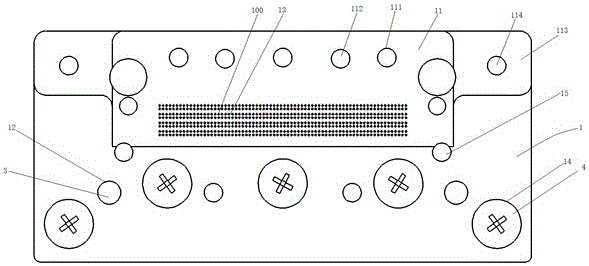

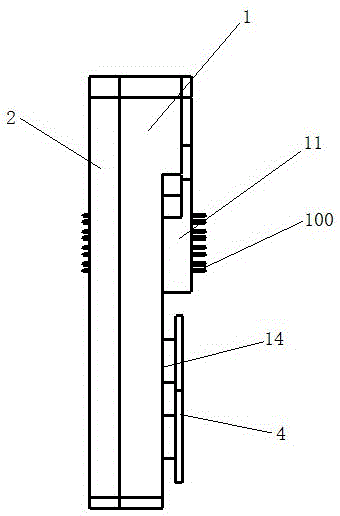

[0037] see Figure 1~Figure 4 , a pogopin probe needle mold according to the present invention, the needle mold includes: a lower cover plate 1, a square boss 11 is protruded on one side of the surface, and several lower plates are provided on the other side along the length direction of the lower cover plate 1. Through holes 12, one side of the boss 11 is provided with a number of lower pinholes 13 along the thickness direction of the boss 11 for the pogopin probe 100 to pass through; The upper pinhole (not shown) and the upper through hole (not shown) corresponding to the lower pinhole 13 and the lower through hole 12 respectively; The connection between the upper cover plate 2 and the lower cover plate 1 is formed by passing the fixing member 3 through the upper and lower through holes; the Pogopin probe 100 passes through the upper pinhole 13 of the lower cover plate 1 through the upper pinhole of the upper cover plate 2 .

[0038]Further, in one embodiment of the presen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com