Uniformly-stressing tightening device

An elastic device and uniform force technology, applied in metal processing and other directions, can solve the problems of affecting work efficiency, different tightness, poor turning effect, etc., and achieve the effect of improving work efficiency, beautiful appearance and good turning effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

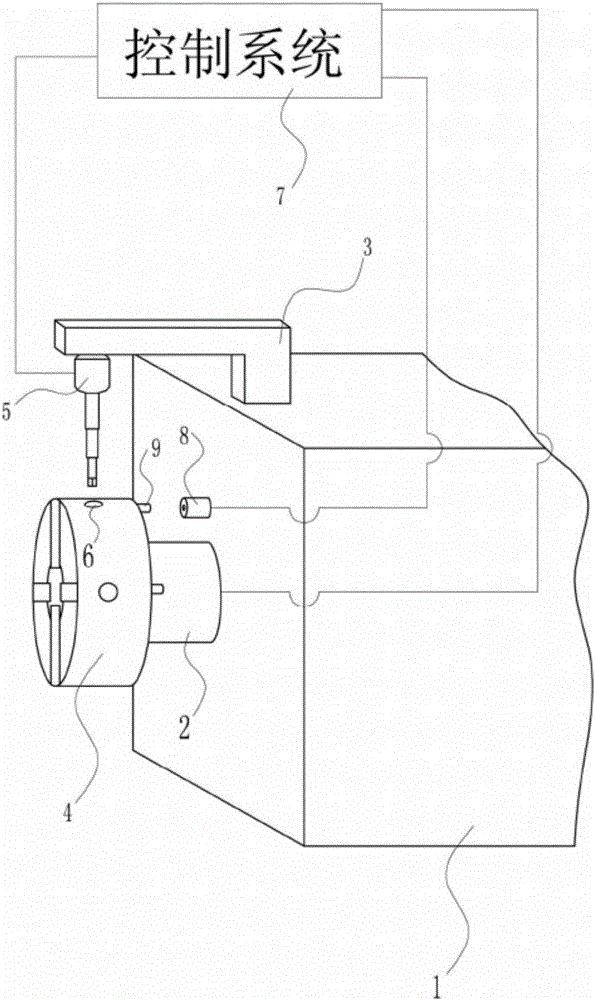

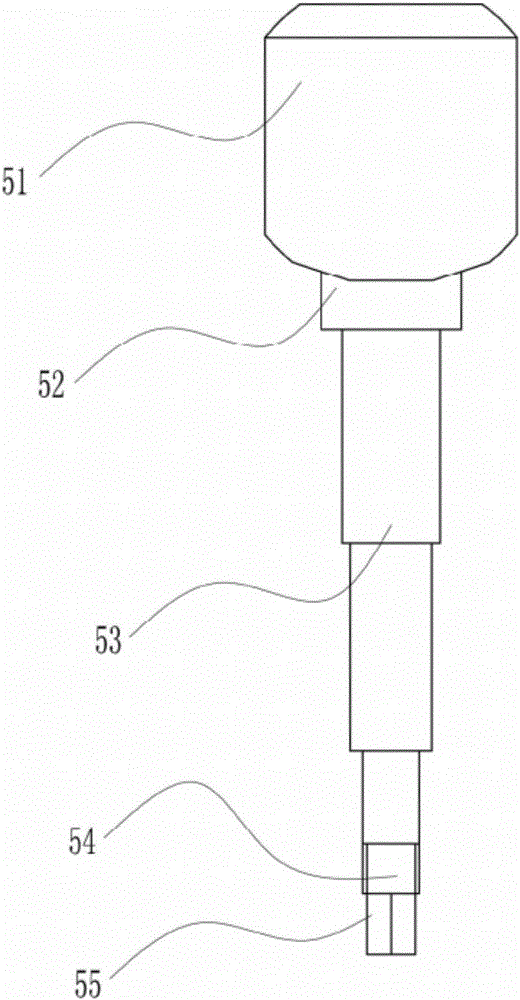

[0015] A uniformly stressed elastic device, such as Figure 1-2 As shown, it includes a lathe headstock 1, a rotating shaft 2, a crossbeam 3, a chuck 4, an elastic device 5, a wrench insertion hole 6 and a control system 7, and the front part of the lathe headstock 1 is provided with a rotating shaft 2, and the lathe headstock 1 A crossbeam 3 is provided above the top of the crossbeam 4, and the chuck 4 is installed on the rotating shaft 2. An elastic device 5 is provided under the front end of the crossbeam 3. Four wrench insertion holes 6 are evenly spaced on the outer wall of the chuck 4. The rotating shaft 2 and the elastic The device 5 is connected with the control system 7 respectively; the elastic device 5 includes an electric wrench 51, a lifting motor 52, a lifting rod 53, a groove 54 and a straight hexagonal wrench 55, and one end of the electric wrench 51 is connected to the beam 3, and the other side is connected to the lifting wrench. The motor 52 is connected, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com