A precision monitoring and diagnosis method for the electric spindle of ultra-high-speed CNC grinding machine based on differential chaos

A technology of CNC grinding machine and diagnosis method, which is applied in the control of workpiece feed movement, grinding machine parts, grinding/polishing equipment, etc., can solve the problem of poor detection accuracy, poor coaxiality, and low phase trajectory distinction. and other problems, to achieve the effect of improving detection sensitivity and accuracy, improving detection sensitivity, and reducing the difficulty of discrimination.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

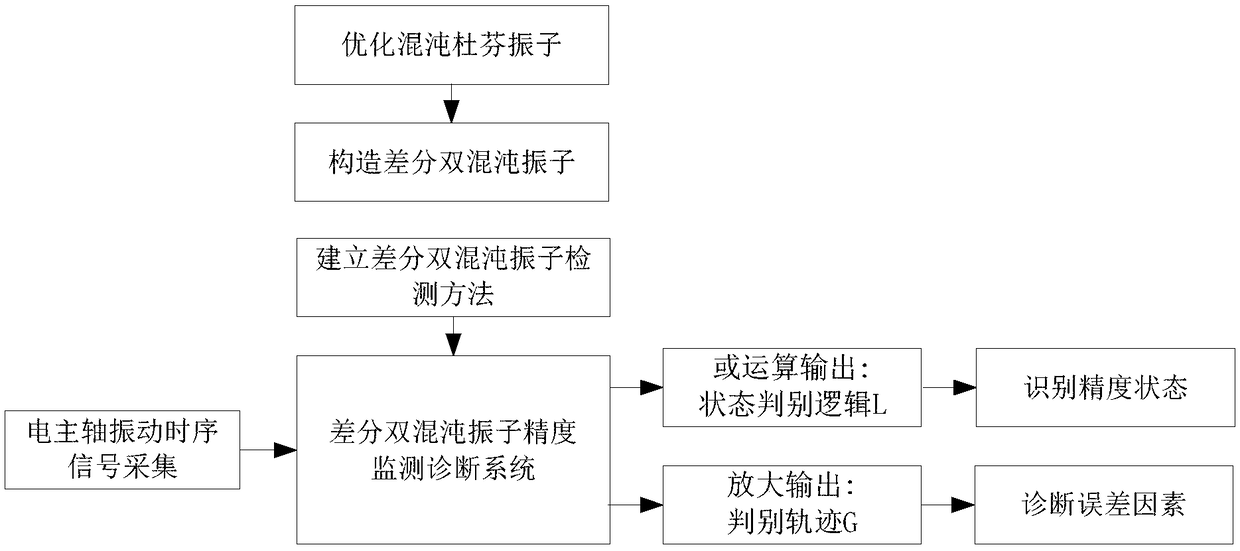

[0053] Example: such as figure 1 As shown, it is the flow of monitoring and diagnosing the accuracy of the electric spindle of an ultra-high-speed CNC grinding machine based on differential double chaotic oscillators in this embodiment. Taking the accuracy monitoring and diagnosis of an electric spindle of a HBW2350-H CBN ultra-high-speed cylindrical grinding machine as an example, the specific implementation The process is as follows:

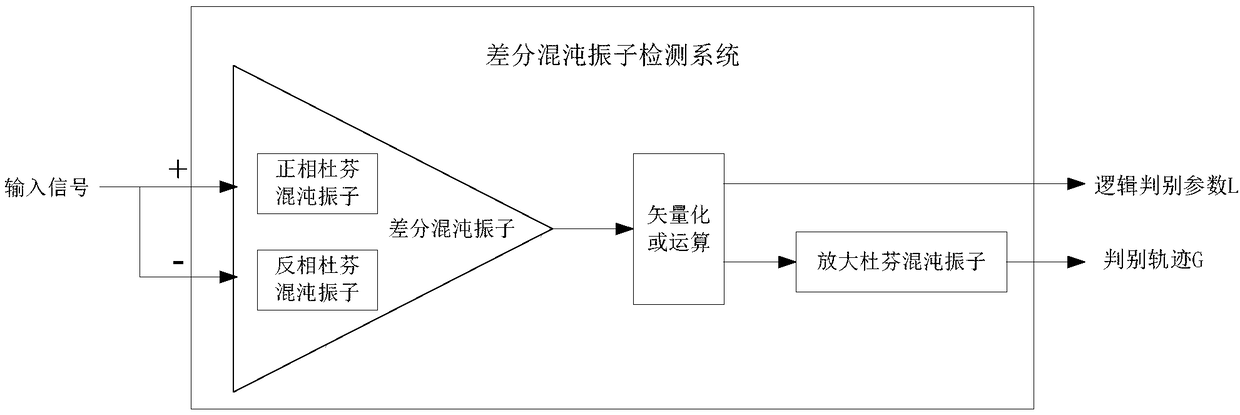

[0054] 1) Based on the principle of differential amplification, construct a differential dual chaotic oscillator that can achieve high-sensitivity bidirectional detection, and establish a weak signal detection method based on differential dual chaotic oscillators.

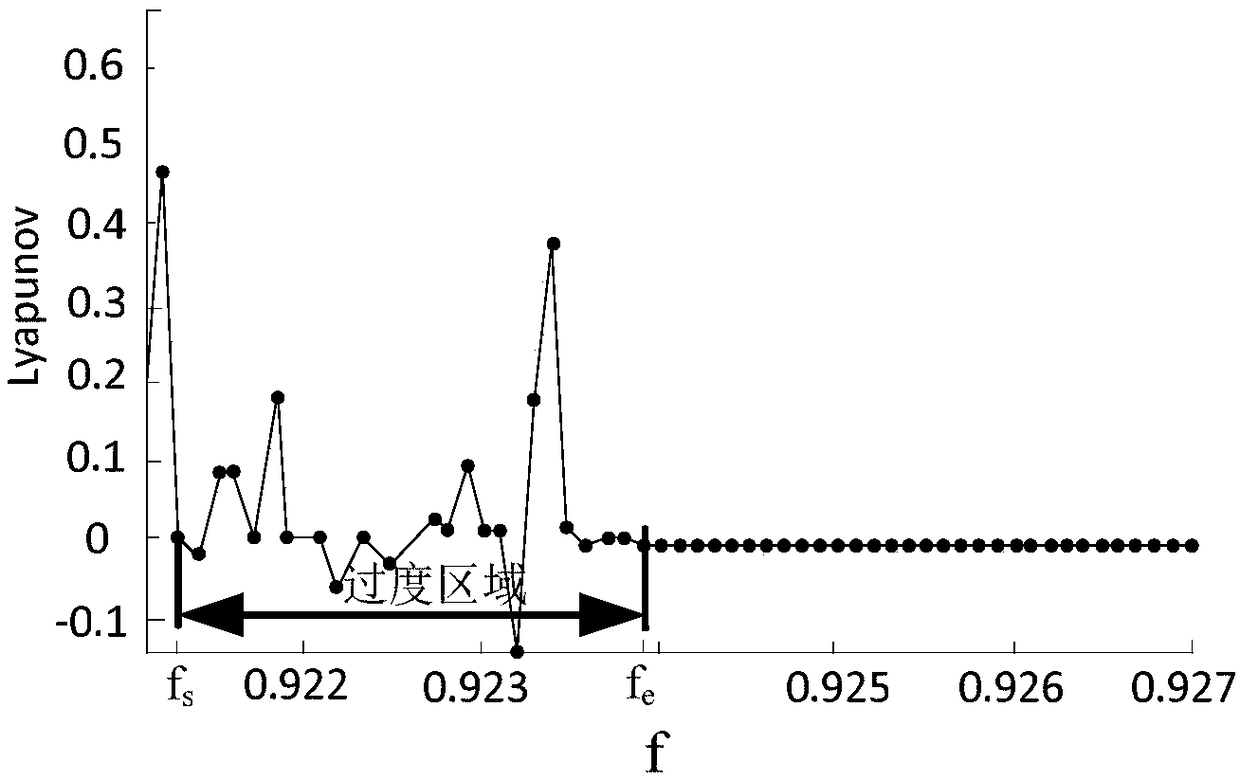

[0055] a) In order to improve the sensitivity and anti-noise ability of the system to the input signal, the nonlinear restoring force term of the traditional Duffin oscillator is changed from -x+x 3 enhanced to -x 5 +x 7 , optimized as a Duffin chaotic oscillator as follows:

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com