Air joint type flexible mechanical arm based on rope drive

A flexible manipulator and rope-driven technology, applied in the field of manipulators, can solve problems such as the weight of the manipulator, affecting the flexibility of the manipulator, mobility, safety and carrying capacity of man-machine cooperation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

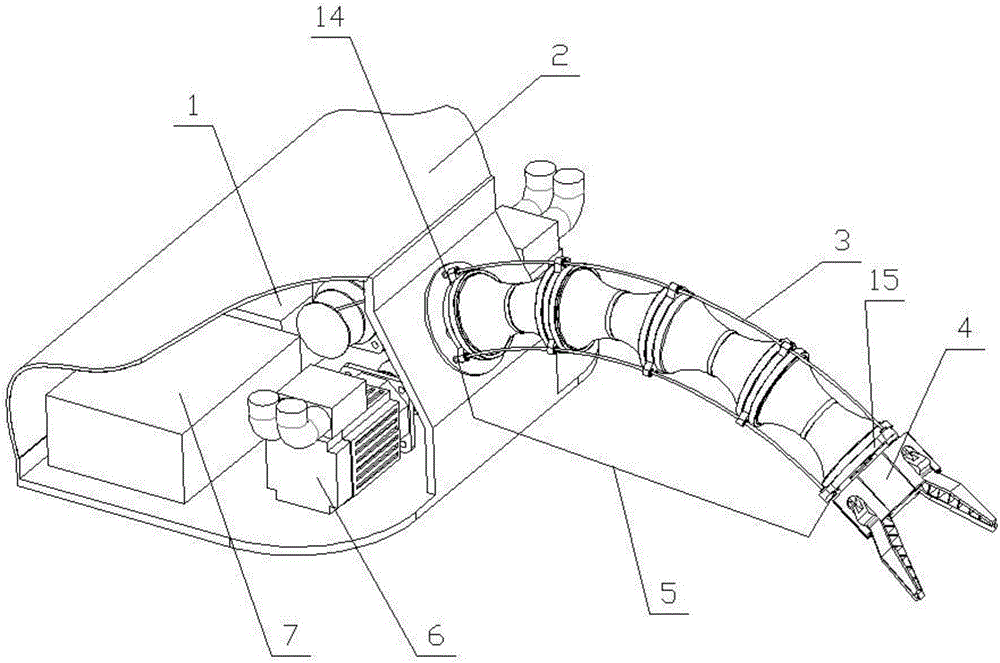

[0020] exist figure 1 In the shown schematic diagram of the air-joint flexible manipulator based on rope drive, the machine base 2 is the shell, and three motors 6, power supply 1 and control system 7 are arranged in the machine base; the arm-body mechanism 5 consists of several groups of The joint units are connected in series, two joint units constitute a two-stage robotic arm, three joint units constitute a three-stage robotic arm, and this embodiment is a four-stage robotic arm; one end of the arm body mechanism is connected to the machine base , the other end of which is connected to the end effector 4 to grab the target object; the driving rope 3 is three evenly distributed in the circumferential direction, one end of each rope is fixed at the end of the arm body mechanism, and the other end passes through each The wire holes of the joint unit are connected to the rollers of the three motors in the frame;

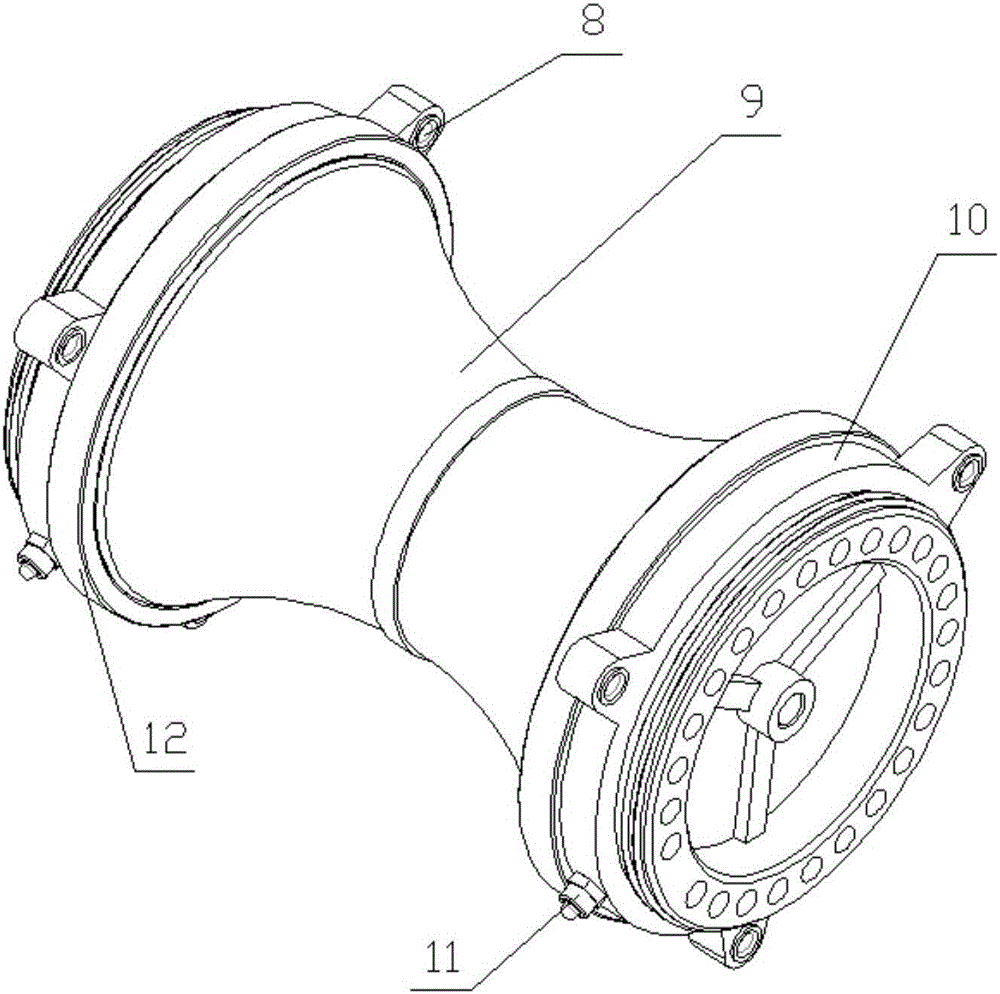

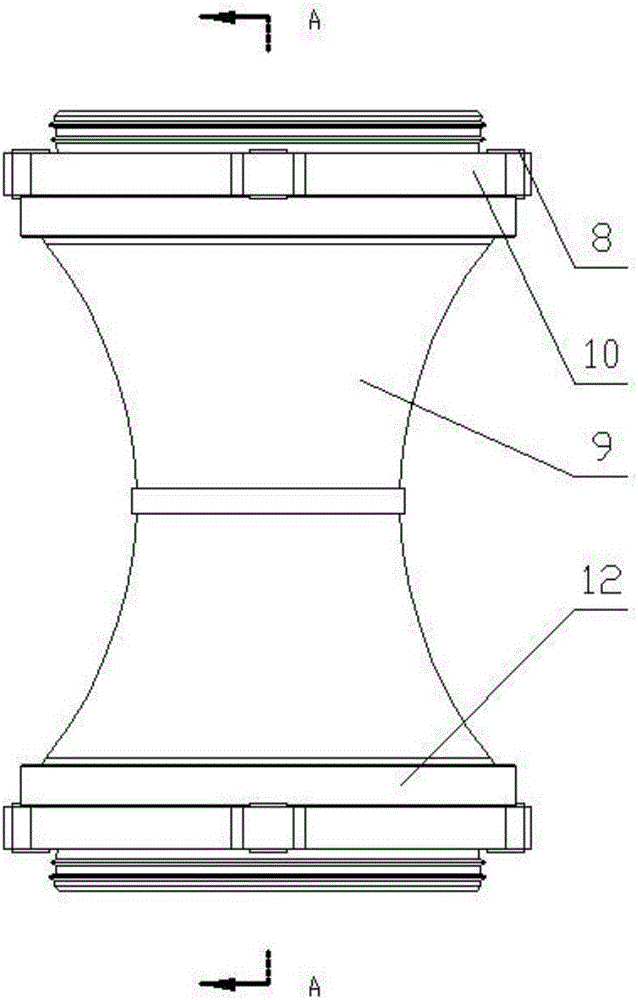

[0021] Such as figure 2 , 3 As shown in and 4, the joint uni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com