A device capable of eliminating polysilicon carbon heads

A polysilicon carbon and polysilicon technology, applied in the fields of silicon compounds, inorganic chemistry, non-metallic elements, etc., can solve problems such as affecting the quality of polysilicon, increasing production costs, and waste of polysilicon, saving human resources and economic costs, and avoiding carbon headstock. , the effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

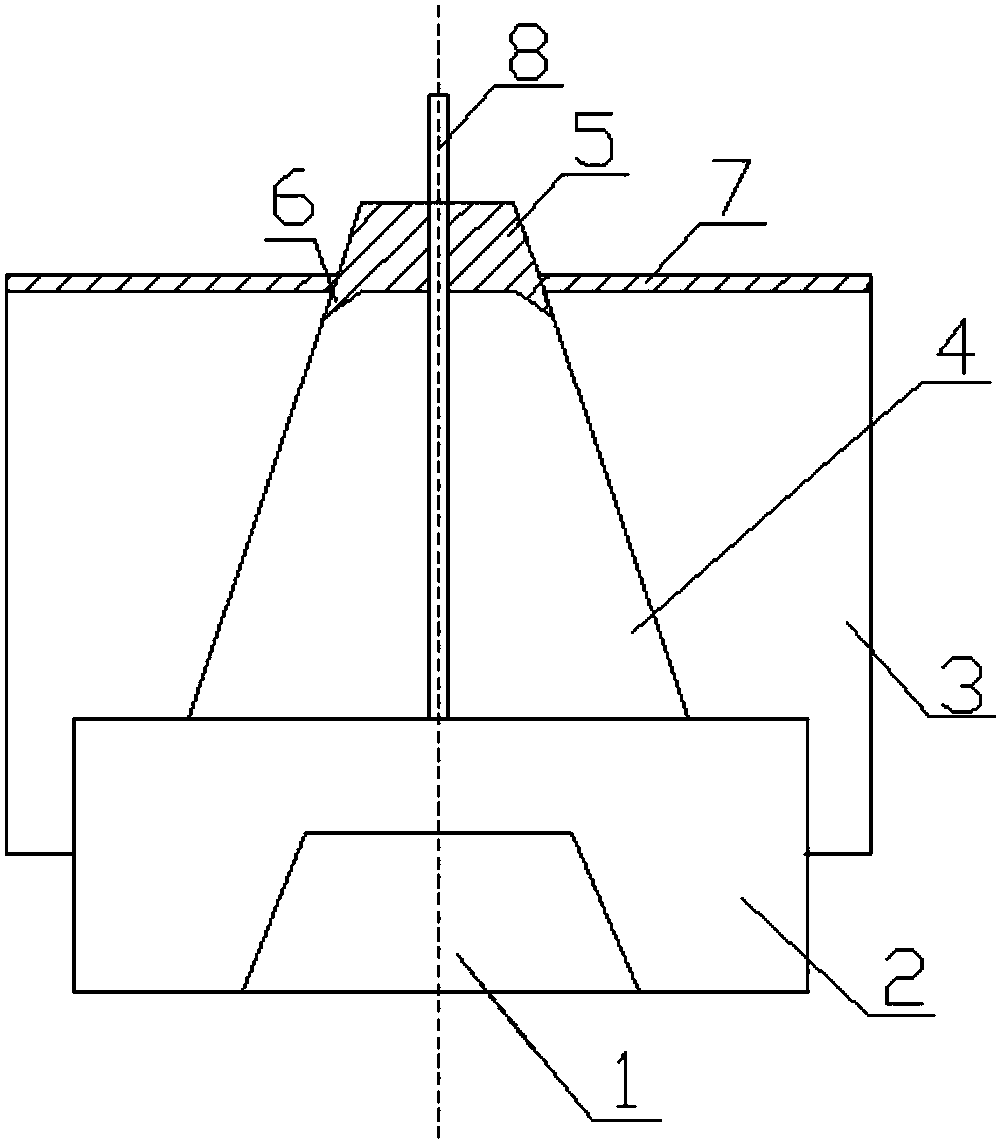

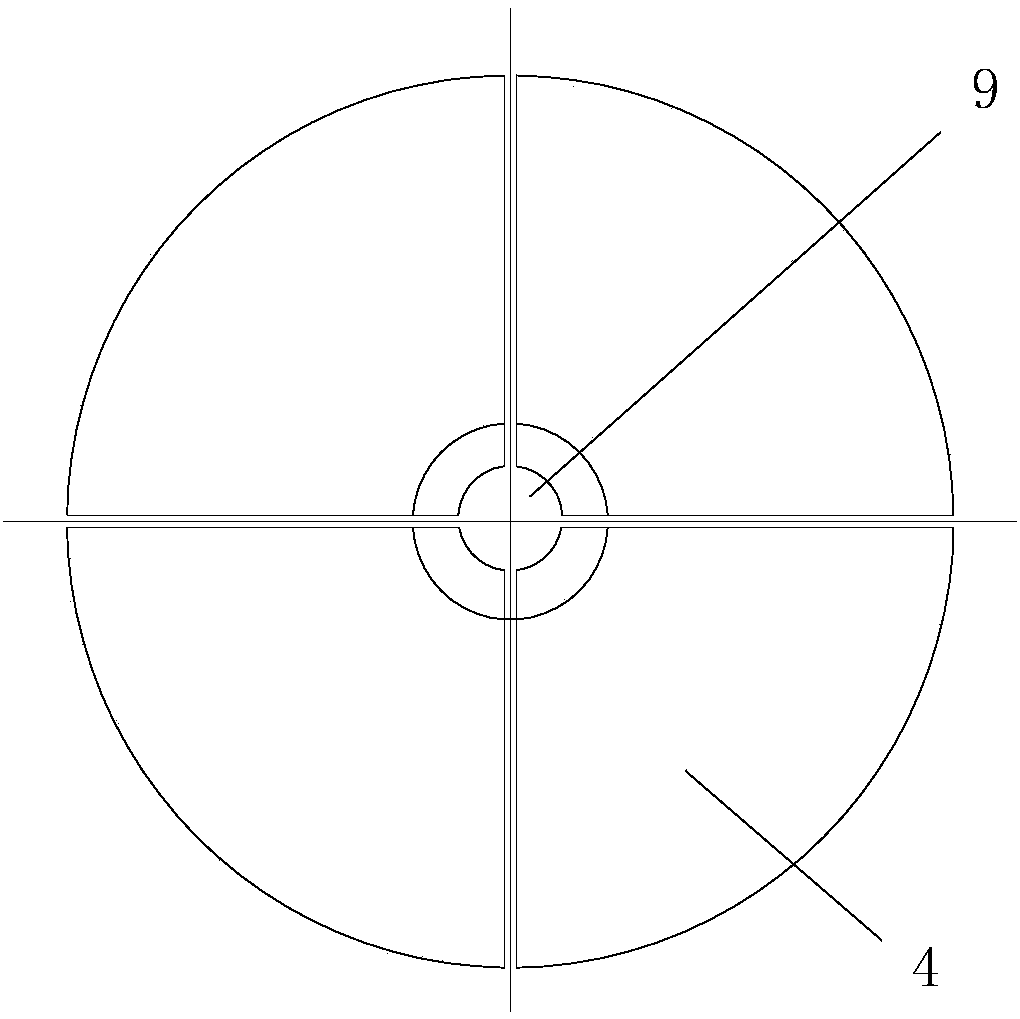

[0021] In this embodiment, refer to figure 1 with figure 2 , The device that can eliminate polysilicon carbon stubs includes an electrode 1, a graphite base 2 sleeved with the electrode 1, a clasp group placed on the graphite base 2, and a set of flaps that matches and matches the graphite base 2 The graphite cap 3 connected to the graphite base 2 has a cavity 9 for accommodating the silicon core 8 in the middle of the clamping petal group; the clamping petal group is formed by butting the graphite part 4 and the polysilicon part 5, and the graphite part 4 constitutes the card The main structure of the petal group is placed on the graphite base 2. The polysilicon part 5 constitutes the upper structure of the card petal group, and the polysilicon part 5 is connected to the top of the graphite part 4; the upper surface of the graphite cap 3 is covered with a polysilicon protective shell 7. The polysilicon protective shell 7 is connected to the polysilicon part 5 of the card flap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com