Recycled aggregate pretreatment equipment

A technology for recycled aggregates and pretreatment, applied in sustainable waste treatment, solid waste management, climate sustainability, etc. Improve quality, reduce impact, and achieve the effect of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

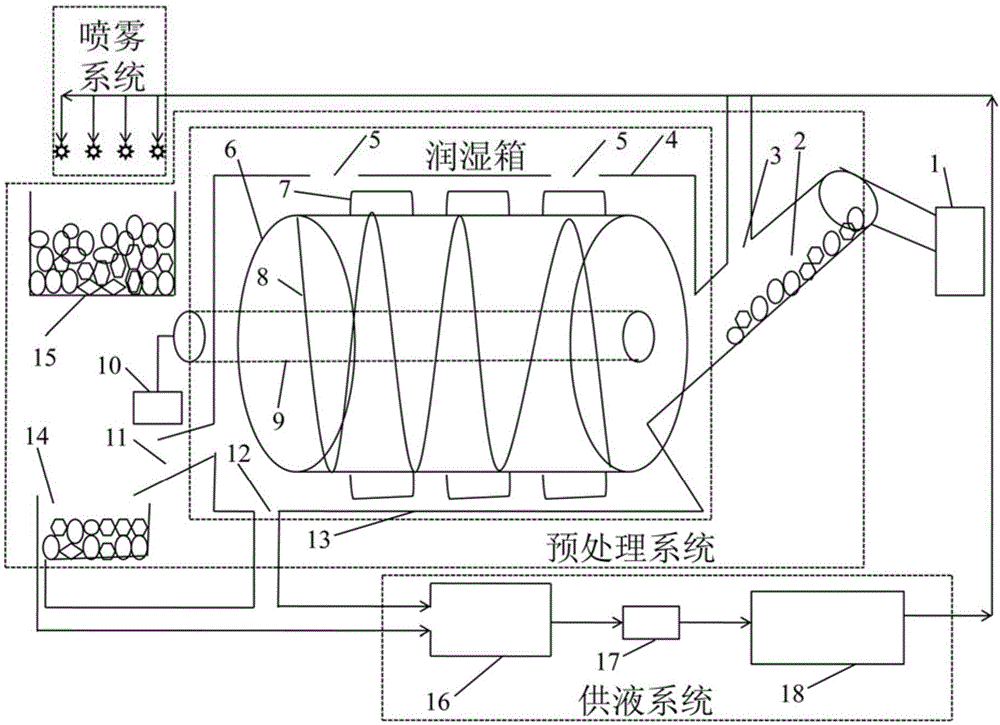

[0028] Please refer to figure 1 , A pretreatment equipment for recycled aggregates of the present invention includes a pretreatment system, a spray system, and a liquid supply system. The pretreatment system is used to process the recycled aggregate, remove the small particles that do not meet the particle size requirements, the surface-attached micropowder, sundries, etc., so that the recycled aggregate can absorb a certain amount of water or strengthen liquid. The spray system is used to keep the surface of the recycled aggregate treated by the pretreatment system moist. The liquid supply system is used to provide a liquid source to the pretreatment system and the spray system.

[0029] The pretreatment system includes a wetting box, a rolling net bucket 6 arranged horizontally in the moistening box along an axial direction, a driving component that drives the rolling net bucket to rotate, a receiving bin 14, and a storage yard 15. The humidification box includes a box body 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com