Hydrogen-bond-crosslinked type water-in-water multicolor paint and preparation method thereof

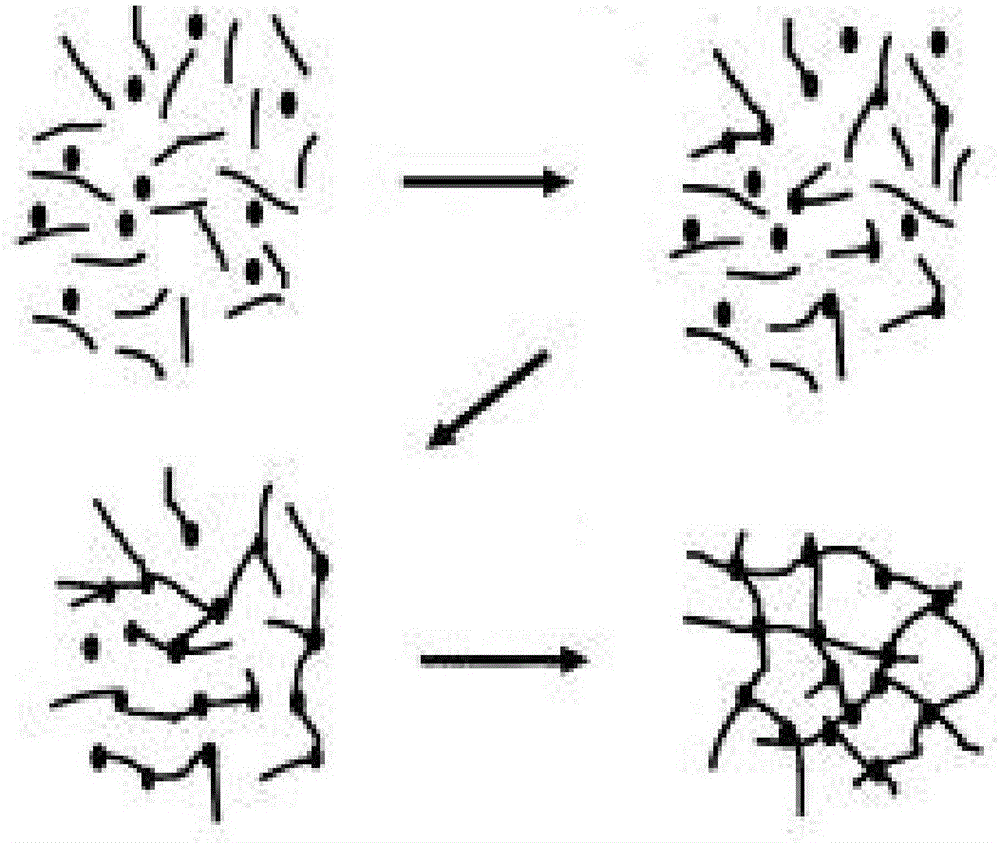

A multi-color paint, cross-linking technology, applied in multi-color effect paint, coating and other directions, can solve the problems of multi-color paint stability and low color particle strength, improve the strength and protection range, expand the preparation process and use range, the effect of reducing the rate of the crosslinking reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

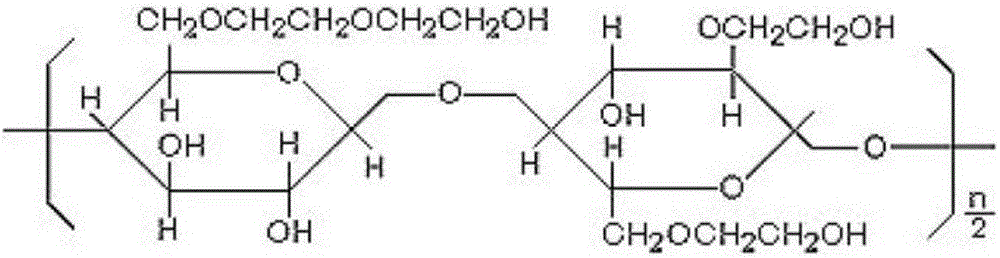

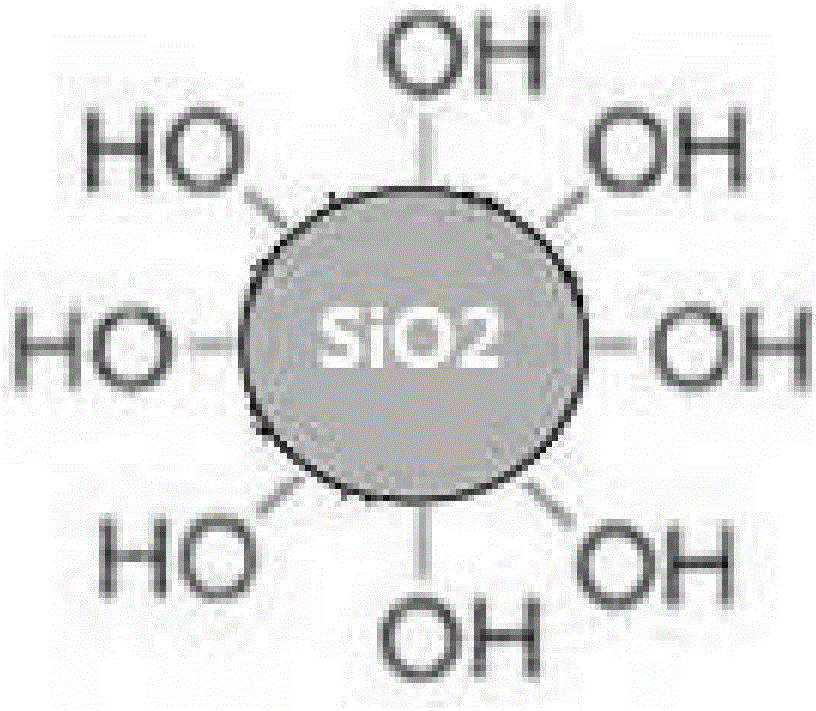

[0028] (1) The color particles of the A component are prepared in the following manner: adding water, wetting agent and dispersing agent accounting for 50% of the total weight of water into a dispersing cylinder, stirring for 5 minutes at a rotating speed of 300 to 400 rmp, and then Add filler, disperse the system to a fineness of less than 40um at a speed of 800-1000rmp, add cellulose ether, pH adjuster and remaining water, stir for 30 minutes, then add pure acrylic emulsion, retarder, defoamer and Inorganic sol, stir evenly at a rotating speed of 300-800 rmp, add pigment to color to obtain component A, and automatically gel the component A and then cut and granulate to obtain the colored particles of component A. Wherein, the retarder adopts silane coupling agent (for example: silane coupling agent KH550, silane coupling agent KH560 in the prior art) or urea, and the inorganic sol adopts silica sol (for example: in the prior art) Alkaline silica sol with a solute mass fracti...

Embodiment 1

[0048] A hydrogen bond cross-linked water-in-water colorful paint is composed of the following raw materials according to the mass percentage:

[0049] A component mass percentage water 61.1% lubricant 0.5% Dispersant 0.5% filler 5.0% Cellulose ether 1.0% defoamer 0.3% pH adjuster 0.1% Pure acrylic emulsion 20.0% Alkaline silica sol (inorganic sol) 10.0% Silane coupling agent KH550 (retarder) 0.5% pigment 1.0% component B mass percentage water 50% Silicone acrylic emulsion 45% Coalescent 3.5% fungicide 0.5% Thickener (polyurethane type thickener) 1.0%

[0050] Wherein, in the above-mentioned A component raw materials, the wetting agent, dispersing agent, pigment, filler, defoamer, pH adjuster are the wetting agent, dispersing agent, pigment, filler, Defoamers and pH adjusters are sufficient. In the above-mentioned B component raw materials, the film-for...

Embodiment 2

[0056] A hydrogen bond cross-linked water-in-water colorful paint is composed of the following raw materials according to the mass percentage:

[0057] A component mass percentage water 58.8% lubricant 0.5% Dispersant 0.5% filler 5.0% Cellulose ether 0.8% defoamer 0.3% pH adjuster 0.1% Pure acrylic emulsion 20.0% Alkaline silica sol (inorganic sol) 12.0% Silane coupling agent KH560 (retarder) 1.0% pigment 1.0% component B mass percentage water 50% Silicone acrylic emulsion 45% Coalescent 3.5% fungicide 0.5% Thickener (polyurethane type thickener) 1.0%

[0058] Wherein, in the above-mentioned A component raw materials, the wetting agent, dispersing agent, pigment, filler, defoamer, pH adjuster are the wetting agent, dispersing agent, pigment, filler, Defoamers and pH adjusters are sufficient. In the above-mentioned B component raw materials, the film-for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com