Double-enzyme co-immobilizing method and immobilized enzyme prepared through method

A technology of immobilizing enzymes and setting temperature, applied in the field of bioengineering, can solve the problem of high cost of immobilizing multi-enzymes, and achieve the effects of improving catalytic efficiency, broadening tolerance and satisfying operating conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

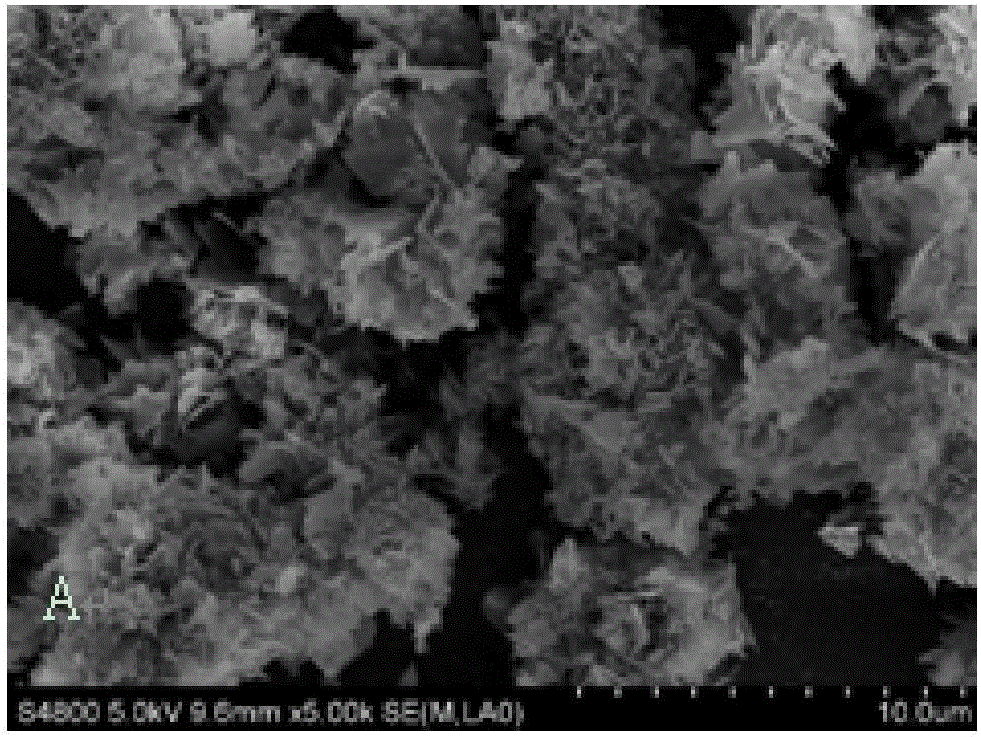

[0035] Add 0.9ml, 0.2 mol / L calcium chloride solution, reacted for 12 hours at 25°C, centrifuged at 12000rpm for 10min, and washed three times with distilled water centrifugally to obtain α-acetolactate decarboxylase-calcium phosphate-proline endonuclease (PSEP-Ca 3 (PO 4 ) 2 -ALDC) immobilized carrier, its electron micrograph is as figure 1 shown. It can be seen from the figure that when the initial enzyme is not contained, the formed carrier is mainly a stacked lamellar structure, the structure is relatively dense, and the specific surface area is not high.

Embodiment 2

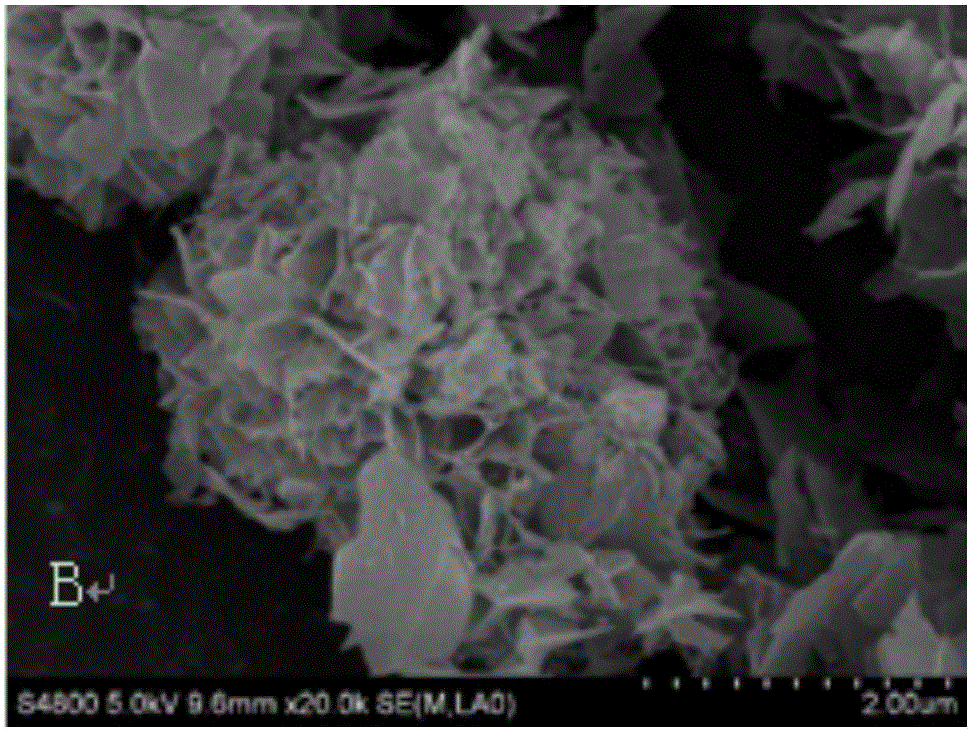

[0037] Add 0.9ml, 0.2 mol / L calcium chloride solution, reacted for 12 hours at 25°C, centrifuged at 12000rpm for 10min, and washed three times with distilled water to obtain α-acetolactate decarboxylase-calcium phosphate-proline endonuclease (PSEP-Ca 3 (PO 4 ) 2 -ALDC) immobilized enzyme, in the prepared immobilized enzyme, the content of immobilized enzyme per milligram of calcium phosphate loaded is 13.38mg, and its electron micrograph is as follows figure 2 shown. It can be seen from the figure that at this initial enzyme concentration, compared with the structure without enzyme, the lamellar structure is loose and the specific surface area increases. At this time, the activities of the two enzymes that have been immobilized are about 30% of the activities of the free enzymes.

Embodiment 3

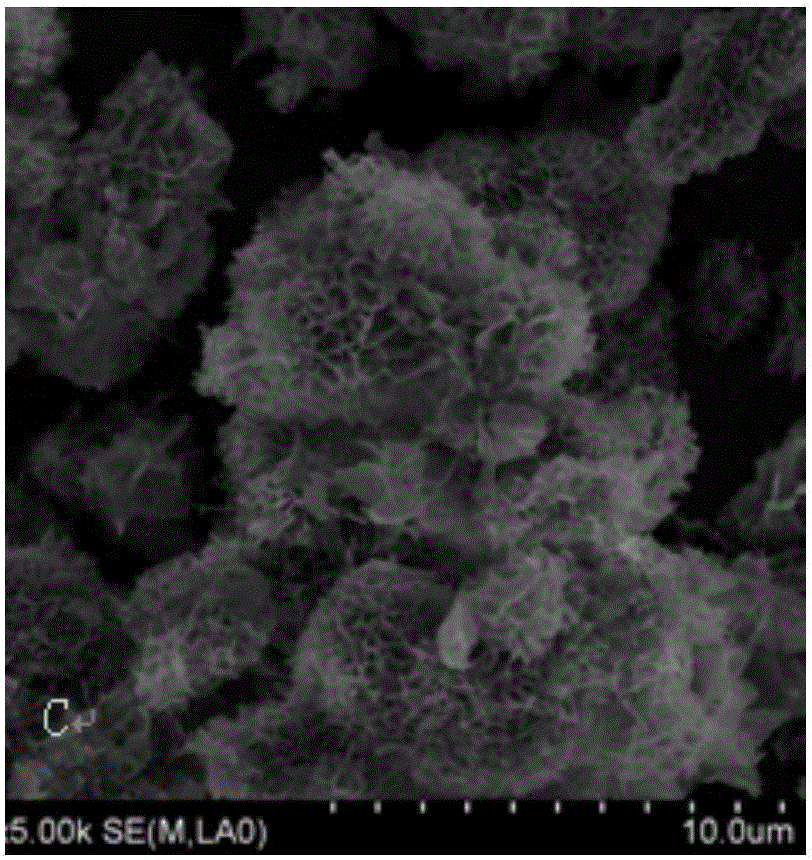

[0039] Add 0.9ml, 0.2 mol / L calcium chloride solution, reacted for 12 hours at 25°C, centrifuged at 12000rpm for 10min, and washed three times with distilled water to obtain α-acetolactate decarboxylase-calcium phosphate-proline endonuclease (PSEP-Ca 3 (PO 4 ) 2 -ALDC) immobilized enzyme, in the prepared immobilized enzyme, the content of immobilized enzyme per milligram of calcium phosphate loaded is 28.84mg, and its electron micrograph is as follows image 3 shown. It can be seen from the figure that at this initial enzyme concentration, the sheet structure is further loosened, forming a honeycomb shape, with a better nanoflower structure, and the specific surface area is further increased. At this time, the activities of the two enzymes that have been immobilized are basically the same as the activity of the free enzyme, and even higher than the activity of the free enzyme.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com