Method for preparing graphene material and cogenerating hydrogen

A graphene and hydrogen technology, applied in nanotechnology, electrolysis process, electrolysis components, etc., to achieve the effect of low cost, high output and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A method for preparing graphene material co-production hydrogen, comprising the following steps:

[0027] (1) flake graphite is pressed into sheets in a sheeting abrasive to make electrodes with a thickness of 2mm, the pressure is 15Mpa, and the pressurization time is 10min;

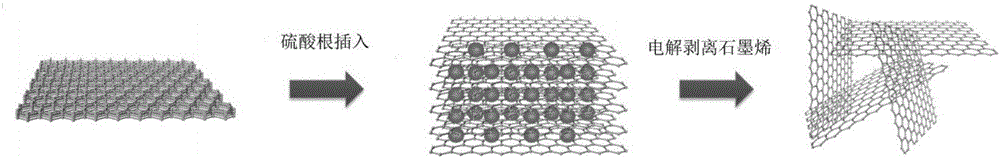

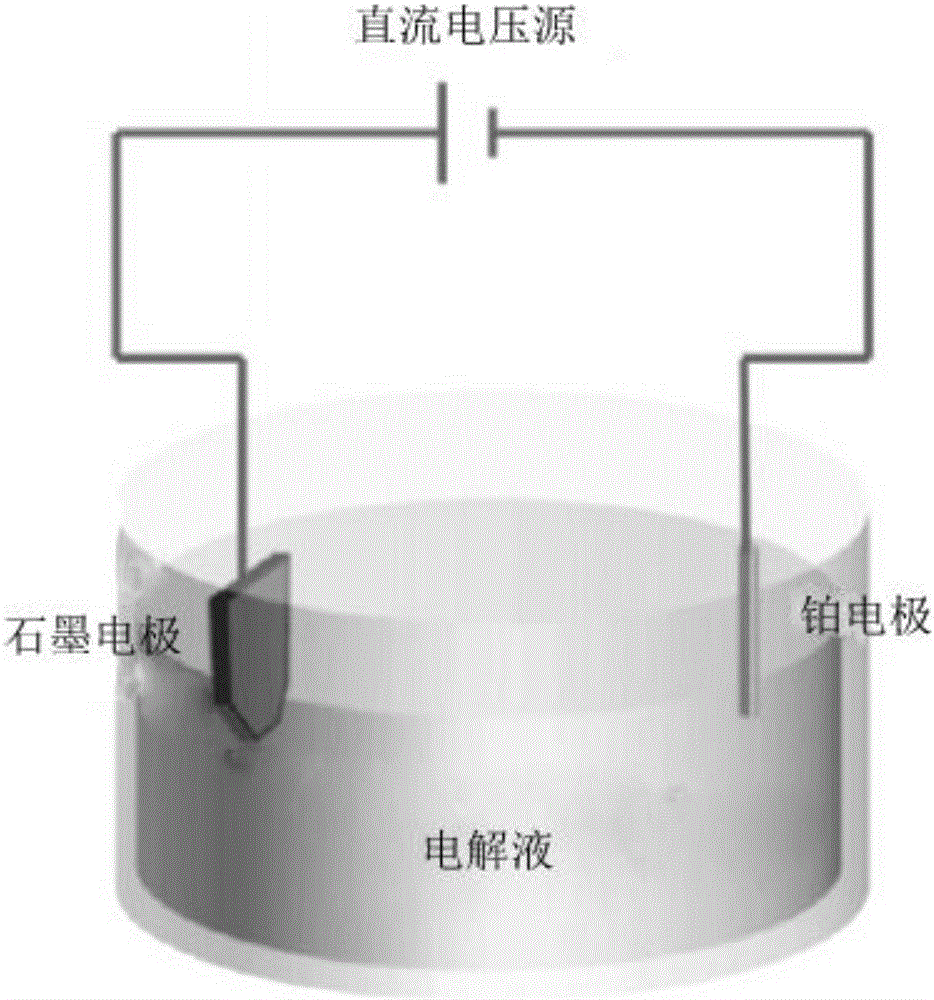

[0028] (2) Do positive pole with graphite electrode, platinum electrode with negative pole and electrolyze in electrolyte; Wherein electrolyte is the mixed solution of 98% concentrated sulfuric acid and deionized water, the pH=1~3 of mixed solution; During electrolysis, electrode distance 3cm, First add a voltage of 1V for 30min to make SO 4 2- Fully insert the graphite sheet, and then use 5V constant voltage electrolysis;

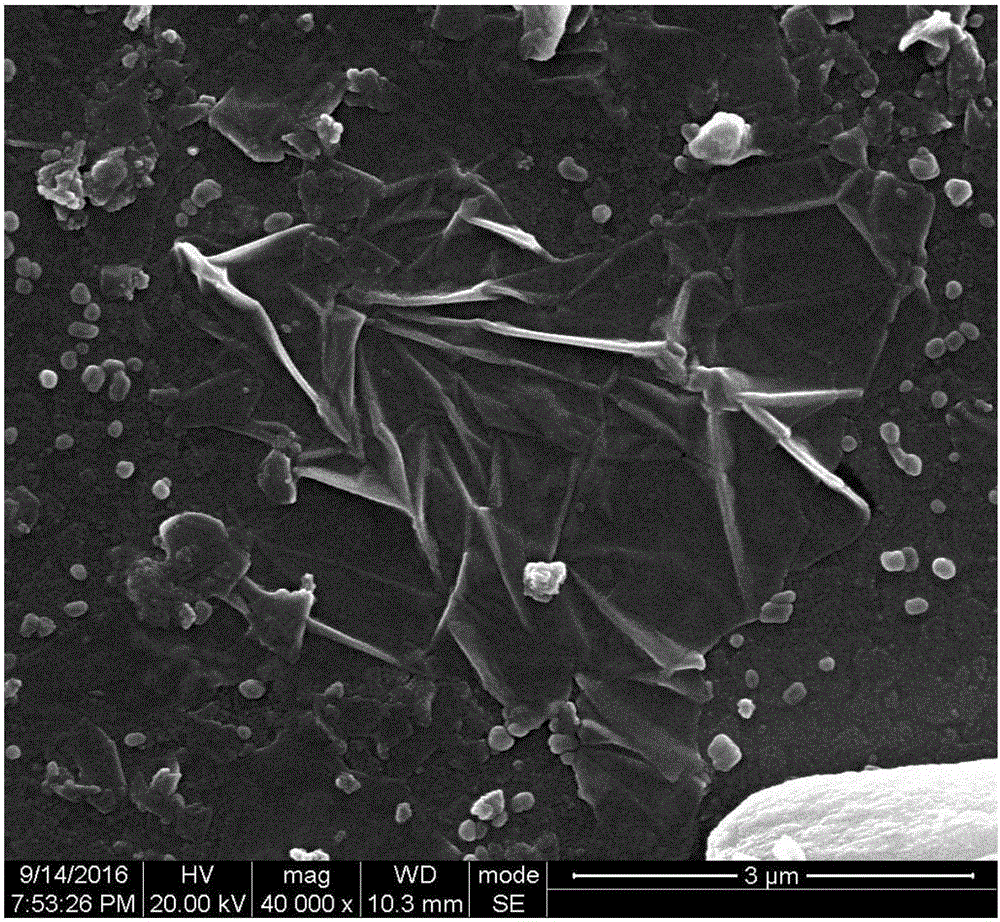

[0029] (3) During electrolysis, the platinum electrode generates hydrogen gas, the graphite on the graphite electrode peels off quickly, and the electrolyte is in a black and turbid state; use a filter membrane to filter the electrolyte and wash the residual SO with deionize...

Embodiment 2

[0033] A method for preparing graphene material co-production hydrogen, comprising the following steps:

[0034] (1) Expanded graphite is pressed into sheets in a sheeting abrasive to make electrodes with a thickness of 2mm, the pressure is 30Mpa, and the pressurization time is 15min;

[0035] (2) Do positive pole with graphite electrode and platinum electrode as negative pole and electrolyze in electrolyte; Wherein electrolyte is the mixed solution of 98% concentrated sulfuric acid and deionized water, the pH=1~3 of mixed solution; During electrolysis, the electrode spacing is 4cm, First add a voltage of 2V for 30min to make SO 4 2- Fully insert the graphite sheet, and then use 10V constant voltage electrolysis;

[0036] (3) During electrolysis, the platinum electrode generates hydrogen gas, the graphite on the graphite electrode peels off quickly, and the electrolyte is in a black and turbid state; use a filter membrane to filter the electrolyte and wash the residual SO wi...

Embodiment 3

[0040] A method for preparing graphene material co-production hydrogen, comprising the following steps:

[0041] (1) flake graphite is pressed into sheets in a sheeting abrasive to make electrodes with a thickness of 2mm, the pressure is 25Mpa, and the pressurization time is 20min;

[0042] (2) Do positive pole with graphite electrode and platinum electrode as negative pole and electrolyze in electrolyte; Wherein electrolyte is the mixed solution of 98% concentrated sulfuric acid and deionized water, the pH=1~3 of mixed solution; During electrolysis, electrode distance 2cm, First add a voltage of 2V for 30min to make SO 4 2- Fully insert the graphite sheet, and then use 6.5V constant voltage electrolysis;

[0043](3) During electrolysis, the platinum electrode generates hydrogen gas, the graphite on the graphite electrode peels off quickly, and the electrolyte is in a black and turbid state; use a filter membrane to filter the electrolyte and use deionized water to wash away...

PUM

| Property | Measurement | Unit |

|---|---|---|

| carrier mobility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com