Suspension electrolysis method for lead sulfate

A technology of lead sulfate and electrolyte, applied in the field of wet lead smelting, can solve the problems of unusable by-products, large consumption of reagents, crossover, etc., and achieve the effects of large-scale popularization and application, low material consumption and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

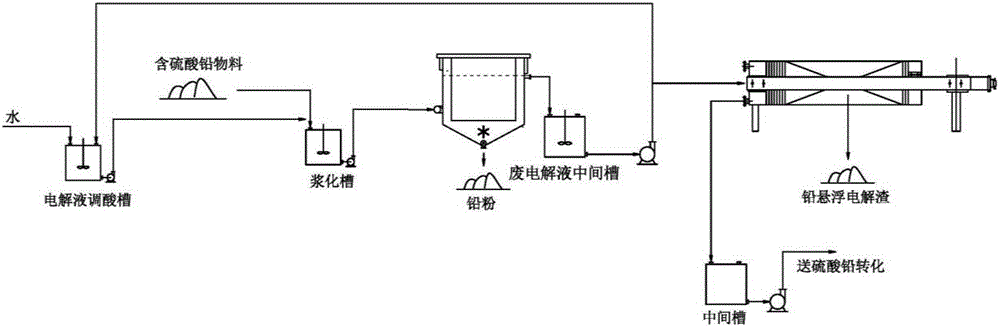

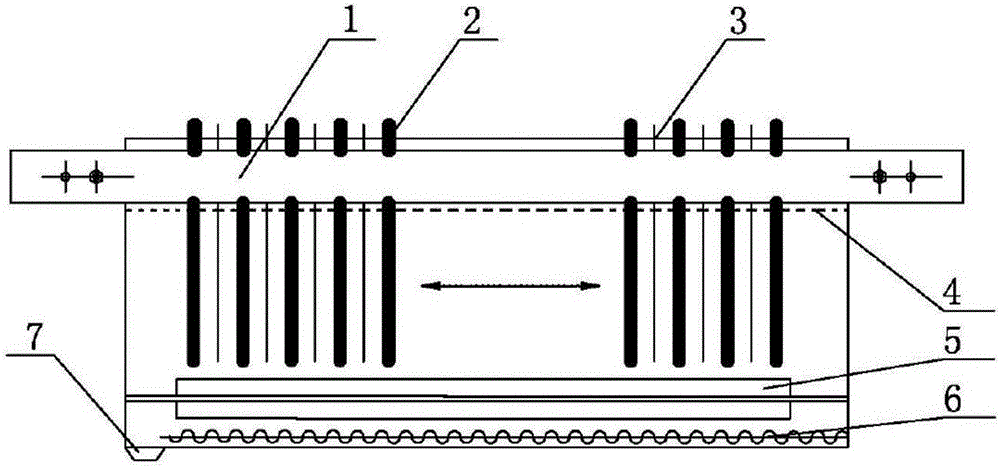

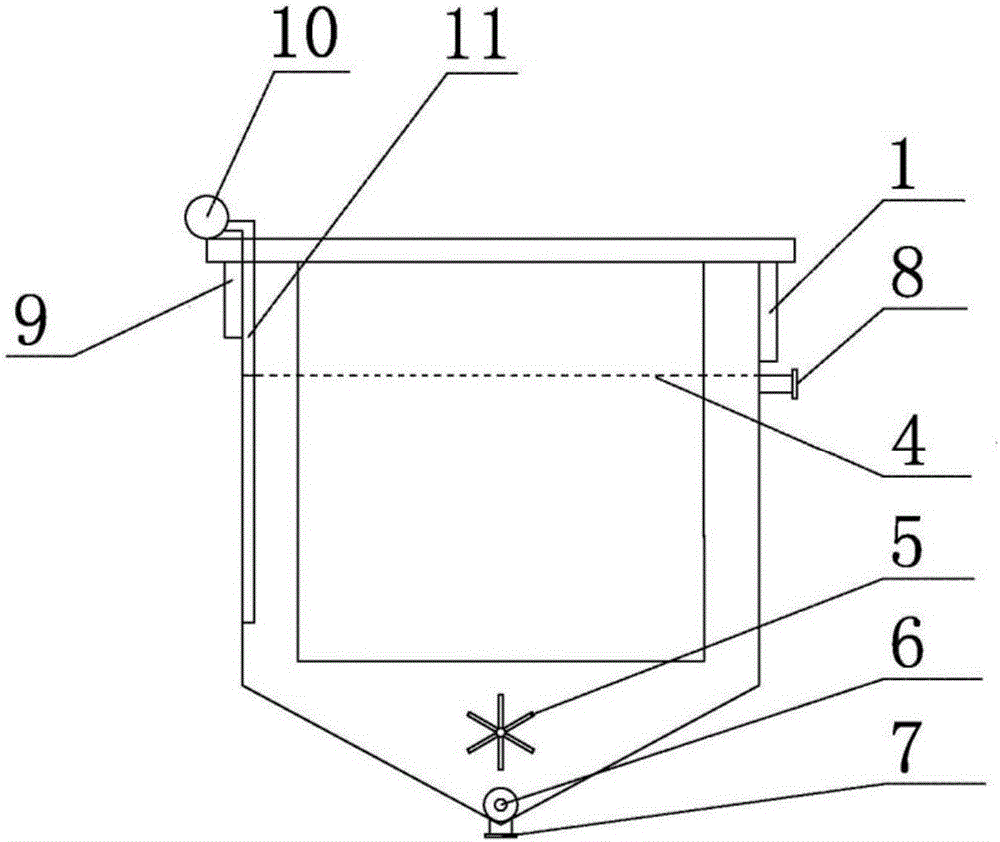

Method used

Image

Examples

Embodiment 1

[0034] In a kind of method of lead sulfate suspension electrolysis, with PbSO 4 90% lead-containing materials are used as raw materials, and lead sulfate slurry is obtained by slurrying waste electrolyte, wherein the solid concentration is 15%, and the H 2 SO 4 Concentration 120g / L; lead sulfate slurry in 1m 3 The speed of / h is continuously added to the suspension electrolyzer, and the cathode current density is 250A / m 2 , the lead sulfate particles are reduced and precipitated at the cathode to 113kg of lead powder, and the lead powder is washed, filtered and compacted to form rough lead; the anode produces sulfuric acid and oxygen, and the waste electrolyte contains H 2 SO 4 Up to 174g / L. Open 32% of the waste electrolyte, and add the same volume of deionized water to the remaining 68% of the waste electrolyte, and the concentration of sulfuric acid in the electrolyte is 118g / L; for SiO 2 , Fe 2 o 3 and a small amount of incompletely reacted PbSO 4 , filter, and t...

Embodiment 2

[0036] In a kind of method of lead sulfate suspension electrolysis, with PbSO 4 60% lead-containing materials are used as raw materials, and lead sulfate slurry is obtained by slurrying waste electrolyte, wherein the solid concentration is 20%, and the H 2 SO 4 Concentration 150g / L; lead sulfate slurry in 1m 3 The speed of / h is continuously added to the suspension electrolyzer, and the cathode current density is 230A / m 2 , the lead sulfate particles are reduced at the cathode to precipitate 95kg of lead powder, and the lead powder is washed, filtered and compacted to form rough lead; the anode produces sulfuric acid and oxygen, and the waste electrolyte contains H 2 SO 4 Up to 196g / L. About 24% of the waste electrolyte is opened, and the same volume of deionized water is added to the remaining 76% of the waste electrolyte. The concentration of sulfuric acid in the electrolyte is 149g / L; Mainly SiO 2 , Fe 2 o 3 and a small amount of incompletely reacted PbSO 4 , filt...

Embodiment 3

[0038] In a kind of method of lead sulfate suspension electrolysis, with PbSO 4 80% lead-containing materials are used as raw materials, and lead sulfate slurry is obtained by slurrying waste electrolyte, wherein the solid concentration is 18%, and the H 2 SO 4 Concentration 140g / L; lead sulfate slurry in 1m 3 The speed of / h is continuously added to the suspension electrolyzer, and the cathode current density is 250A / m 2 120kg of lead powder is precipitated by reduction of lead sulfate particles at the cathode, and the lead powder is washed, filtered and compacted to form rough lead; the anode produces sulfuric acid and oxygen, and the waste electrolyte contains H 2 SO 4 Up to 197g / L. About 30% of the waste electrolyte is opened, and the same volume of deionized water is added to the remaining 70% of the waste electrolyte. The concentration of sulfuric acid in the electrolyte is 142g / L; Mainly SiO 2 , Fe 2 o 3 and a small amount of incompletely reacted PbSO 4 , filt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com