Insulation cooling fin for notebook computer

A notebook computer, heat sink technology, applied in electrical digital data processing, instruments, digital data processing components and other directions, can solve the problems of large size, noise, inconvenience to carry, etc., to achieve small size, thin appearance, reliable heat dissipation effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

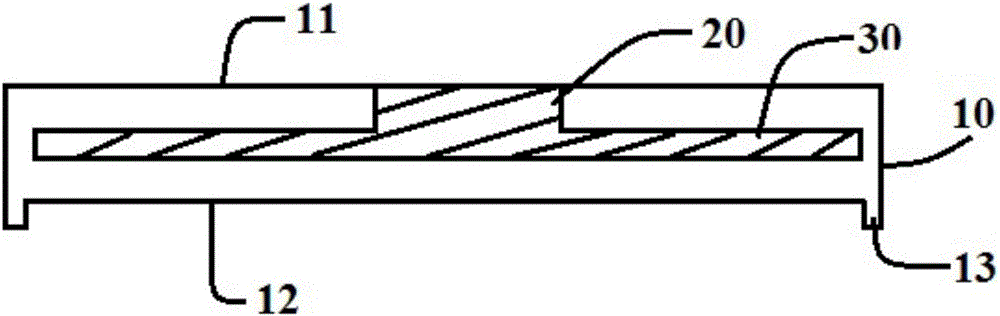

[0021] The heat dissipation module and the soaking sheet are integrally formed by copper. The surface roughness of the copper is less than 0.5 μm. Firstly, the copper is washed with alkali to remove oil and pickled to remove residual oxides. Then 50g / L of H 2 SO 4 and 10g / L of hydrogen peroxide in a mixed aqueous solution at a temperature of 0 to 5°C for 5 minutes, followed by water washing. After washing with water, carry out oxidation treatment under the condition that the temperature of the oxidation treatment solution is 20°C, the treatment time is 1 minute, the composition of the oxidation treatment solution is 100g / L hydrogen peroxide, 12.0g / L 3-aminopropyltrimethoxy Silane, 20g / L of citric acid, 20g / L of aminonaphthalene disulfonic acid, and the balance of water. After oxidation treatment, after washing with water, a fine concave-convex structure can be observed under the SEM field of view, and the heat dissipation module and soaking sheet after treatment are reddish ...

Embodiment 2

[0023] The heat dissipation module and the soaking sheet are integrally formed by copper. The surface roughness of the copper is less than 0.5 μm. Firstly, the copper is washed with alkali to remove oil and pickled to remove residual oxides. Then 50g / L of H 2 SO 4 and 10g / L of hydrogen peroxide in a mixed aqueous solution at a temperature of 0 to 5°C for 5 minutes, followed by water washing. After washing with water, carry out oxidation treatment under the condition that the temperature of the oxidation treatment solution is 20°C, the treatment time is 5 minutes, the composition of the oxidation treatment solution is 50g / L hydrogen peroxide, 8.0g / L 3-aminopropyl trimethoxy Silane, 20g / L of citric acid, 10g / L of β-aminoethanesulfonic acid, and the balance of water. After oxidation treatment, after washing with water, a fine concave-convex structure can be observed under the SEM field of view, and the heat dissipation module and soaking sheet after treatment are reddish brown....

Embodiment 3

[0025] The heat dissipation module and the soaking sheet are integrally formed by copper. The surface roughness of the copper is less than 0.5 μm. Firstly, the copper is washed with alkali to remove oil and pickled to remove residual oxides. Then 50g / L of H 2 SO 4 and 10g / L of hydrogen peroxide in a mixed aqueous solution at a temperature of 0 to 5°C for 5 minutes, followed by water washing. After washing with water, under the condition that the oxidation treatment solution temperature is 25 ℃, carry out oxidation treatment, treatment time is 3 minutes, and the composition of oxidation treatment solution is the hydrogen peroxide of 80g / L, the N-2-(aminoethyl group of 10.0g / L )-3-aminopropylmethyldiethoxysilane, the citric acid of 25g / L, the β-taurine of 18g / L, and the water of remainder. After oxidation treatment, after washing with water, a fine concave-convex structure can be observed under the SEM field of view, and the heat dissipation module and soaking sheet after trea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com