A kind of manufacturing method of sandwich structure carbon/silicon carbide aircraft brake material

A sandwich structure and brake material technology, applied in chemical instruments and methods, layered products, mechanical equipment, etc., can solve problems affecting the stability of material friction performance and uneven phase distribution, and achieve good repeatability and simple process Effect

Inactive Publication Date: 2012-01-18

NORTHWESTERN POLYTECHNICAL UNIV

View PDF0 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

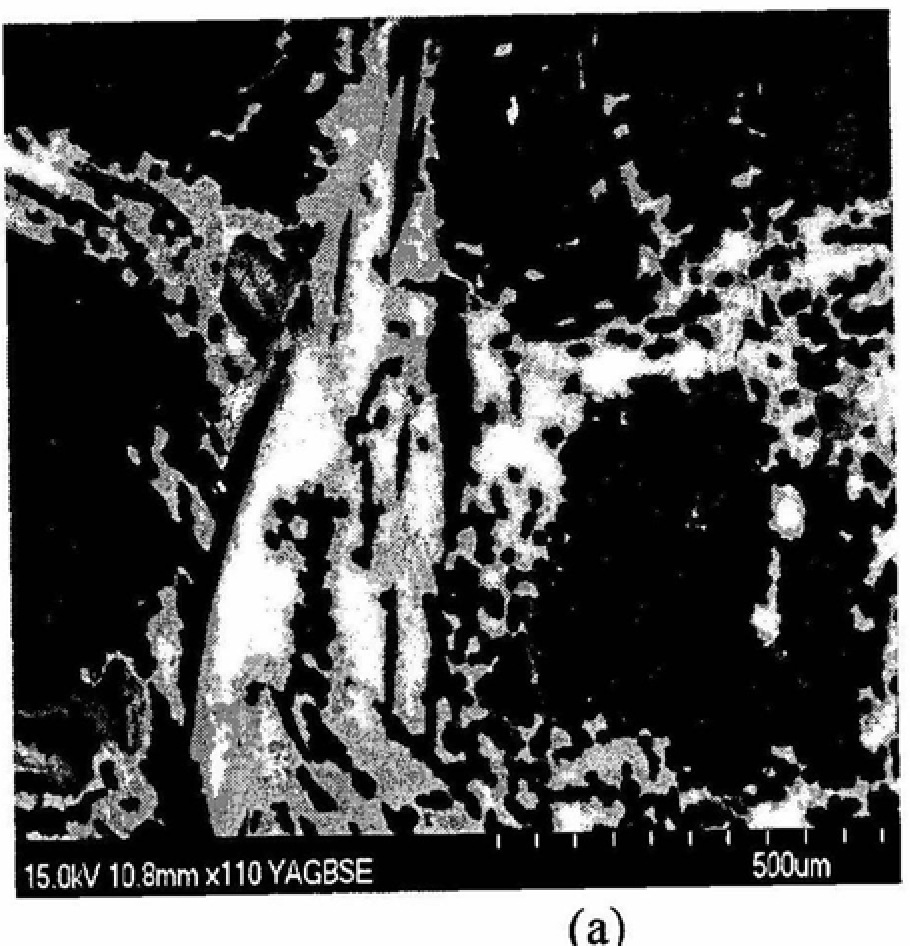

Uneven phase distribution will affect the stability of the friction properties of the material; and the materials prepared by the RMI process inevitably

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Login to View More

Abstract

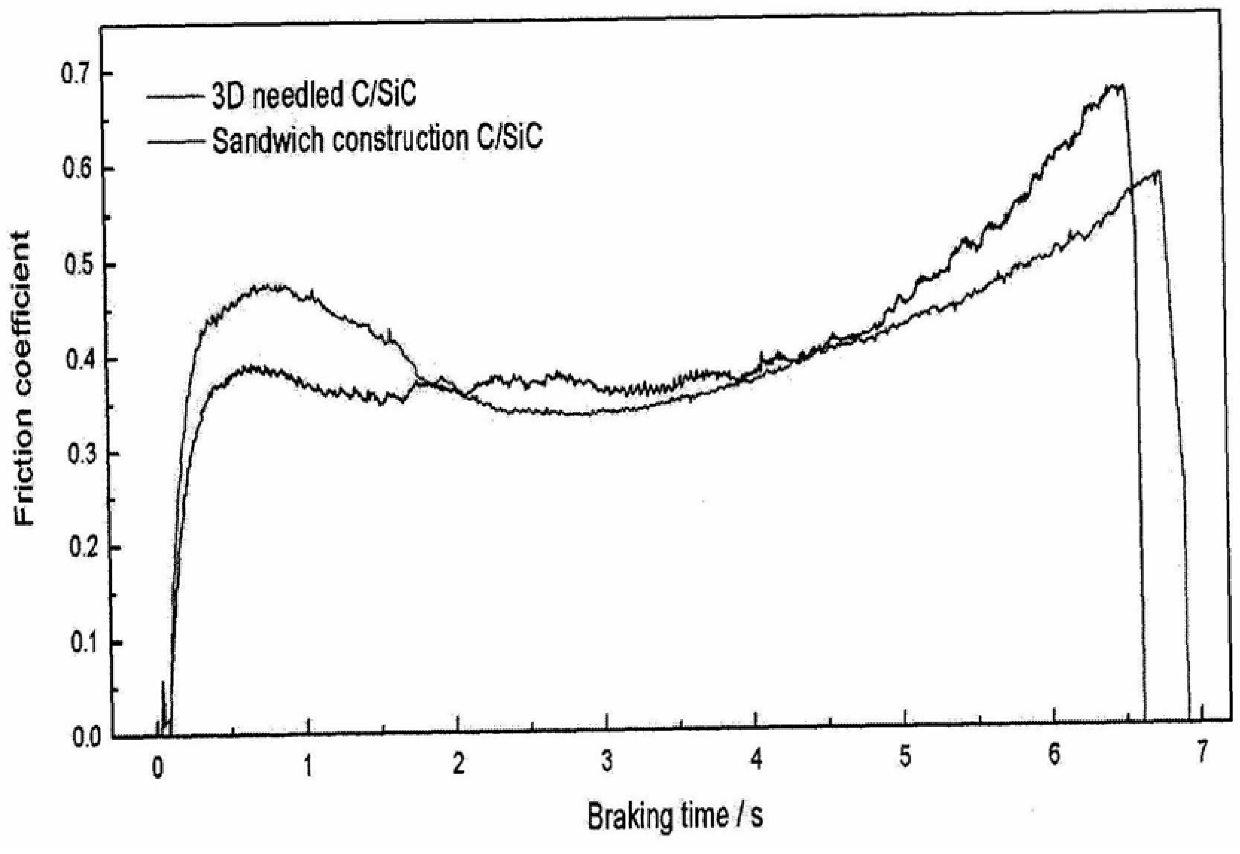

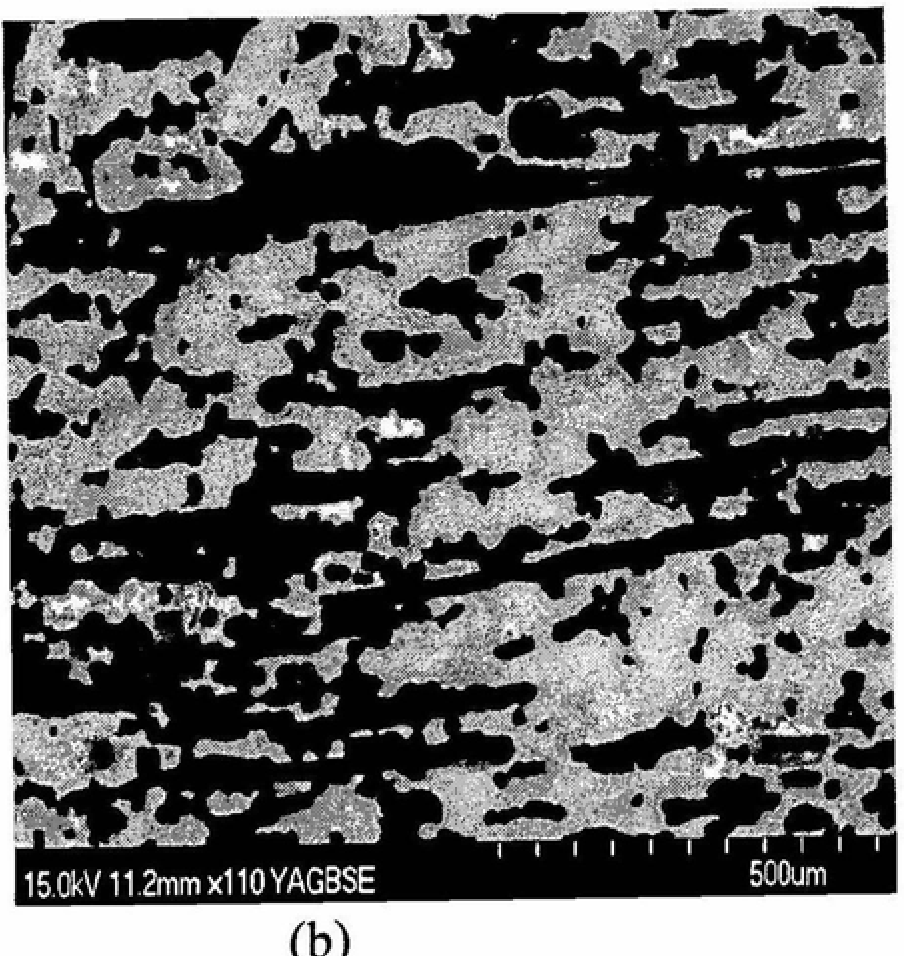

The invention relates to a method for manufacturing a carbon / silicon carbide aircraft brake material with a sandwich structure. A porous sandwich structure carbon / carbon composite material and a porous sandwich structure carbon / carbon composite material high-temperature graphite are prepared by preparing a sandwich structure carbon fiber prefabricated body and a chemical vapor deposition method. Chemical treatment, preparation of water-based graphite powder slurry, water-based graphite powder slurry impregnated porous sandwich structure carbon / carbon composite material, impregnated graphite powder porous sandwich structure carbon / carbon composite material for reaction melt infiltration treatment. The invention effectively solves the problem of residual Si and its agglomeration in the traditional RMI process, realizes the uniform distribution of the material phase of the friction function layer, and the reasonable matching of material structure and function. The friction performance of the manufactured brake disc is high and stable, and the wear rate Small, friction performance is not sensitive to environmental humidity and temperature, and has excellent mechanical properties, can meet the requirements of aircraft brake materials, and has simple process, strong process controllability, good repeatability and low cost.

Description

A kind of manufacturing method of sandwich structure carbon / silicon carbide aircraft brake material 1. Technical field The present invention relates to a kind of manufacture method of carbon / silicon carbide brake material, particularly relate to a kind of sandwich structure carbon / silicon carbide A method of manufacturing a silicon carbide aircraft brake material. 2. Background technology Powder metallurgy and carbon / carbon brake material are main aircraft brake material at present, and carbon / silicon carbide brake material is Following powder metallurgy and carbon / carbon brake materials, a new generation of brake materials developed. Carbon / Silicon Carbide Brake Material No However, it overcomes the shortcomings of powder metallurgy brake materials such as high density and high temperature and easy bonding, and overcomes the carbon / carbon brake material that is easy to oxidize. There are many disadvantages, such as serious attenuation of wet friction performance, l...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): F16D69/00B32B5/14B32B18/00C04B35/80

Inventor 范尚武张立同成来飞杨尚杰

Owner NORTHWESTERN POLYTECHNICAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com