Herbicide used for paddy rice and application and preparation method thereof

A technology for paddy field and herbicide, which is applied in the directions of herbicides and algaecides, botanical equipment and methods, applications, etc., can solve the problems of difficult application of rice herbicides and high labor costs, and achieves improved herbicidal efficacy and convenient use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

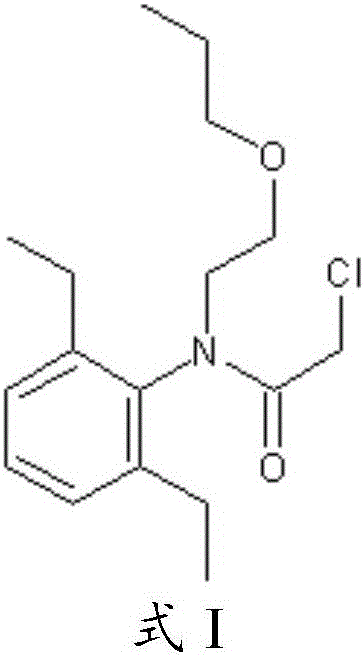

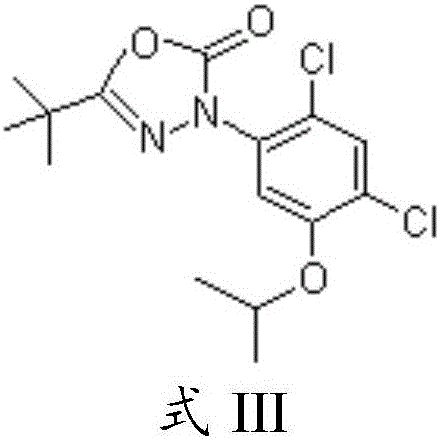

[0055] The active ingredient of the composition of this example is composed of two components, A and B, A is pretilachlor, B is propargyl oxadiazone, and the content of the herbicide active ingredient is 25.5%.

[0056] The composition and weight percentage of the composition are as follows: 25.0% of pretilachlor, 0.5% of propargyl clomazone, 5.0% of No. 150 solvent naphtha, 5.0% of calcium dodecylbenzenesulfonate, tristyrylphenol polyoxygen Vinyl ether 5.0%, polyvinyl alcohol 59.5%.

[0057] The steps and conditions of its preparation method are as follows:

[0058] (1) According to the ratio of raw materials, add components A, B and solvent oil into the stirring tank and stir for 30 minutes, and heat during the stirring process;

[0059] (2) After dissolving evenly, add emulsifier and continue to stir for 20 minutes;

[0060] (3) Add polyvinyl alcohol, heat to 90°C while stirring, and keep warm for 20 minutes.

[0061] (4) Pour the material into a metal container and cool...

Embodiment 2

[0066] The active ingredient of the composition of this example is composed of two components, A and B, A is pretilachlor, and B is saponin, and the active ingredient content of the herbicide composition is 12.75%.

[0067] The composition and weight percentages of the composition are as follows: 0.25% pretilachlor, 12.5% saponin, 5.0% No. 150 solvent naphtha, 5.0% calcium dodecylbenzenesulfonate, tristyrylphenol polyoxyethylene ether 5.0%, gum 72.25%.

[0068] The steps and conditions of its preparation method are as follows:

[0069] (1) According to the ratio of raw materials, add components A, B and solvent oil into the stirring tank and stir for 30 minutes, and heat during the stirring process;

[0070] (2) After dissolving evenly, add emulsifier and continue to stir for 20 minutes;

[0071] (3) Add gum, heat to 90°C while stirring, and keep warm for 20 minutes;

[0072] (4) Pour the material into a metal container and cool down naturally. That is, the target produc...

Embodiment 3

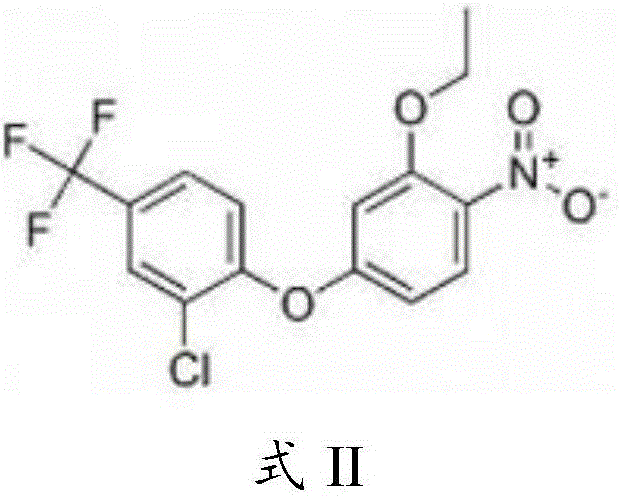

[0077] The active ingredient of the composition of this example consists of two components, A and B, A is pretilachlor, B is oxyfluorfen and oxadiazone, and the active ingredient content of the herbicide composition is 17.0%.

[0078] The components and weight percentages of the composition are as follows: pretilachlor 8.0%, oxyfluorfen 5.0%, oxadiazone 4.0%, saponin 150 solvent oil 8.0%, calcium dodecylbenzenesulfonate 5.0%, tristyrylphenol polyoxyethylene ether 5.0%, polyethylene glycol 65.0%.

[0079] The steps and conditions of its preparation method are as follows:

[0080] (1) According to the ratio of raw materials, add components A, B and solvent oil into the stirring tank and stir for 30 minutes, and heat during the stirring process;

[0081] (2) After dissolving evenly, add emulsifier and continue to stir for 20 minutes;

[0082] (3) Add polyethylene glycol, heat to 90°C while stirring, and keep warm for 20 minutes;

[0083] (4) Pour the material into a metal cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com