Soft capsule and preparation method thereof

A technology of soft capsules and capsule skins, which is applied in capsule delivery, pharmaceutical formulations, medical preparations of non-active ingredients, etc. It can solve the problems of easy shell cracking, capsule hardening, soft capsule hardening, etc., and reach the disintegration time limit Good effect of stability, maintaining elasticity and hardness, uniformity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

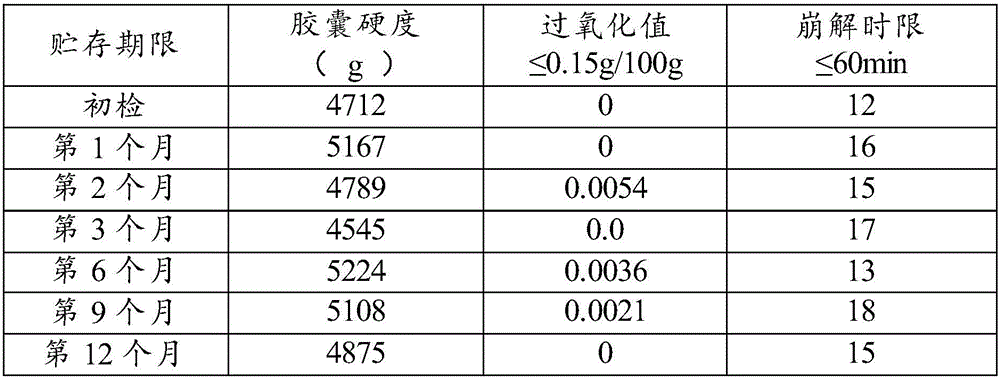

[0036] Preparation and detection of embodiment 1 soft capsule

[0037] 1, the formula of this embodiment soybean lecithin soft capsule is as follows:

[0038] The content of table 1 embodiment 1 soft capsule and the formula of rubber

[0039] Contents (10% glycerol, added in 2:3:5) rubber Soy Lecithin: Soybean Oil: Glycerin = 89:1:10 Glycerin: Purified Water: Gelatin = 1:2:2

[0040] 2. The preparation process of the soft capsule is as follows (content glycerol is added at 2:3:5):

[0041] (1) The capsule skin is prepared in a chemical glue tank;

[0042] (2) Preparation of soft capsule contents:

[0043] 1) When the pressure in the batching tank is -0.05MPa, the temperature is 40°C, and the stirring speed is set to 65 rpm, add the soybean oil of the recipe amount into the batching tank, and add 20% of the recipe amount of glycerin while stirring. The stirring time was 5 minutes.

[0044] 2) After the stirring time is reached, open the lid of the bat...

Embodiment 2

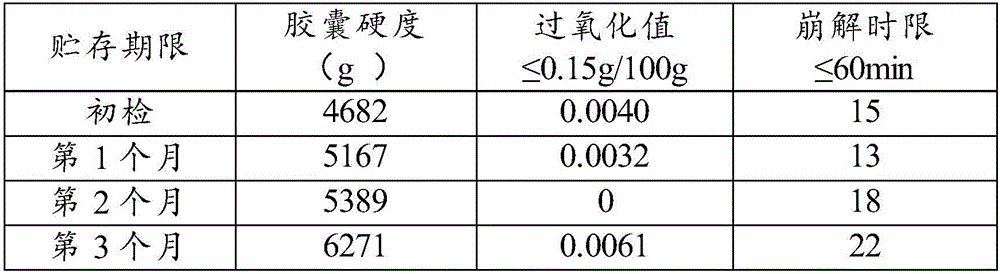

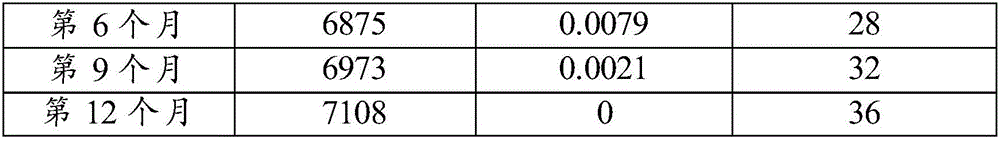

[0056] Preparation and detection of embodiment 2 soft capsules

[0057] 1, the formula of this embodiment soybean lecithin soft capsule is as follows:

[0058]The content of table 3 embodiment 2 soft capsules and the formula of rubber

[0059] Contents (glycerol 4%, added 2:3:5) rubber Soy Lecithin: Soybean Oil: Glycerin = 95:1:4 Glycerin: Purified Water: Gelatin = 1:2:2

[0060] 2. The preparation process of the soft capsule is as follows (content glycerol is added at 2:3:5):

[0061] (1) The capsule skin is prepared in a chemical glue tank;

[0062] (2) Preparation of soft capsule contents:

[0063] 1) When the pressure in the batching tank is -0.05MPa, the temperature is 40°C, and the stirring speed is set to 65 rpm, add the soybean oil of the recipe amount into the batching tank, and add 20% of the recipe amount of glycerin while stirring. The stirring time was 5 minutes.

[0064] 2) After the stirring time is reached, open the lid of the batchi...

Embodiment 3

[0077] Preparation and detection of embodiment 3 soft capsules

[0078] 1, the formula of this embodiment soybean lecithin soft capsule is as follows:

[0079] The content of table 5 embodiment 3 soft capsules and the prescription of rubber

[0080] Contents (15% glycerol, added 2:3:5) rubber Soy Lecithin: Soybean Oil: Glycerin = 84:1:15 Glycerin: Purified Water: Gelatin = 1:2:2

[0081] 2. The preparation process of the soft capsule is as follows (content glycerol is added at 2:3:5):

[0082] (1) The capsule skin is prepared in a chemical glue tank;

[0083] (2) Preparation of soft capsule contents:

[0084] 1) When the pressure in the batching tank is -0.05MPa, the temperature is 40°C, and the stirring speed is set to 65 rpm, add the soybean oil of the recipe amount into the batching tank, and add 20% of the recipe amount of glycerin while stirring. The stirring time was 5 minutes.

[0085] 2) After the stirring time is reached, open the lid of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com