Bimetallic strip feeding system for heat protector and automatic welding machine applying same

A technology of automatic welding machine and bimetal sheet, which is applied in welding equipment, auxiliary welding equipment, metal processing equipment, etc., can solve the problems of increasing production cost, increasing operator's workload, reducing production efficiency, etc., so as to improve production efficiency, The feeding method is simple and practical, realizing the effect of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

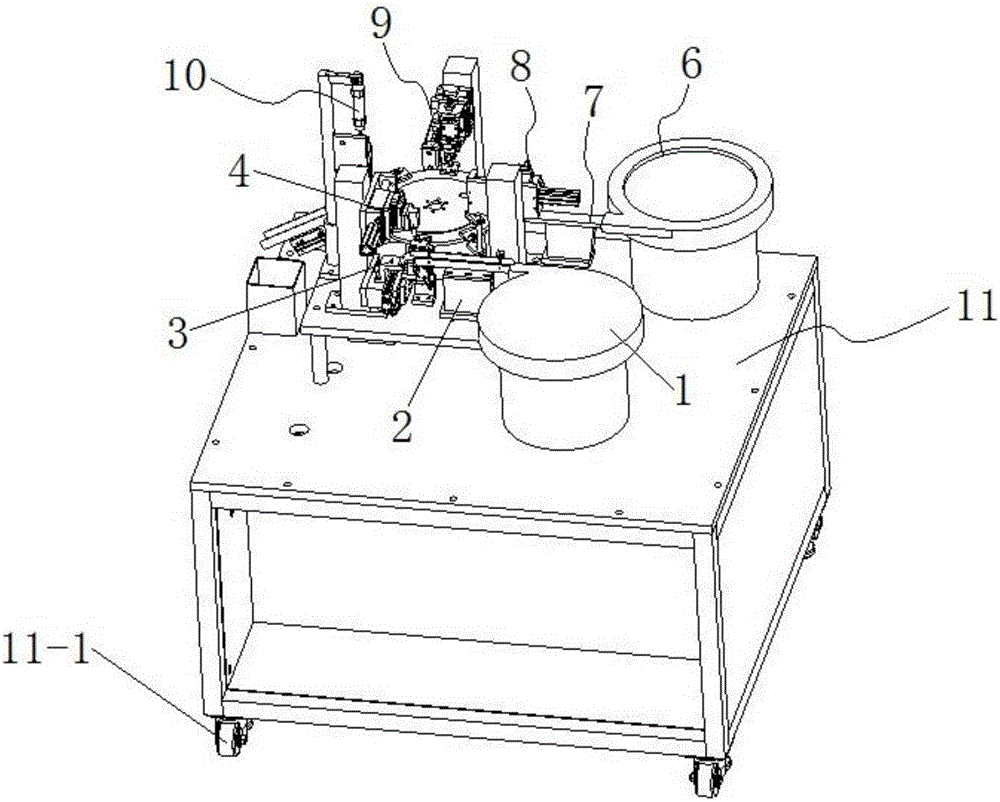

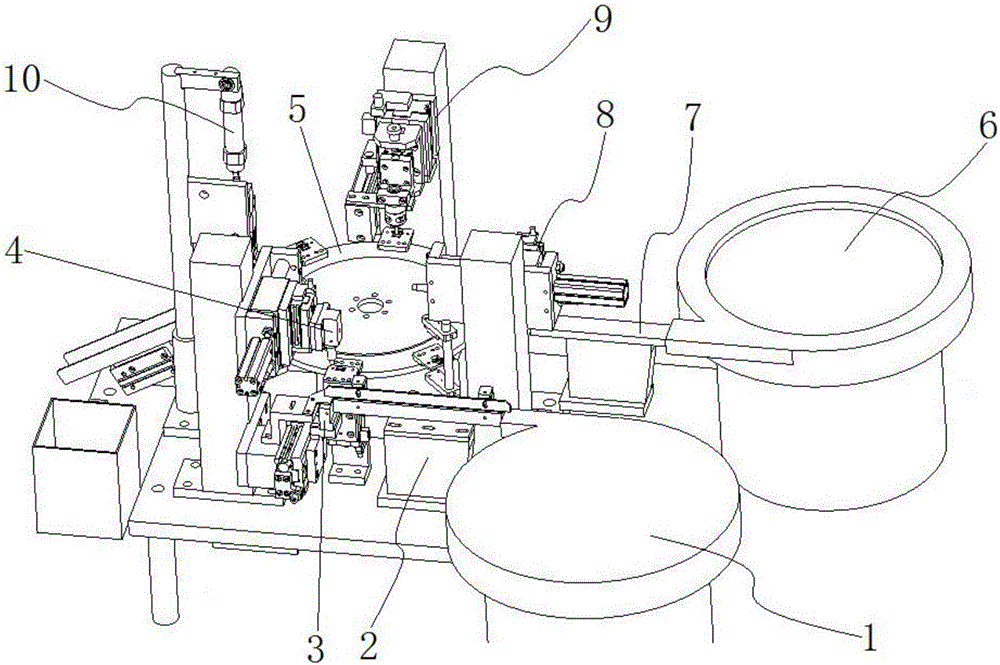

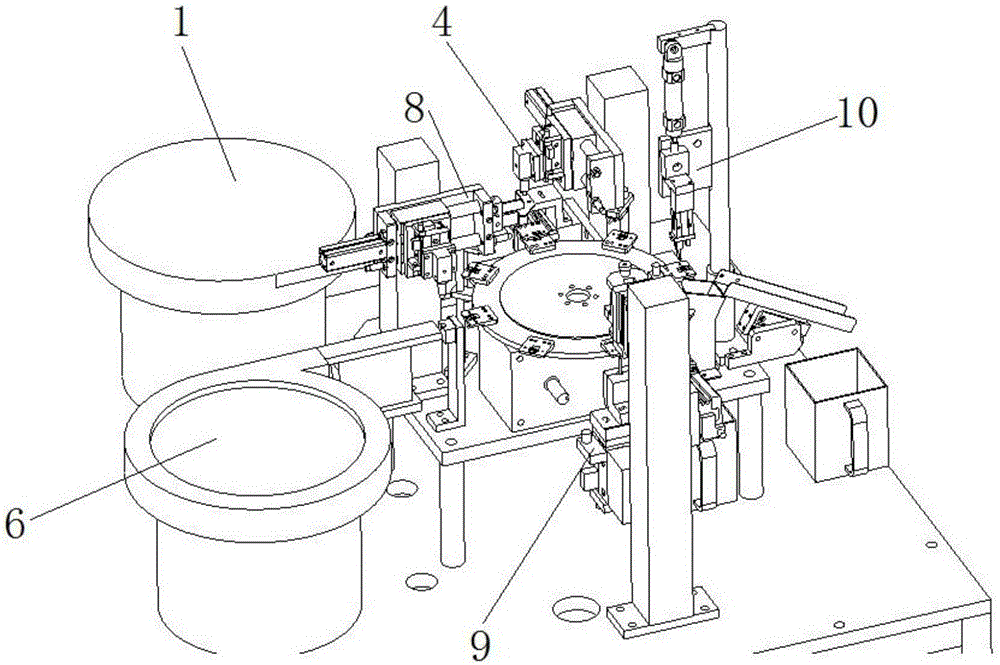

[0063] combine Figure 11 As shown, a bimetal feeding system for thermal protectors in this embodiment includes a bimetal feeding device 1, a bimetal feeding device 2 and a bimetal feeding device 3 connected in sequence. The metal sheet feeding system also includes a bimetal sheet feeding device 4 for moving the bimetal sheet on the bimetal sheet feeding termination station to the processing platform 5 .

[0064] Wherein, the bimetal sheet feeding device 1 of the present embodiment adopts the vibrating plate automatic feeding machine 1-1, and the vibrating plate automatic feeding machine 1-1 is provided with for automatically feeding the bimetallic sheets with closer intervals from the vibrating plate The material shifting mechanism removed from the feeding path of machine 1-1 can effectively control the spacing of the bimetallic sheets when feeding and avoid stacking between the bimetallic sheets. Preferably, the feeding mechanism is set on the vibrating plate for automatic f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com