Kiln method for producing phosphoric acid and light aggregate

A lightweight aggregate and phosphoric acid technology, applied in the direction of phosphoric acid, phosphorus oxyacid, etc., to achieve the effects of reducing damage, obvious economic and social benefits, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

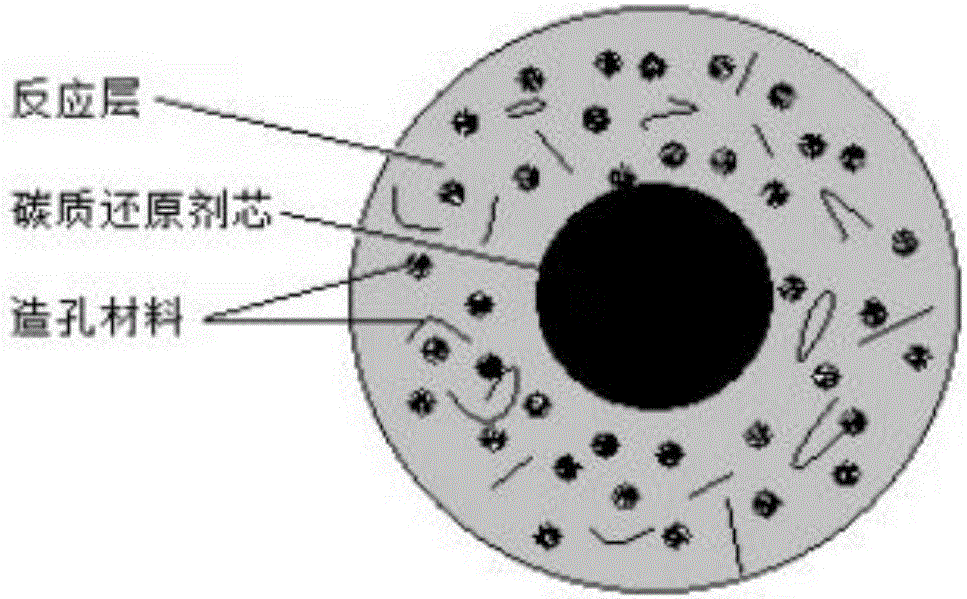

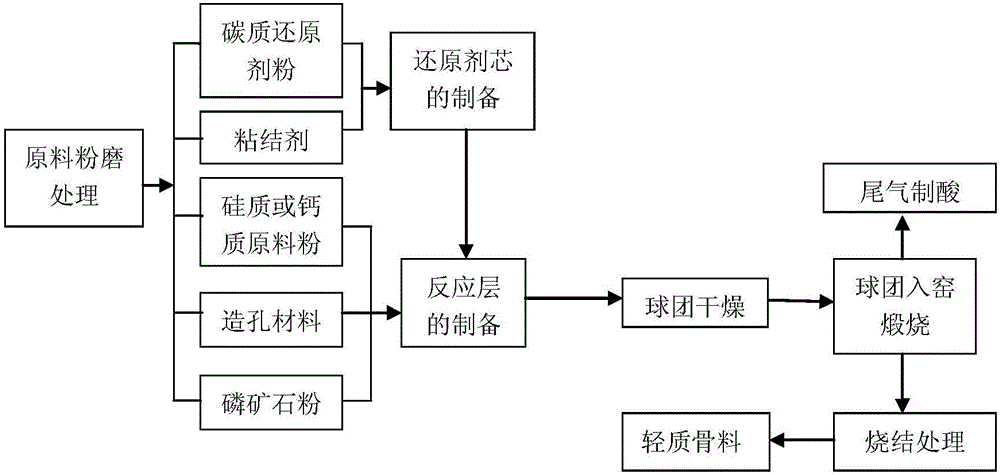

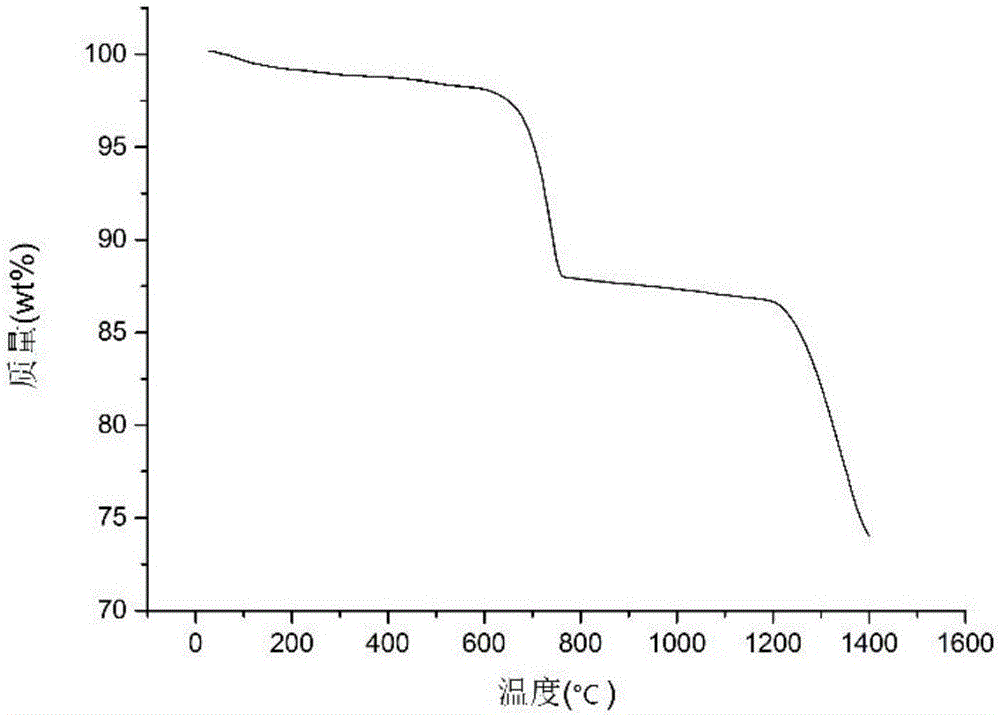

[0062] A method for kiln-process phosphoric acid co-production of lightweight aggregate, comprising the following steps:

[0063] a. Raw material pretreatment: crush the phosphate rock and put it into the grinding mill to make the particle size D 50 Phosphate rock powder ≤25μm; the calcium raw material and carbonaceous reducing agent are put into the mill for grinding, and the particle size is D 50 Calcium raw material powder ≤60μm, and carbonaceous reducing agent powder; the pore-forming material is crushed to make a particle size of D 50 Pore-forming material powder ≤80μm;

[0064] The calcium raw material is limestone powder or quicklime;

[0065] b. Ingredients: take raw carbonaceous reducing agent powder, binder, phosphate rock powder, calcareous raw material powder, and pore-forming material powder, and set aside;

[0066] The amount of the carbonaceous reductant powder is measured by the effective carbon (C) in the carbonaceous reductant powder, and the consumption o...

Embodiment 2

[0087] A method for kiln-process phosphoric acid co-production of lightweight aggregate, comprising the following steps:

[0088] a. Raw material pretreatment: crush the phosphate rock and put it into the grinding mill to make the particle size D 50 Phosphate rock powder ≤25μm; the calcium raw material and carbonaceous reducing agent are put into the mill for grinding, and the particle size is D 50 Calcium raw material powder ≤60μm, and carbonaceous reducing agent powder; the pore-forming material is crushed to make a particle size of D 50 Pore-forming material powder ≤80μm;

[0089] The calcium raw material is limestone powder or quicklime;

[0090] b. Ingredients: take raw carbonaceous reducing agent powder, binder, phosphate rock powder, calcareous raw material powder, and pore-forming material powder, and set aside;

[0091] The amount of the carbonaceous reductant powder is measured by the effective carbon (C) in the carbonaceous reductant powder, and the consumption o...

Embodiment 3

[0111] A method for kiln-process phosphoric acid co-production of lightweight aggregate, comprising the following steps:

[0112] a. Raw material pretreatment: crush the phosphate rock and put it into the grinding mill to make the particle size D 50 Phosphate rock powder ≤25μm; the calcium raw material and carbonaceous reducing agent are put into the mill for grinding, and the particle size is D 50 Calcium raw material powder ≤60μm, and carbonaceous reducing agent powder; the pore-forming material is crushed to make a particle size of D 50 Pore-forming material powder ≤80μm;

[0113] The calcium raw material is limestone powder or quicklime;

[0114] b. Ingredients: take raw carbonaceous reducing agent powder, binder, phosphate rock powder, calcareous raw material powder, and pore-forming material powder, and set aside;

[0115] The amount of the carbonaceous reductant powder is measured by the effective carbon (C) in the carbonaceous reductant powder, and the consumption o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com