Washing method of crude adipic acid slurry in adipic acid production process

A production process and washing method technology, applied in the separation/purification of carboxylic acid compounds, organic chemistry, etc., can solve problems such as viscosity drop, unsatisfactory, and high end-breakage rate, and achieve reduced nitrate content, reduced emissions, Realize the effect of green production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

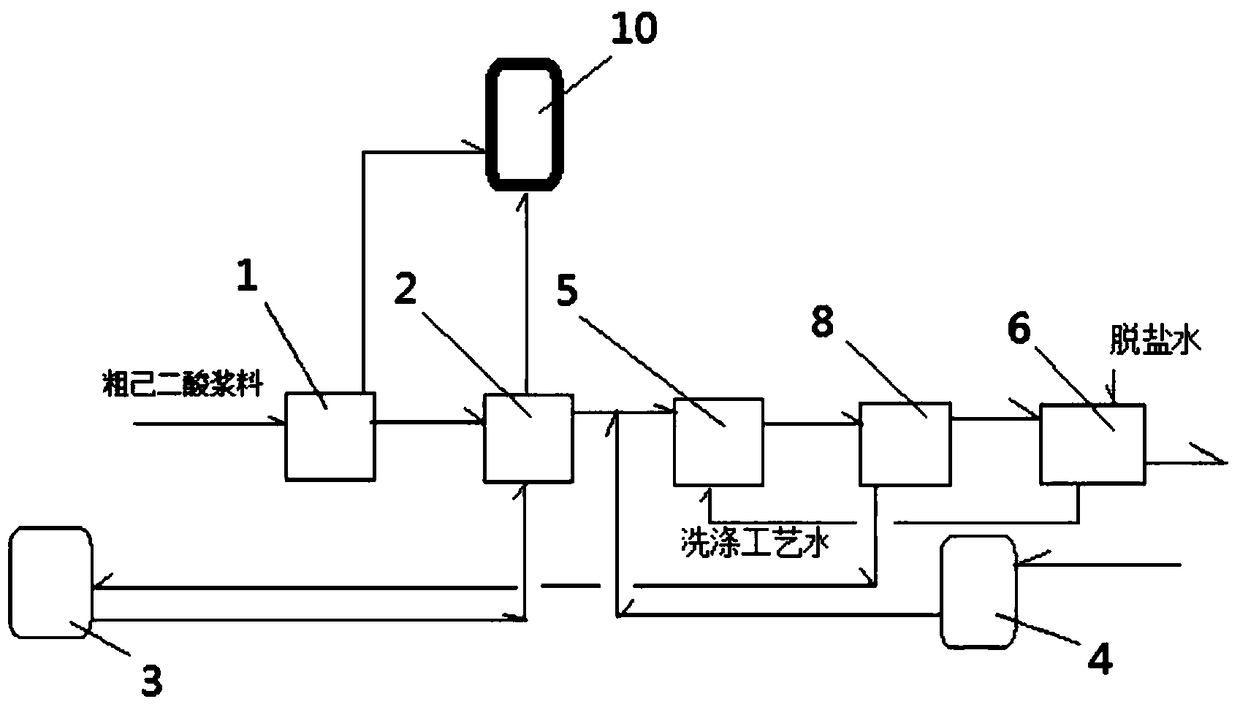

[0036] use figure 1 The process flow for the washing of the crude adipic acid slurry from the crude acid crystallization process.

[0037] (1) Send the crude adipic acid slurry from the crude acid crystallization process into the crude adipic acid thickener 1 to obtain thickened adipic acid slurry with a weight solid content of 35%;

[0038] In described thick adipic acid slurry, contain the component of following percentage by weight:

[0039] Adipic acid 34%, nitrate balance 19%, dibasic acid 8%, water 37%.

[0040] (2) Then the thickened adipic acid slurry obtained is sent into the crude acid centrifuge 2, and the original process water from the original process water tank 3 is used to 3 / h flow for washing, and liquid-solid separation to obtain wet adipic acid;

[0041] The weight ratio of thickened adipic acid slurry to former process water is:

[0042] Thickened adipic acid slurry: original process water = 1:0.8;

[0043] The washing water discharged from the crude ...

Embodiment 2

[0052] use figure 1 The process flow for the washing of the crude adipic acid slurry from the crude acid crystallization process.

[0053] (1) Send the crude adipic acid slurry from the crude acid crystallization process into the crude adipic acid thickener 1 to obtain thickened adipic acid slurry with a weight solid content of 45%;

[0054]In described thick adipic acid slurry, contain the component of following percentage by weight:

[0055] Adipic acid 37%, nitrate balance 14%, dibasic acid 7%, water 40%.

[0056] (2) Then the thickened adipic acid slurry obtained is sent into the crude acid centrifuge 2, and the original process water from the original process water tank 3 is used to 3 / h flow for washing, and liquid-solid separation to obtain wet adipic acid;

[0057] The weight ratio of thickened adipic acid slurry to former process water is:

[0058] Thickened adipic acid slurry: original process water = 1:1.2;

[0059] The washing water discharged from the crude a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com