Composite material ground roller shaft core

A composite material and ground roller technology, applied in the shaft core field, can solve problems affecting product quality and production volume, high maintenance costs, and short service life, so as to improve product quality and production volume, reduce manufacturing and maintenance costs, and reduce manufacturing costs. Process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

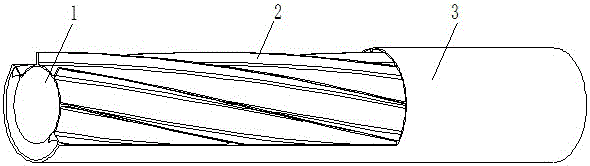

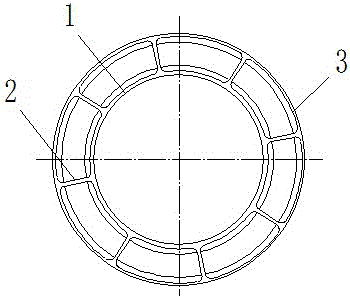

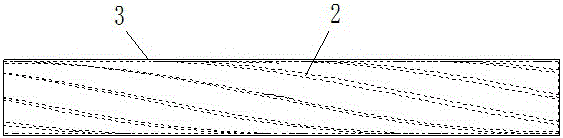

[0015] Embodiment 1: The core of the ground roller includes: an outer cylinder 3, an inner cylinder 1 and a support 2; the inner cylinder 1 is concentric with the outer cylinder 3, and there are several supports 2 between the inner cylinder 1 and the outer cylinder 3, and the support 2 is in the inner cylinder 1 and the outer cylinder 3 are evenly distributed in a spiral shape.

[0016] Both the inner cylinder 1 and the outer cylinder 3 are cylindrical.

[0017] The support 2 is a plurality of plate-shaped spiral rotating ribs, which extend in a spiral shape between the inner cylinder 1 and the outer cylinder 3, and both ends are connected with the inner cylinder 1 and the outer cylinder 3 at the same time to form a whole.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com