Manufacture method of fabrics blended by bamboo pulp fiber and tencel

A technology of bamboo pulp fiber and blended fabrics, which is applied in the field of home textiles, can solve the problems of poor tactility, skin-friendly comfort, large fiber hygroscopic expansion, and difficulty in controlling shrinkage, and achieve excellent moisture absorption and release performance and high-grade sense , Excellent natural antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

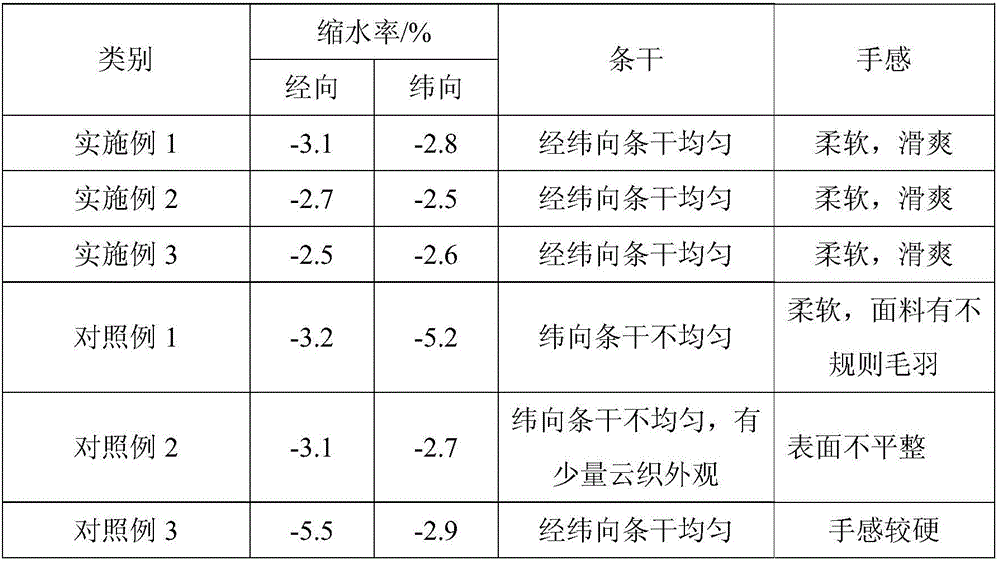

Embodiment 1

[0026] The warp yarn of the fabric is 40S siro compact spun bamboo pulp fiber and tencel blended fabric, wherein the mass percentage of bamboo pulp fiber in the yarn is 50%, and the weft yarn is 40S siro compact spun bamboo pulp fiber and tencel blended fabric, in which bamboo pulp fiber accounts for 50% of the yarn. The mass percentage of pulp fiber in the yarn is 50%, the fabric specification is 40S*40S / 140*80, and five pieces of three-flying satin weave. Among them, the specification of bamboo pulp fiber used in blended yarn is 1.33dtex*38mm, and the specification of tencel fiber is 1.33dtex*38mm

[0027] Benninger warping machines are used for the warping of the fabric, wherein the warping speed is 450m / min, and the tension of the yarns is controlled by zones to make the tension of the yarns uniform.

[0028] The fabric sizing is sized with modified starch, the sizing rate is 15%, the sizing speed is 45m / min, and the yarn elongation is controlled at 1%.

[0029] The way o...

Embodiment 2

[0036] The warp yarn of the fabric is 60S siro compact spun bamboo pulp fiber and tencel blended fabric, wherein the mass percentage of bamboo pulp fiber in the yarn is 30%, and the weft yarn is 60S siro compact spun bamboo pulp fiber and tencel blended fabric, of which bamboo The mass percentage of pulp fiber in the yarn is 30%, the fabric specification is 60S*60S / 182*120, and five pieces of three-flying satin weave. Among them, the specification of bamboo pulp fiber used in blended yarn is 1.33dtex*38mm, and the specification of tencel fiber is 1.33dtex*38mm

[0037] Benninger warping machines are used for the warping of the fabric, wherein the warping speed is 400m / min, and the tension of the yarns is controlled by zones to make the tension of the yarns uniform.

[0038] The fabric sizing is sized with modified starch, the sizing rate is 12%, the sizing speed is 40m / min, and the yarn elongation is controlled at 0.6%.

[0039] The way of fabric reeding is 2-in / reed, and the...

Embodiment 3

[0046] The warp yarn of the fabric is 40S siro compact spun bamboo pulp fiber and tencel blended fabric, wherein the mass percentage of bamboo pulp fiber in the yarn is 70%, and the weft yarn is 40S siro compact spun bamboo pulp fiber and tencel blended fabric, of which bamboo The mass percentage of pulp fiber in the yarn is 70%, the fabric specification is 40S*40S / 144*85, and five pieces of three-flying satin weave. Among them, the specification of bamboo pulp fiber used in blended yarn is 1.33dtex*38mm, and the specification of tencel fiber is 1.33dtex*38mm

[0047] Benninger warping machines are used for the warping of the fabric, wherein the warping speed is 450m / min, and the tension of the yarns is controlled by zones to make the tension of the yarns uniform.

[0048] The fabric sizing is sized with modified starch, the sizing rate is 15%, the sizing speed is 45m / min, and the yarn elongation is controlled at 1%.

[0049] The way of fabric reeding is 2-in / reed, and the wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com