A well-testing method for unstable wellhead pressure drop after acid fracturing

An acid fracturing and well testing technology, applied in wellbore/well components, measurement, earth-moving drilling and production, etc., can solve the problems of unstable well testing technical effect, long testing period, high testing cost, and reduce the risk of testing construction , The effect of saving test capital costs and saving test costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

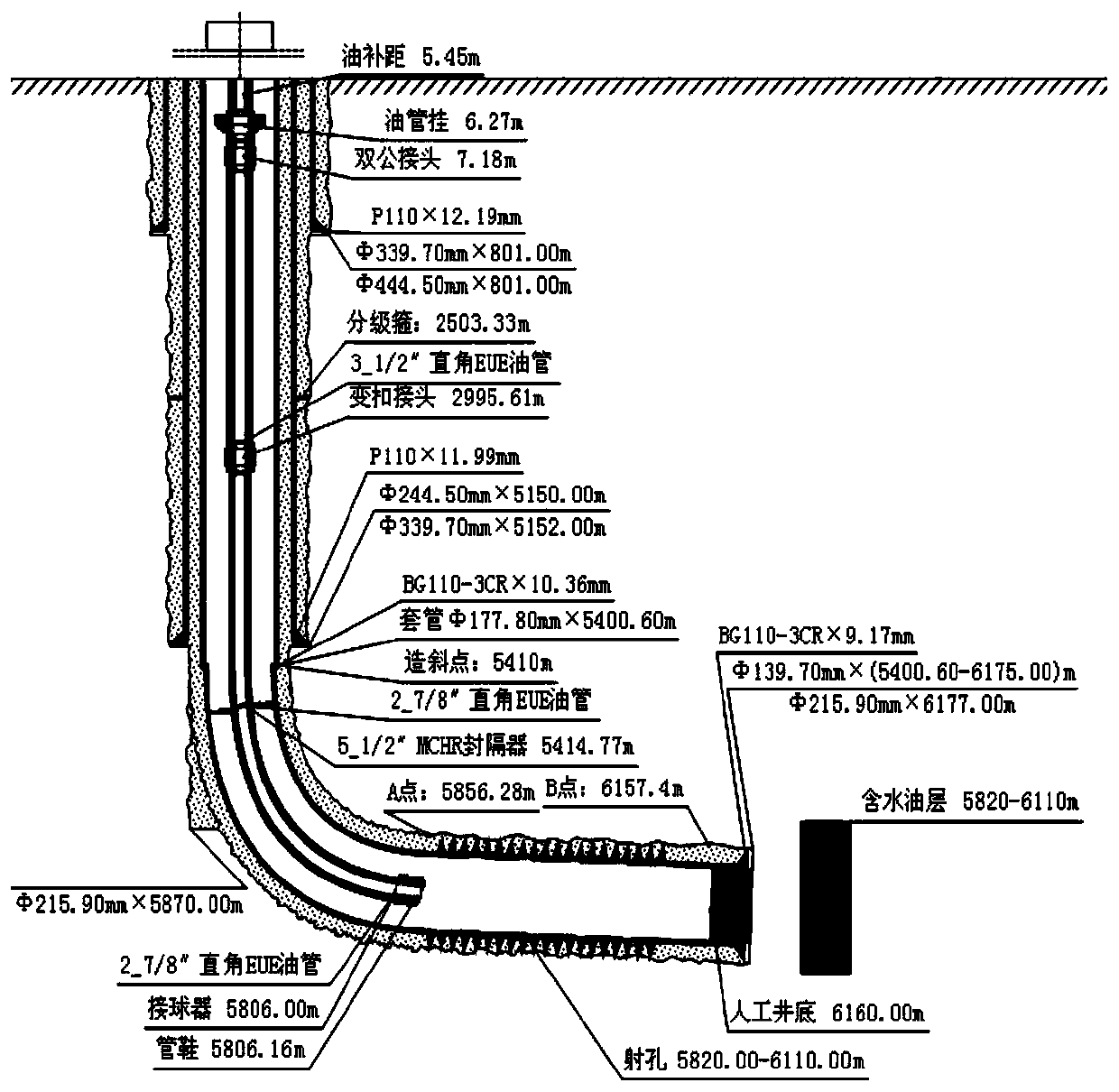

[0082] Geological overview of this example: the selected pressure drop test well is DH1-1GH, the well is a gas injection well, and the structural location is the Donghe No. 1 anticline in the Donghetang fault anticline zone of the Tabei uplift in the Tarim Basin. Casing, the drilled horizon is Carboniferous Donghe sandstone.

[0083] A well test method for unstable pressure drop at the wellhead after stopping the pump after acid fracturing, comprising the following steps:

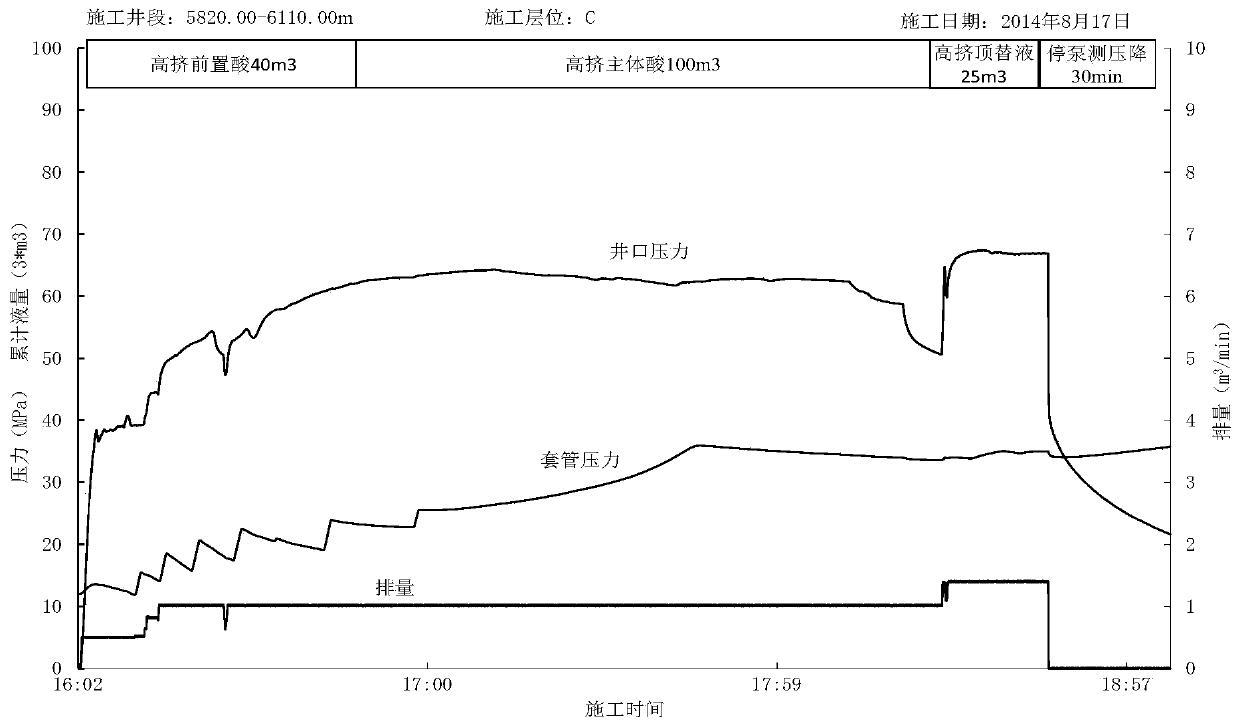

[0084] 1. During the acid fracturing process, install high-precision high-temperature and high-pressure storage or direct-reading electronic pressure gauges at the wellhead to record the wellhead pressure and casing pressure data. The data must include the pump pressure drop data at the wellhead when the pump is stopped. And draw the acidizing fracturing construction curve ( figure 1 ).

[0085] 2. Use the flowmeter to collect and record the displacement data of different fluids injected into the wellbore...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com