Sea/fresh water heat exchange system of marine water cooling diesel engine and heat exchange method

A technology of heat exchange system and diesel engine, applied in mechanical equipment, liquid cooling, engine components, etc., can solve problems such as potential safety hazards, high exhaust temperature, affecting engine power, etc., to ensure work stability, optimize the working environment, eliminate The effect of safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

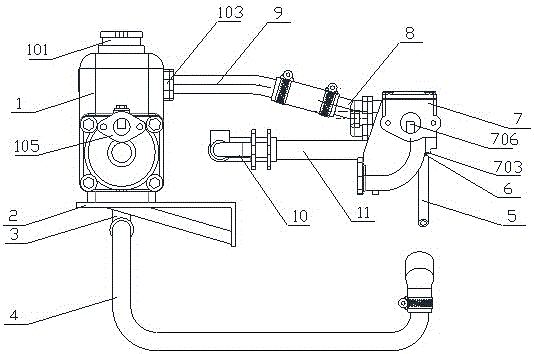

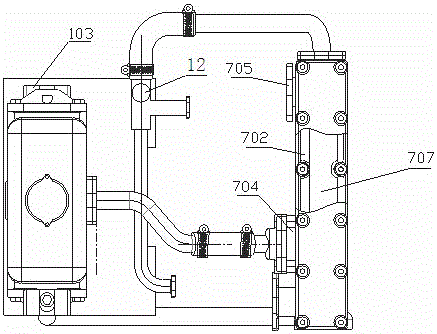

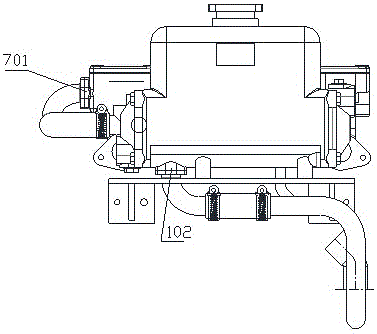

[0027] Depend on Figure 1-Figure 3 As shown, the marine water-cooled diesel engine sea-fresh water heat exchange system of the present invention includes a sea-fresh water heat exchanger 1, an exchanger bracket 2, an exchanger outlet pipe 3, an exchanger water pump connecting water pipe 4, a small circulation pipe 5, a small circulation pipe joint 6, Water-cooled exhaust pipe 7, thermostat cover 8, exchanger water inlet pipe 9, engine outlet pipe 10, exhaust pipe water inlet pipe 11, and rubber hose, clamps and bolts are also included to connect the above-mentioned components.

[0028] The sea-fresh water heat exchanger has 5 water ports, which are fresh water filling port 101, fresh water outlet 102, fresh water inlet 103, sea water inlet 104, and sea water outlet 105. When the diesel engine cooling water cycle is turned on, The se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com