Carbon fiber-resin composite material hydraulic cylinder barrel with integrated connecting structure

A resin composite material and connection structure technology, applied in the direction of cylinders, engine components, mechanical equipment, etc., can solve the problems of high maintenance cost of composite hydraulic cylinders, high quality of all-metal cylinders, and unsatisfactory power and weight of hydraulic cylinders. Improve equipment economy, light weight, maintenance difficulty and cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

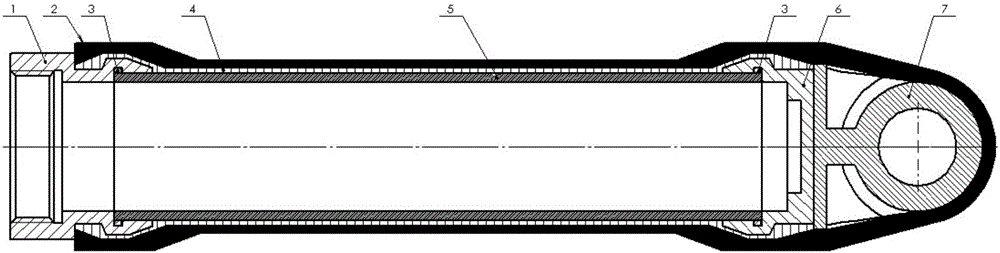

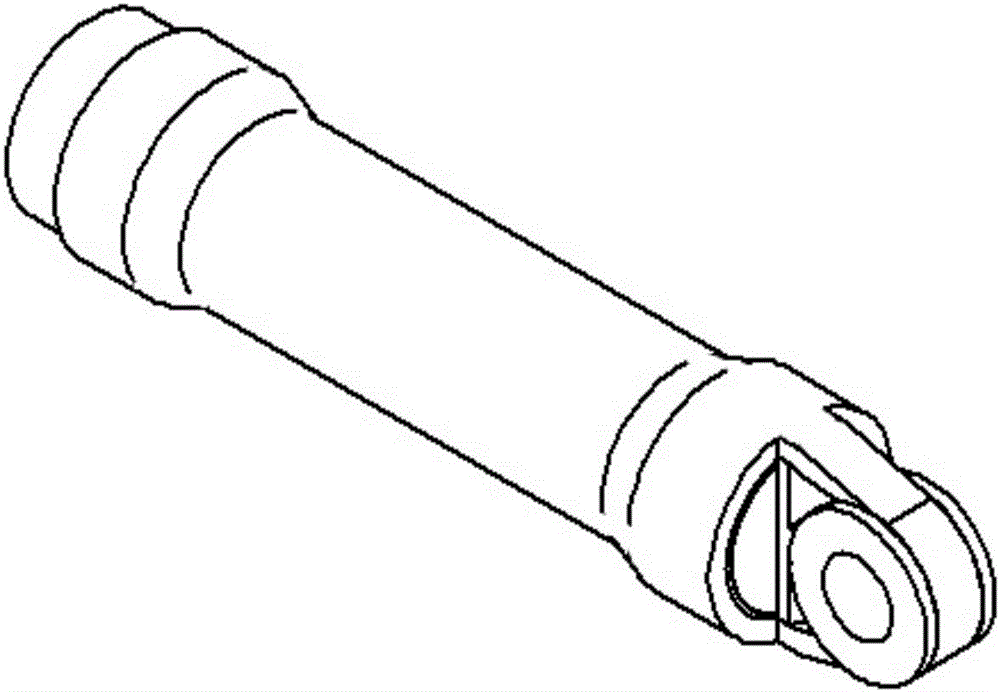

[0026] Such as figure 1 As shown, a carbon fiber-resin composite hydraulic cylinder barrel with an integrated connection structure provided by the present invention is similar in structure to a traditional hydraulic cylinder barrel, except that the outer layer 2 of the cylinder barrel and the tightly wound layer 4 are made of composite materials, and the sealing ring 3 In addition to selecting the corresponding standard parts according to the national standard, other parts are made of steel. The cylinder of the present invention includes a head coupling 1, a cylinder outer layer 2, a sealing ring 3, a tightly wound layer 4, a cylinder lining 5, a cylinder bottom 6, and hinged earrings 7; wherein, the head coupling 1, the sealing ring 3. The cylinder liner 5, the cylinder bottom 6, and the hinged earrings 7 together constitute the basic components of the cylinder; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com