Low-pressure pipeline pressurized leakage removing method

A low-pressure pipeline and pipeline technology, applied in the direction of pipe components, pipes/pipe joints/pipes, mechanical equipment, etc., can solve the problems that the pipeline system should not stop water, repair welding and eliminate leakage, and the effect is not ideal, and achieve leakage elimination. Good effect, easy operation, enhanced effect of plugging structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention is described in further detail below in conjunction with accompanying drawing:

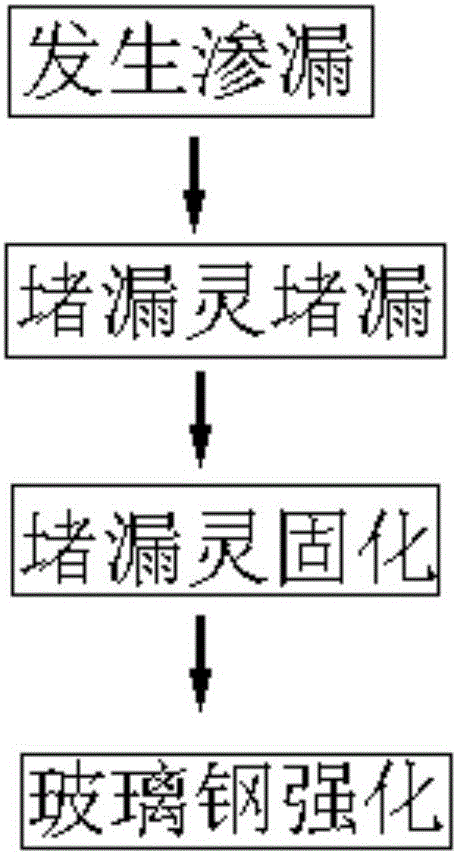

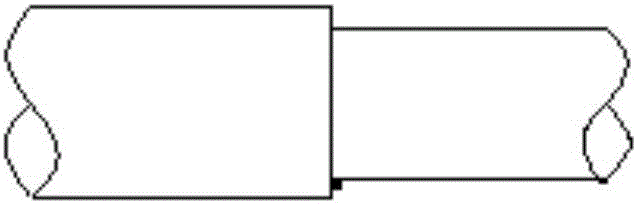

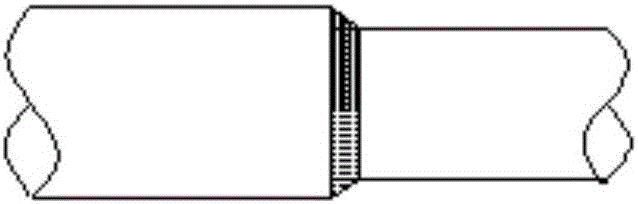

[0053] Such as Figure 1 to Figure 2(c) As shown, it is a schematic flow diagram of a method for eliminating leaks under pressure in a low-pressure pipeline of the present invention. When a leak occurs in a pipeline under pressure in a low-pressure process and it is not allowed to stop water and gas for maintenance, first extend the outer surface of the leaking part of the pipeline for 5 Use 60-100 mesh sandpaper to polish the range of ~10cm, so that the surface of the pipe is completely exposed to the matrix, which is convenient for bonding. Wet salt shape, knead into a hammer-shaped mass slightly larger than the diameter of the hole, quickly stuff the mass into the hole where the water gushes, and squeeze it with a hammered wooden stick, the mass will expand and solidify slightly in the hole, and at the same time The matrix reacts to form a solid whole,

[0054] If...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Gram weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com