Shape-memory alloy thermal-mechanical coupled multiaxial cyclic deformation experimental device

A memory alloy and cyclic deformation technology, used in measuring devices, instruments, scientific instruments, etc., can solve the problems of uneven phase transformation, uneven temperature inside and outside the heating sample, and long time, so as to improve accuracy and ensure integrity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

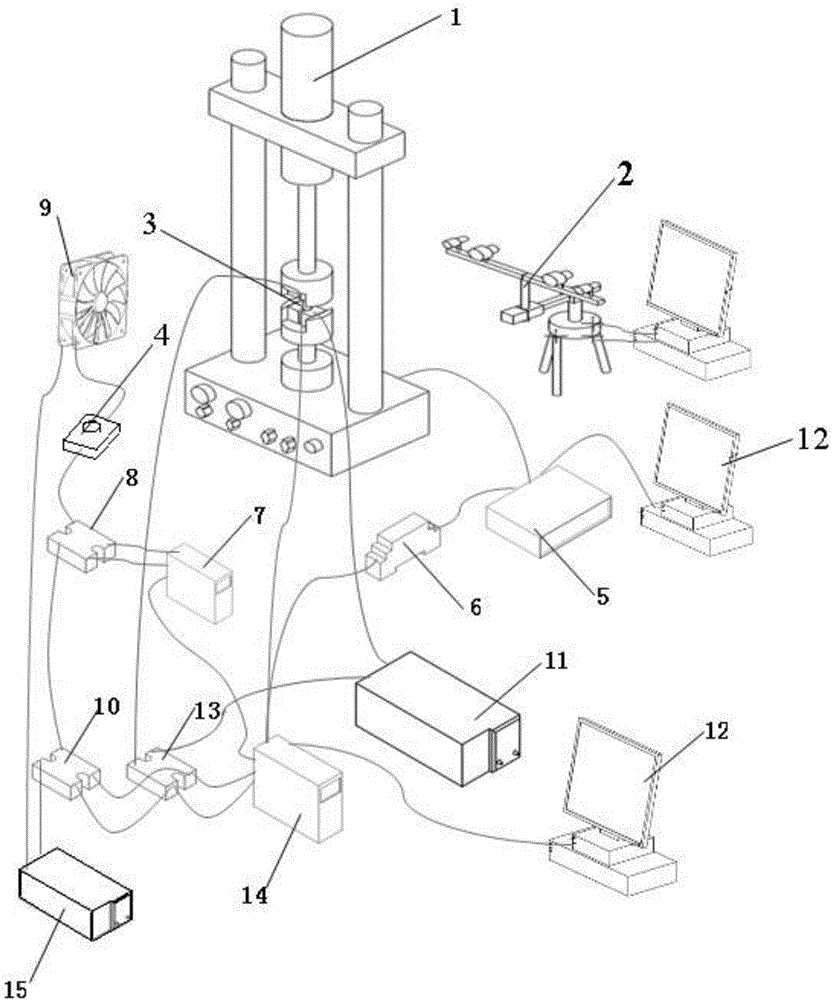

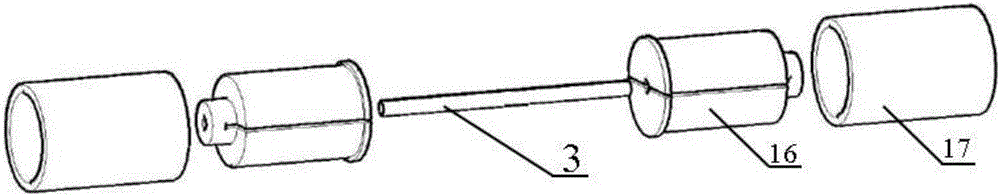

[0022] Such as figure 1 , 2 As shown, a thermal-mechanical coupling multi-axis cyclic deformation experiment device for shape memory alloys includes an MTS testing machine 1 and an MTS controller 5 connected thereto; Measuring device 2, the optical strain measuring device 2 is connected to the MTS controller 5; it also includes a first temperature controller 14 and a temperature sensor for measuring the temperature of the test sample 3 of the MTS testing machine; the temperature sensor is connected to the MTS through a transmitter 6 Controller 5; also includes a DC heating power supply 11, the positive and negative poles of which are connected to the two ends of the test sample 3 of the MTS testing machine; a first relay 13 is arranged between the DC heating power supply 11 and the testing sample 3 of the MTS testing machine, and the first rel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com