Experiment device and method for simulating hole diameter variations in tight oil depletion development process

A technology of oil depletion and production process, applied in the direction of nuclear magnetic resonance analysis, etc., can solve the problems of accuracy of test results, insufficient representativeness, inability to consider the influence of ground stress difference, and inability to simulate the physical process of tight oil, etc., to achieve Improve the production level and oil yield, strong representativeness, and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

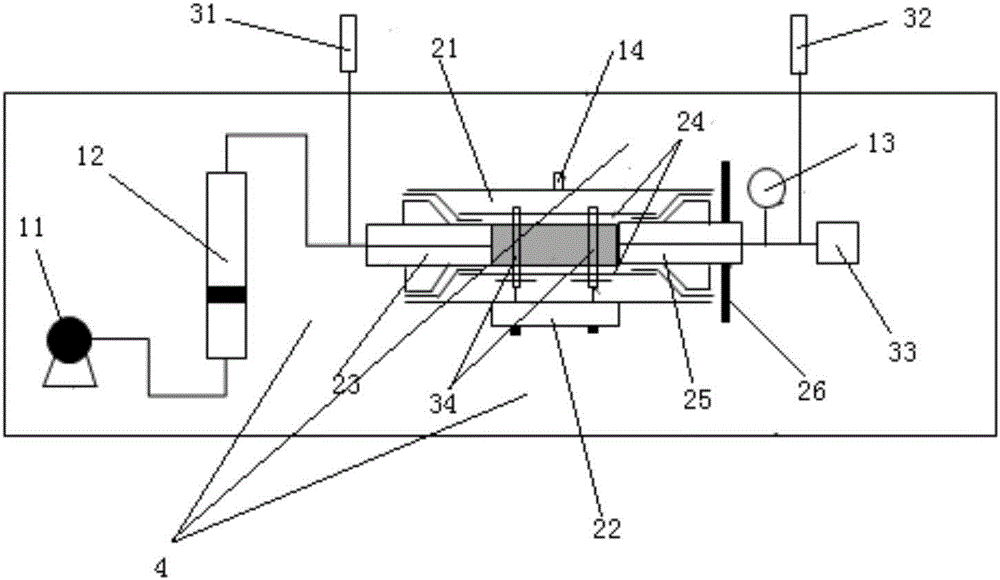

[0047] Embodiment 1: see figure 1 A device for simulating the change state of core pore diameter in the process of tight oil depletion production, which includes: a core pressure loading unit (1), a core holder (2), a core data acquisition unit (3), a nuclear magnetic resonance instrument (4 );

[0048] The core pressure loading unit (1) is used to simulate the pressure carried by the core in the process of tight oil depletion production, including: ISCO pump (11), left working fluid piston container (12), right back pressure valve (13) , confining pressure valve (14); the ISCO pump (11) is used to push the piston in the left working fluid piston container (12) with a pressure below 40MPa; the left working fluid piston container (12) is used for Pumping neutral kerosene to apply a displacement pressure below 40MPa to the core through the inner tube of the core holder to tighten the plug (23) to the left; the right back pressure valve (13) is used to tighten The inner tube of...

Embodiment 2

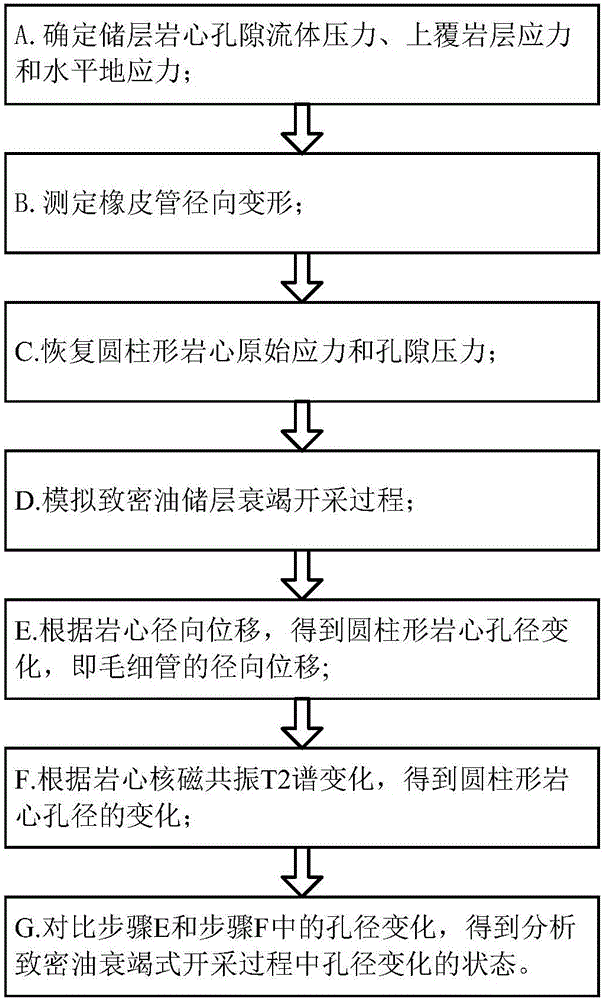

[0052] Example 2: see figure 2 A method for measuring the change state of the core pore diameter in the process of tight oil depletion production, which uses the above-mentioned device for simulating the change state of the core pore diameter in the process of tight oil depletion production, and includes the following steps:

[0053] A. Determine reservoir core pore fluid pressure, overlying strata stress and horizontal ground stress;

[0054] Suppose: the formation water density is ρ w , the reservoir depth is h, the gravitational acceleration is g, and the formation density is ρ s , the tectonic stress is σ s , the rock Poisson's ratio is v;

[0055] but:

[0056] The pore fluid pressure Pp is:

[0057] P p = ρ w gh

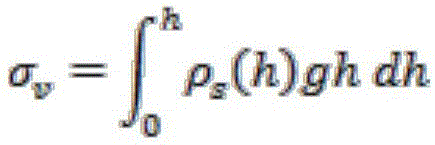

[0058] Overburden pressure σv is:

[0059]

[0060] The horizontal stress σh is:

[0061] σ h =vσ v +σ s

[0062] B. Measure the radial deformation of the rubber tube;

[0063] Put a 2.5cm solid cylindrical steel fake core into the rubber tub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com