Hypersonic velocity pointed conical appearance heat flux density modeling approach based on functional optimization

A heat flux density, hypersonic technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of inconsistent heat flux distribution rules, lack of theoretical methods, etc., to ensure prediction accuracy, reduce interference, and be concise. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

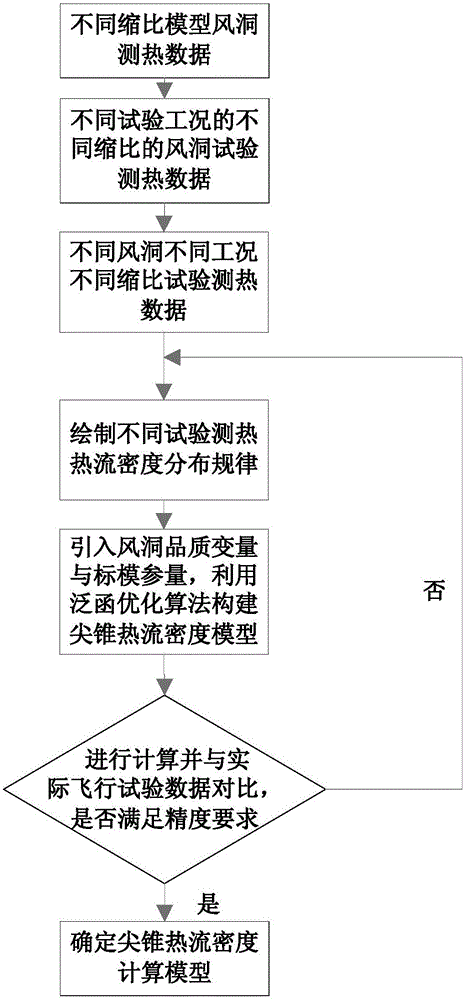

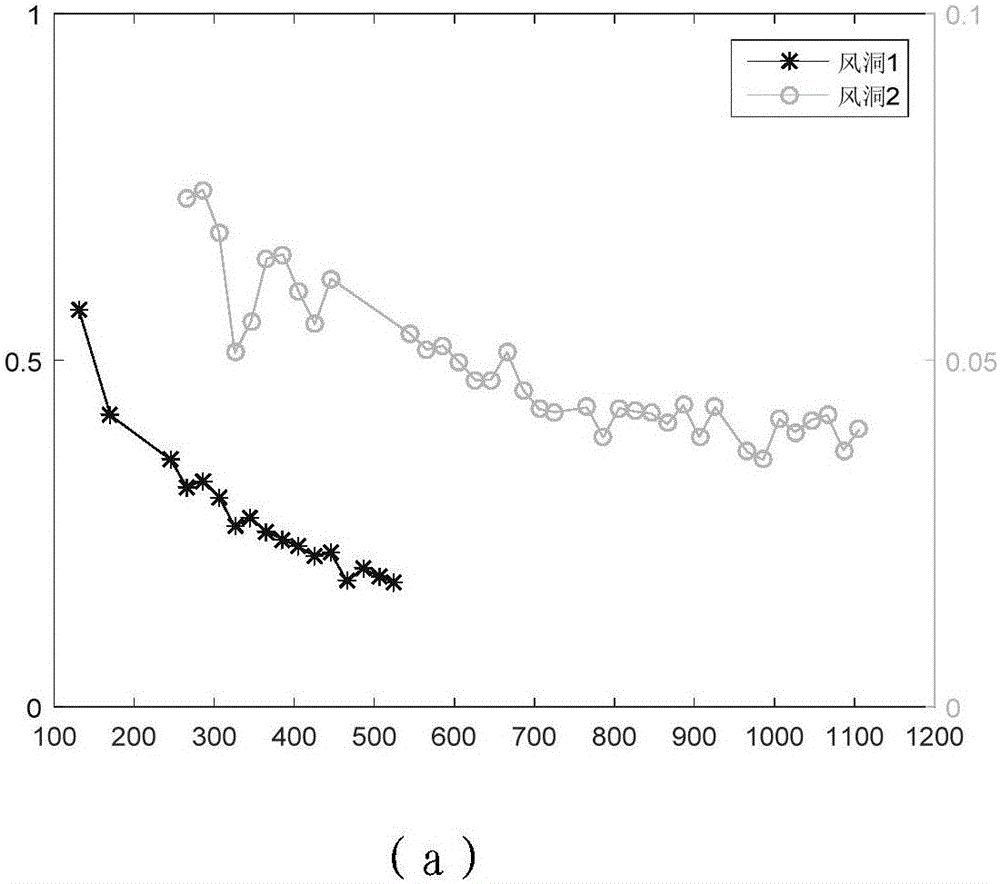

[0030] The flow chart of the present invention is as figure 1 As shown in Fig. 1, firstly, cone calorimetry tests with different scales are carried out in different types of hypersonic wind tunnels to obtain high-precision and differentiated aerothermal test data reflecting different physical mechanisms, and draw the heat flux distribution laws of different tests to judge the laws Whether it is uniform, if not, perform space transformation under the guidance of functional optimization, and iterate continuously until a uniform distribution law is obtained.

[0031] Provide concrete implementation steps of the present invention below in conjunction with specific example:

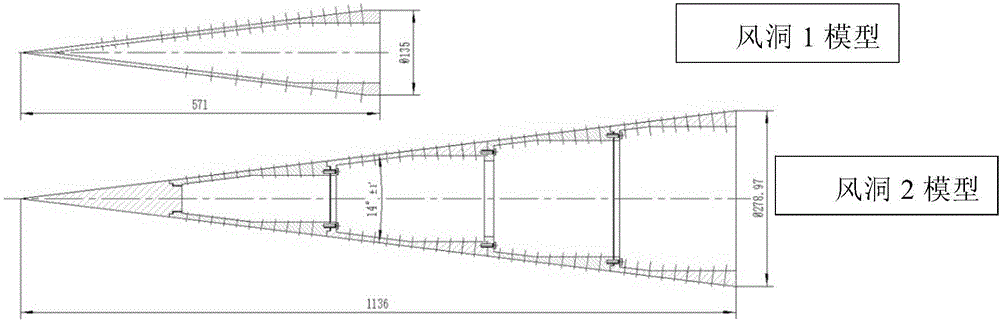

[0032] (1) Using a hypersonic thermal wind tunnel, conduct ground thermal tests on two cone models of the aircraft with different scales. Two scaled cone models such as figure 2 As shown, the heat measurement test is carried out in wind tunnel 1 and 2, wherein the test model is a pointed cone with a half-co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com