Rear cover of electronic equipment and rear cover preparation method

A technology of electronic equipment and back cover, which is applied in the direction of chassis/cabinet/drawer parts, metal casing, etc., can solve the problems of high cost, cumbersome processing process, weak overall strength of the back cover, etc., and achieves high mass production. , low cost, dimensionally stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The back cover provided in this embodiment can be applied to electronic equipment, which includes but not limited to mobile terminals, computers, televisions and other equipment.

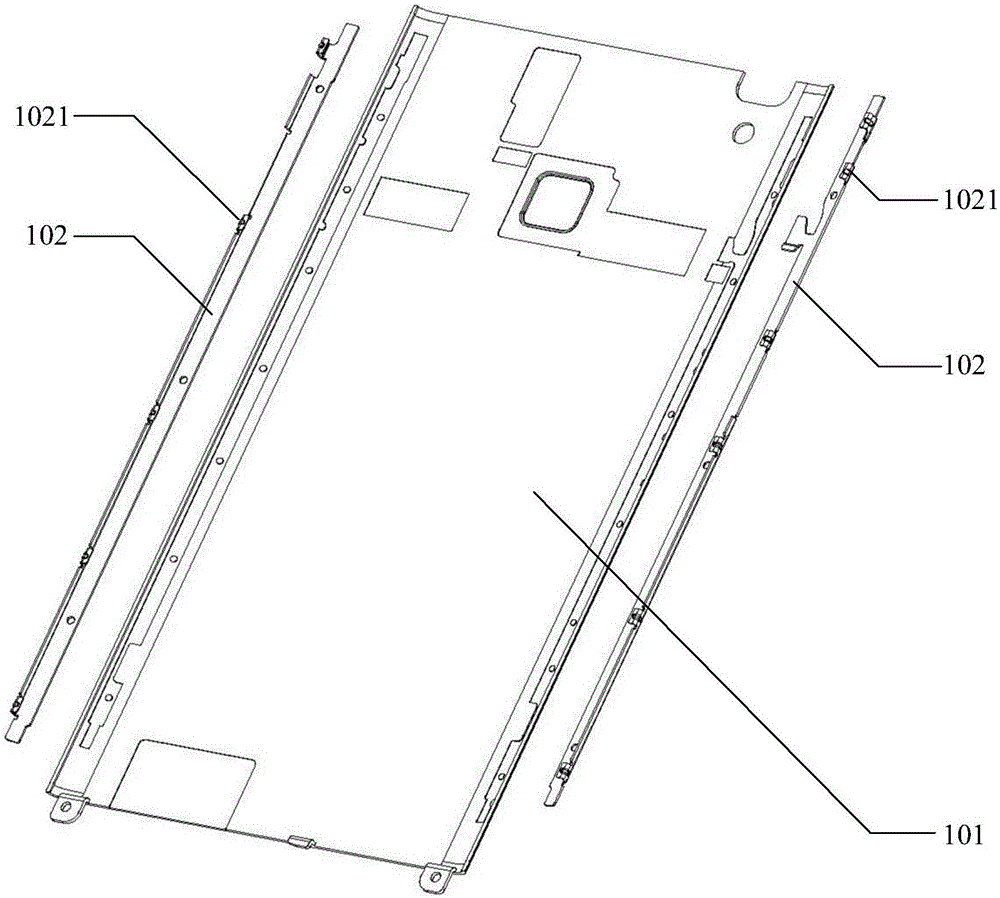

[0025] refer to figure 1 , shows a schematic structural diagram of a rear cover of an electronic device in an embodiment of the present invention.

[0026] The back cover includes: a back cover body 101 and a buckle bracket 102 .

[0027] Wherein, the buckle bracket 102 includes a connection buckle 1021, and the connection buckle 1021 is used to connect the back cover to the device body of the electronic device. Specifically, the connecting buckle 1021 is buckled and connected with the buckle corresponding to the device body of the electronic device, so as to realize the assembly of the back cover and the body of the electronic device. For example, if the electronic device is a mobile phone, the back cover is the battery cover of the mobile phone, and the battery cover can be freely disasse...

Embodiment 2

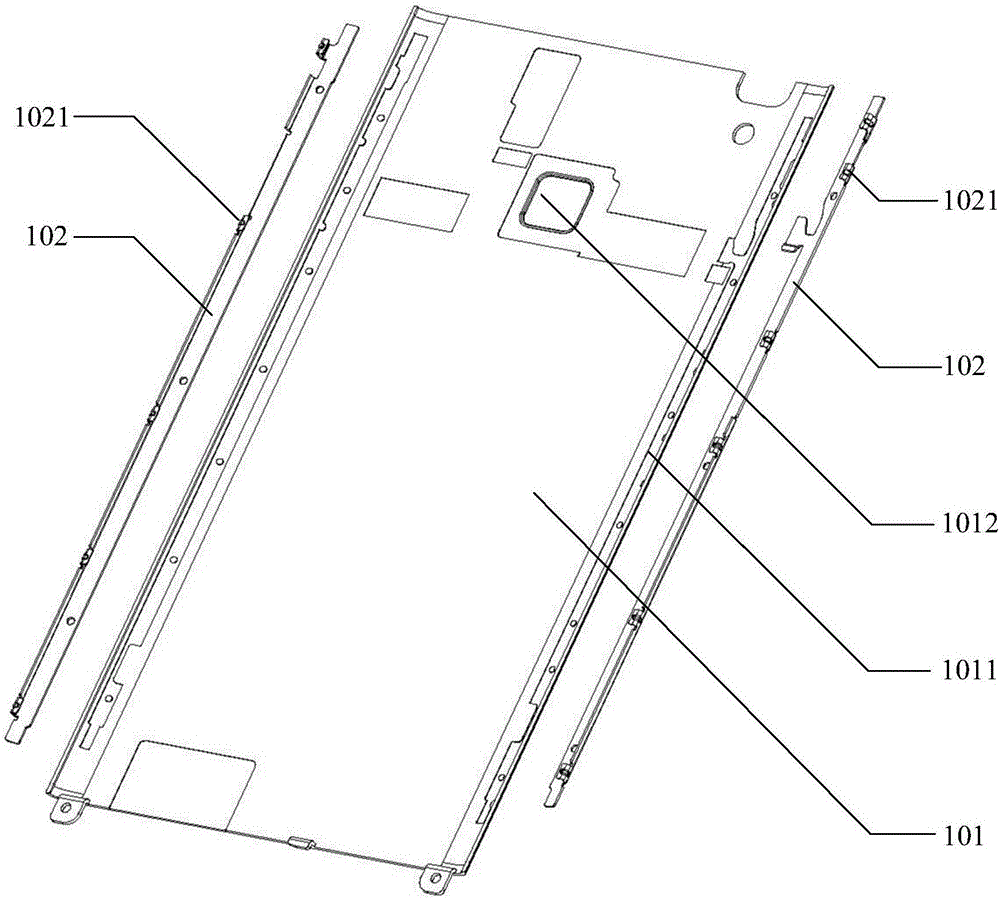

[0034] refer to figure 2 , shows a schematic structural diagram of another electronic device back cover in an embodiment of the present invention, and the back cover provided in this embodiment is a preferred embodiment based on the first embodiment.

[0035] The back cover specifically includes: a back cover body 101 and a buckle bracket 102 . In this embodiment, the rear cover body 101 includes a glue overflow groove 1011 and a hole 1012 .

[0036] Wherein, the glue overflow groove 1011 is a groove formed by etching, located on the surface of the connecting end of the back cover body 101 and the buckle bracket 102, and the depth of the glue overflow groove 1011 depends on the thickness of the back cover body. When dispensing the back cover body 101 and the buckle bracket 102, the overflow groove 1011 can be used to limit the area covered by the hot melt glue, prevent the liquid hot melt glue in a high temperature state from overflowing during dispensing, and avoid non-conn...

Embodiment 3

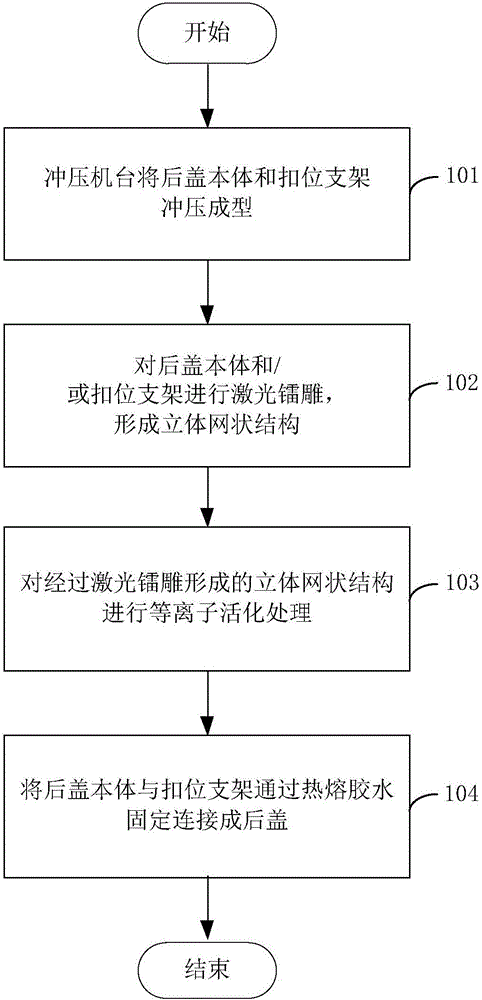

[0044] An embodiment of the present invention provides an electronic device, which adopts the back cover described in the above embodiment. Then the electronic device includes a device body and a back cover, and the back cover is fastened on the device body.

[0045] The back cover includes: a back cover body and a buckle bracket.

[0046] Wherein, the buckle bracket includes a connection buckle, and the connection buckle is used to connect the back cover to the device body of the electronic device. Specifically, the connecting buckle is buckled and connected with the buckle corresponding to the device body of the electronic device, so as to realize the assembly of the back cover and the device body.

[0047] The back cover body and the buckle bracket are prepared separately and independently, so both the back cover body and the buckle bracket can be formed by stamping, and can be made of different metals.

[0048] After the back cover body and the buckle bracket are separat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com