Manufacturing technique for honeycomb chassis thin wall

A manufacturing process and thin-walled technology, which is applied in the thin-walled manufacturing process of honeycomb chassis, can solve the problems of increased chassis size error, increased manufacturing cost, time-consuming assembly, etc., and achieve the effects of increased strength, cost saving, and reliable connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] refer to Figure 1-Figure 4 As shown, in this embodiment, a thin-walled manufacturing process of a honeycomb chassis is characterized in that the process includes the following steps:

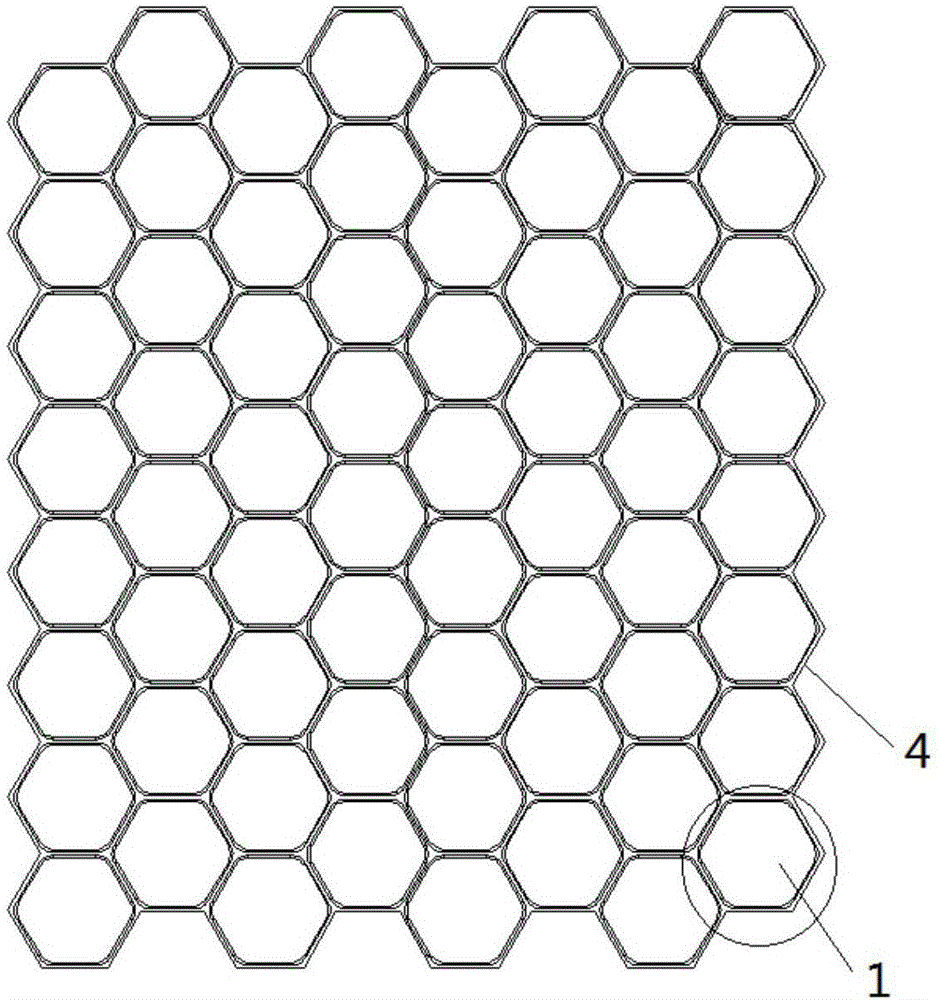

[0019] This process adopts a die-casting process, and sixty-four hexagonal thin-walled honeycomb structures 1 can be die-casted each time.

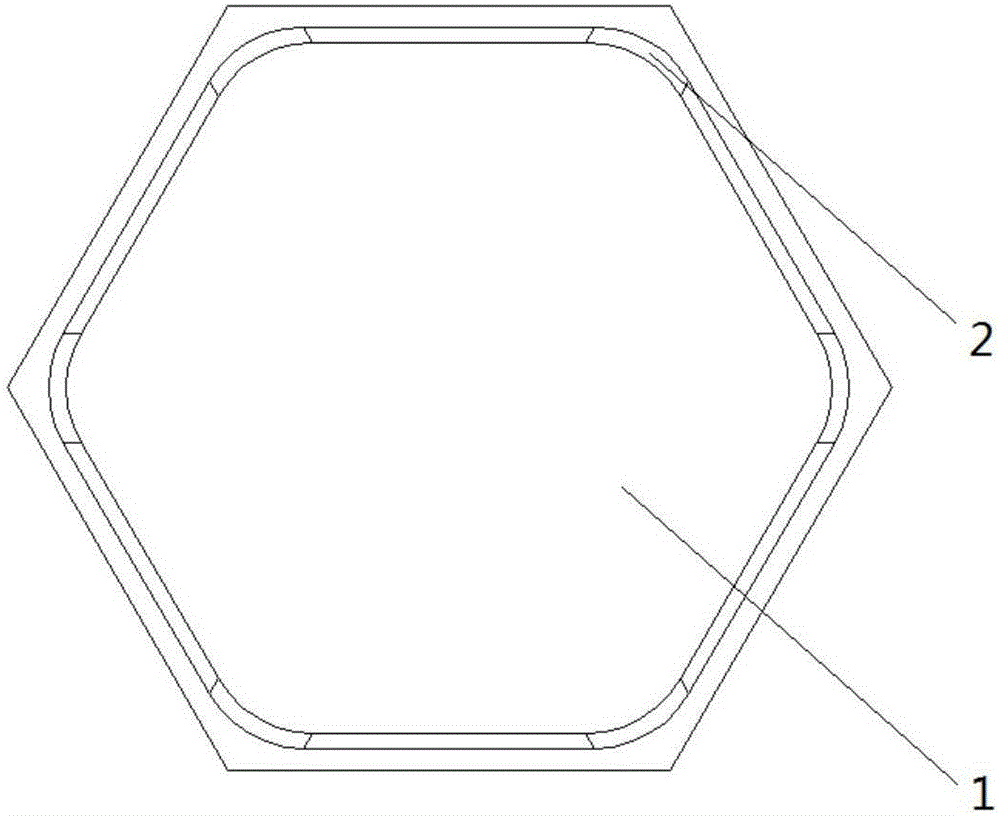

[0020] The transition fillet 2 can increase the strength of the honeycomb chassis and meet the production process requirements during die-casting, and the entire thin-walled honeycomb structure is demoulded by the ejector pin at this fillet.

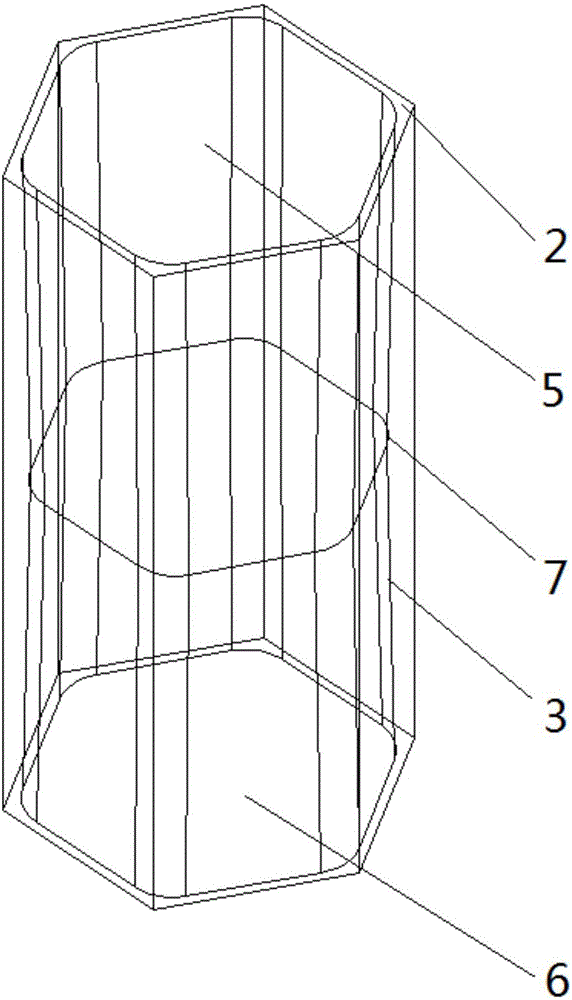

[0021] The workpiece produced by die-casting will be heavier than the mass of profile extrusion. To solve this problem, double-sided drafting is used. The drafting end point 7 is in the middle of the hexagonal thin-walled honeycomb structure, and the drafting is carried out from the upper end surface and the lower end surface to the middle part at the same time, forming a special honeycomb structure with a th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com