A welding tool for titanium alloy mounting ring and molybdenum grid and electron beam welding process

A technology of electron beam welding and welding tooling, which is applied in the direction of electron beam welding equipment, welding/welding/cutting items, welding equipment, etc., can solve the problem of reducing working capacity and service life, very strict dimensional accuracy requirements, and structural parts dimensional accuracy reduce the problem, achieve the effect of reducing the complexity and weight of the structure, improving the overall performance of the joint, and reducing the heat-affected zone

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

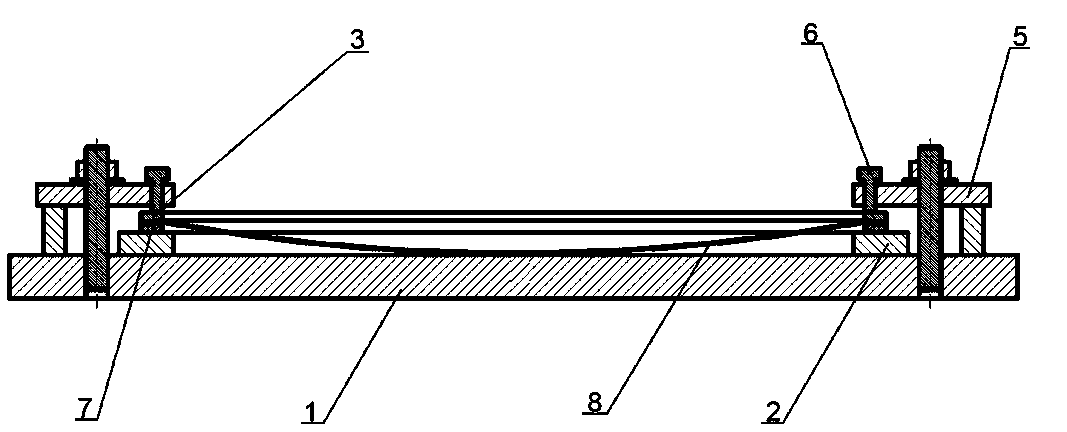

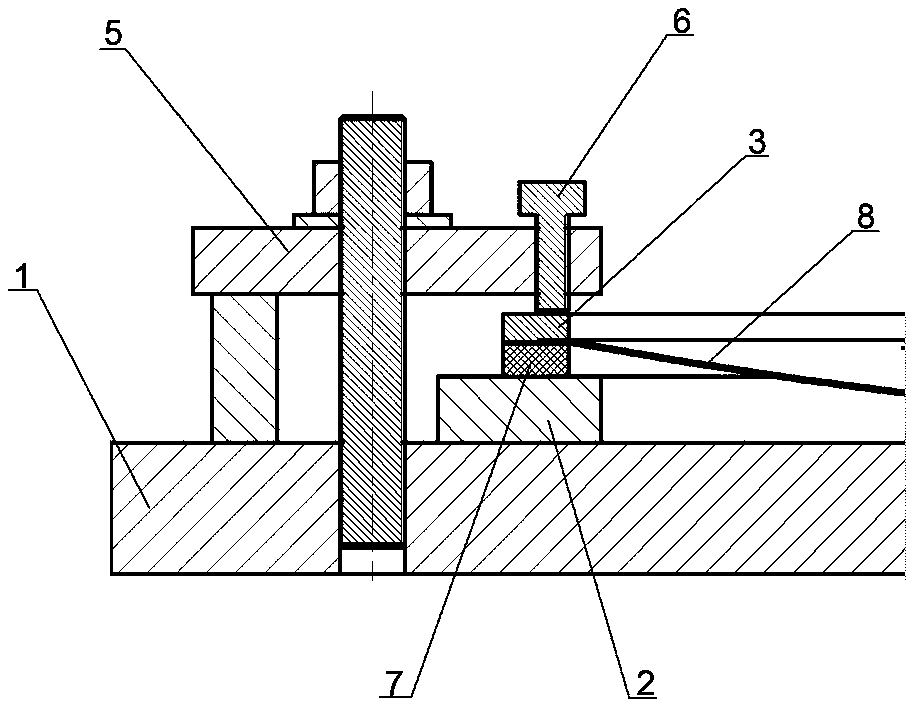

[0027] Below in conjunction with embodiment and accompanying drawing, the present invention will be further described:

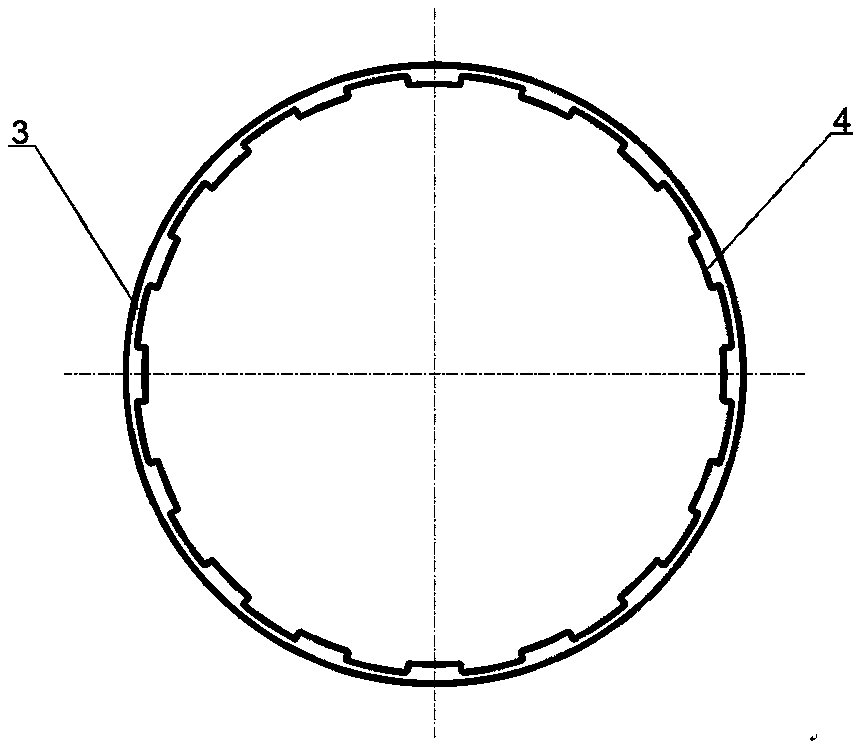

[0028] Such as Figure 1-3 Shown: a welding tooling for a titanium alloy mounting ring and a molybdenum grid, including a base 1, an annular backing plate 2, an upper pressure ring 3 and a plurality of pressing sets, and the annular backing plate 2 is fixed on the upper end surface of the base 1 A space for clamping the titanium alloy installation ring 7 is formed between the annular backing plate 2 and the upper pressure ring 3, and a plurality of pressure blocks 4 for clamping the molybdenum grid 8 are distributed on the inner peripheral surface of the upper pressure ring 3 at intervals 16 briquetting blocks 4 are distributed on the inner circumferential surface of the upper pressing ring 3 in the present embodiment according to the interval ratio of 1:1, and the horizontal position of the lower end surface of the pressing blocks 4 is higher than that of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com