Water-based ink for printing thin film and preparation method thereof

A water-based ink and film printing technology, applied in the field of printing ink, can solve the problems of insufficient dispersibility, gloss and water resistance, reduce use efficiency, long curing time, etc., achieve good gloss and dispersibility, and fast drying speed , printing effect lasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

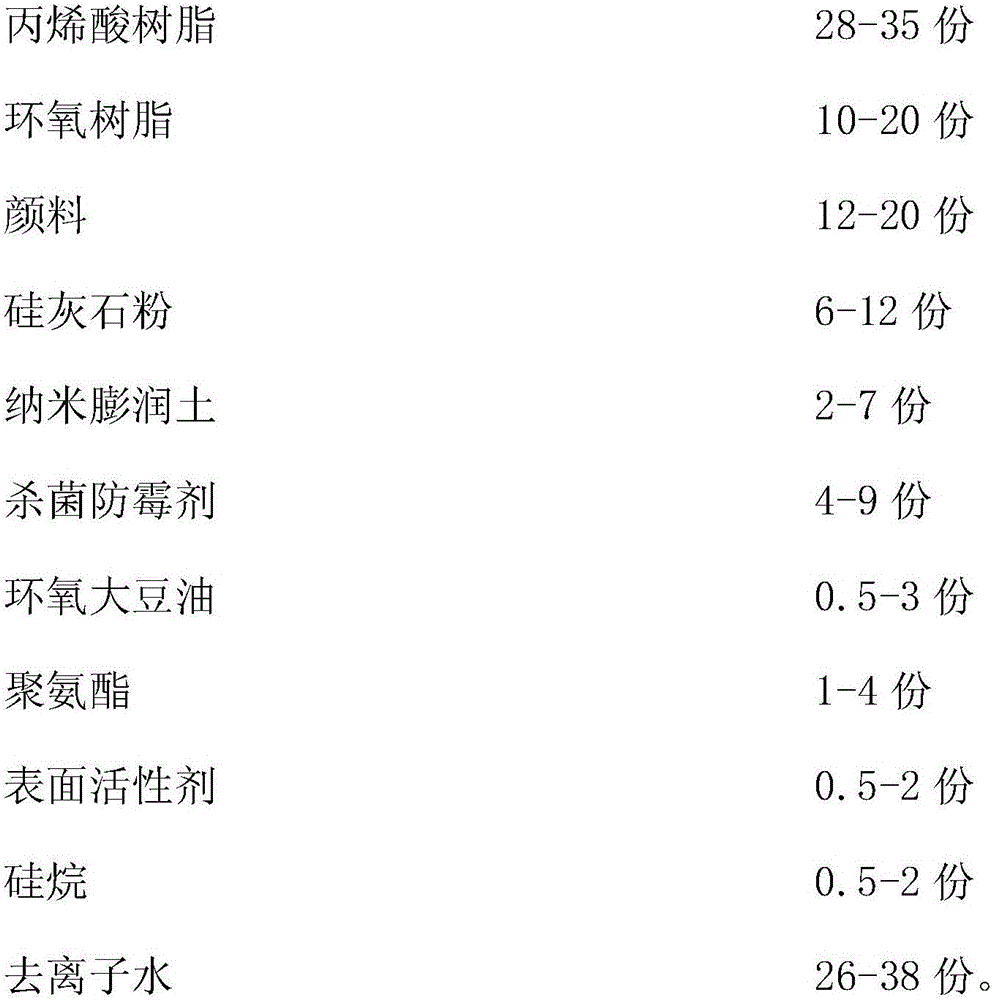

Embodiment 1

[0026] A water-based ink for film printing, consisting of the following raw materials in parts by weight: 28 parts of acrylic resin, 10 parts of epoxy resin, 12 parts of pigment, 6 parts of wollastonite powder, 2 parts of nano bentonite, 4 parts of bactericidal and antifungal agent, epoxy 0.5 part of soybean oil, 1 part of polyurethane, 0.5 part of surfactant, 0.5 part of silane, 26 parts of deionized water; the pigment is one of phthalocyanine blue, titanium dioxide or permanent red; the surfactant is sulfate ester.

[0027] Among them, the preparation method of the fungicide antifungal agent is: 15 parts of mint, 12 parts of Sophora flavescens, 8 parts of clove, 10 parts of comfrey, 5 parts of berberine, 9 parts of camphor, 6 parts of kujianpi, and 14 parts of honeysuckle are added to 2 Double the weight of water, decoct 3 times, 40min each time, filter, combine the three filtrates, cool and concentrate to obtain the bactericidal and antifungal agent.

[0028] A preparation ...

Embodiment 2

[0035] A water-based ink for film printing, consisting of the following raw materials in parts by weight: 35 parts of acrylic resin, 20 parts of epoxy resin, 20 parts of pigment, 12 parts of wollastonite powder, 7 parts of nano bentonite, 9 parts of bactericidal and antifungal agent, epoxy 3 parts of soybean oil, 4 parts of polyurethane, 2 parts of surfactant, 2 parts of silane, 38 parts of deionized water; the pigment is one of phthalocyanine blue, titanium dioxide or permanent red; the surfactant is sulfuric acid ester.

[0036] Among them, the preparation method of the antifungal agent is as follows: 22 parts of mint, 20 parts of Sophora flavescens, 15 parts of clove, 15 parts of comfrey, 10 parts of coptis, 13 parts of camphor, 12 parts of bittern bark, and 18 parts of honeysuckle are added to 3 Double the weight of water, decoct 3 times, 50min each time, filter, combine the three filtrates, cool and concentrate to obtain the bactericidal and antifungal agent.

[0037] A p...

Embodiment 3

[0044] A water-based ink for film printing, consisting of the following raw materials in parts by weight: 30 parts of acrylic resin, 14 parts of epoxy resin, 15 parts of pigment, 8 parts of wollastonite powder, 4 parts of nano bentonite, 5 parts of bactericidal and antifungal agent, epoxy 1 part of soybean oil, 2 parts of polyurethane, 1 part of surfactant, 1 part of silane, 32 parts of deionized water; the pigment is one of phthalocyanine blue, titanium dioxide or permanent red; the surfactant is sulfuric acid ester.

[0045] Among them, the preparation method of the antifungal agent is: add 18 parts of mint, 15 parts of Sophora flavescens, 10 parts of clove, 12 parts of comfrey, 8 parts of berberine, 10 parts of camphor, 8 parts of bitter bark, and 15 parts of honeysuckle into 3 times the weight of water, decocted 3 times for 55 minutes each time, filtered, combined the three filtrates, cooled and concentrated to obtain the bactericidal antifungal agent.

[0046] A preparati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com