Drilling fluid for improving mudstone drilling speed, preparation method and application thereof

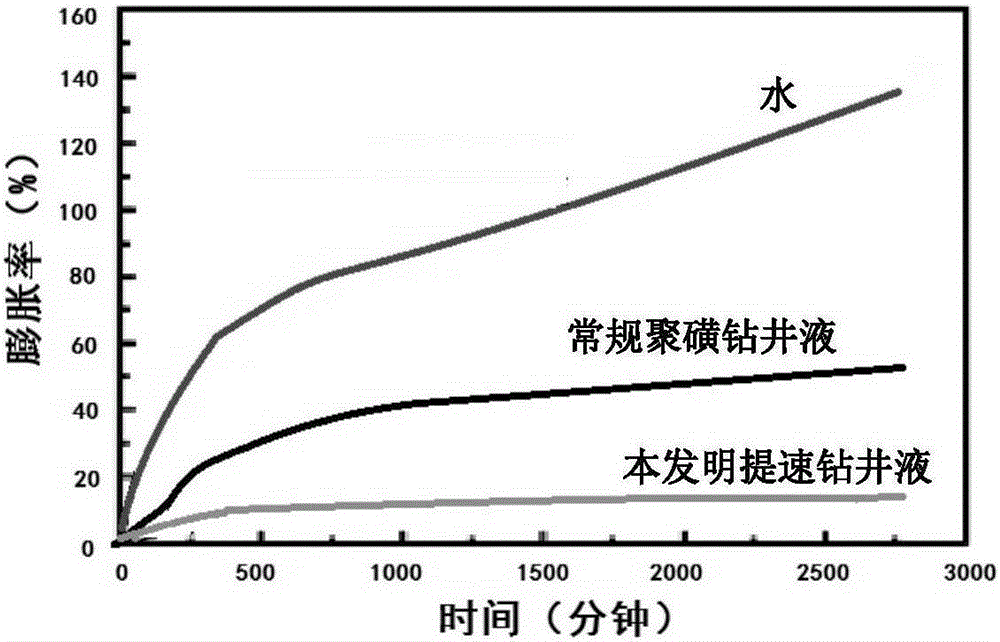

A drilling speed and drilling fluid technology, applied in the field of drilling, can solve the problems that the drilling speed cannot be significantly improved, the oil-based drilling fluid is easy to pollute the environment, and the cost of the synthetic-based drilling fluid is high, and achieves strong inhibition and cleanliness. , Avoid water swelling and dispersion, reduce the effect of reservoir damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

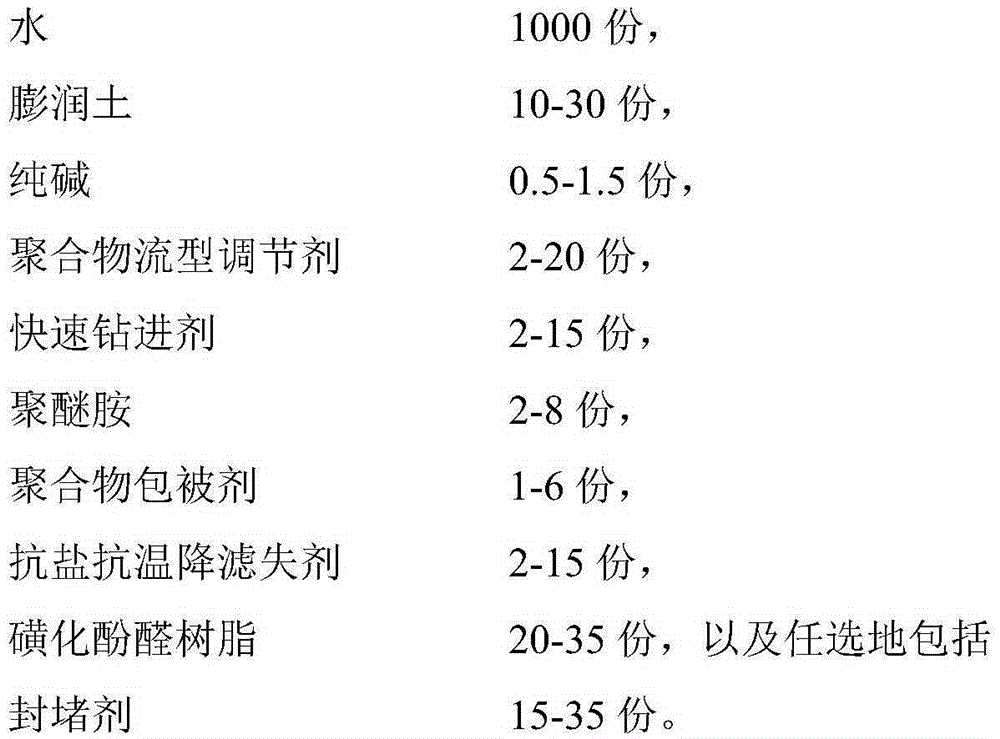

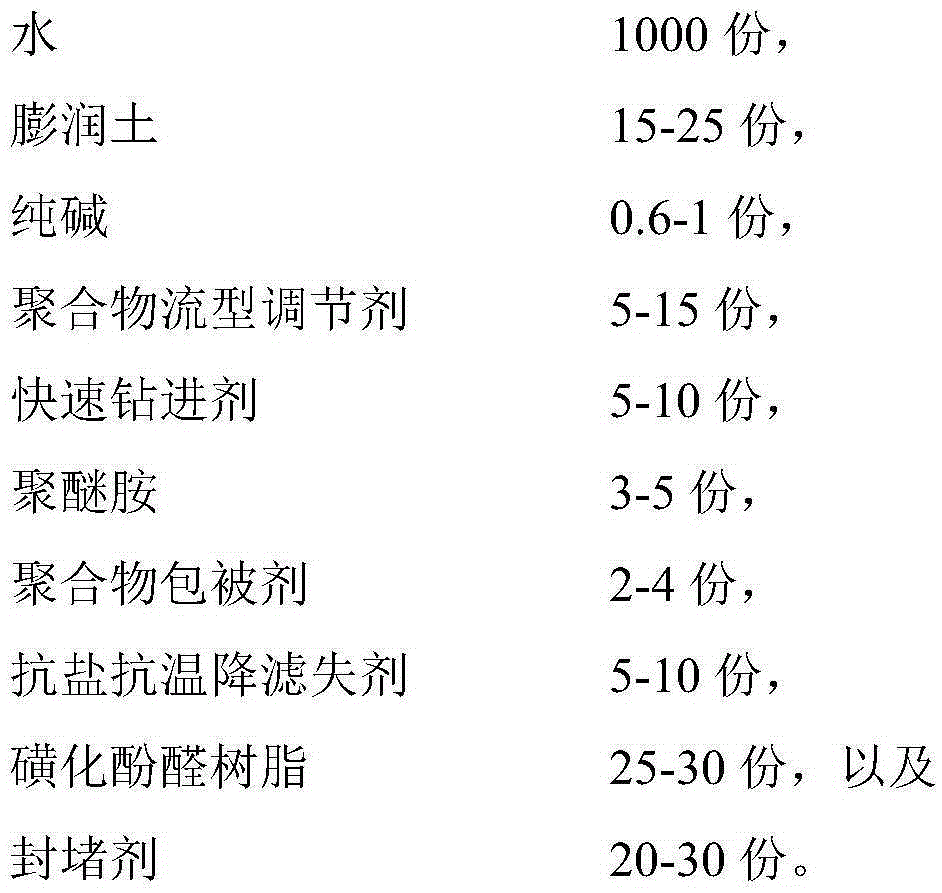

[0035] Add 25 parts of bentonite and 1 part of soda ash in 1000 parts (below are parts by weight) of water, leave standstill maintenance 24 hours after stirring for 4 hours, then add 5 parts of low-viscosity anionic cellulose, 2 parts of hydrolysis degree while stirring. 30%, PHPA with a molecular weight of 3 million, 5 parts of treatment agent RE, 3 parts of SDPA, 5 parts of temperature-resistant and salt-resistant fluid loss reducer, 25 parts of SMP-1 resin and 20 parts of asphalt, continue to stir for 20 minutes and then stand for later use .

Embodiment 2

[0037]Add 25 parts of bentonite and 1 part of soda ash to 1000 parts of water, stir for 4 hours and let it stand for 24 hours, then add 15 parts of high-viscosity polyanionic cellulose, 4 parts of cellulose with a hydrolysis degree of 40% and a molecular weight of 5 million while stirring. PHPA, 10 parts of treatment agent RE, 4 parts of D230, 10 parts of heat-resistant and salt-resistant fluid loss reducer, 30 parts of SMP-2 resin and 20 parts of shielding temporary plugging agent FD-1, continue to stir for 20 minutes and then stand for later use.

Embodiment 3

[0039] Add 10 parts of bentonite and 0.5 parts of soda ash to 1000 parts of water, stir for 4 hours and let it stand for 24 hours for curing, then add 2 parts of low-viscosity carboxymethyl cellulose, 2 parts of hydrolysis degree of 70% and molecular weight of 6 million while stirring PHPA, 5 parts of treatment agent RE, 2 parts of NH-1, 5 parts of temperature-resistant and salt-resistant fluid loss reducer, 20 parts of SMP-1 resin and 20 parts of asphalt, continue to stir for 20 minutes and then stand for later use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com