Robotic Flexible Measuring System for 3D Topography of Large and Complex Surfaces

A complex surface and measurement system technology, applied in the field of large complex surface three-dimensional shape robot flexible measurement system, can solve the problems of inability to realize online measurement, lack of flexibility of measuring equipment, and need to improve measurement efficiency, and achieve a small footprint , large working range, and the effect of improving the degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further elaborated below in conjunction with the accompanying drawings.

[0028] The robot flexible measurement system for the three-dimensional shape of large complex curved surfaces of the present invention includes an industrial robot, a robot control cabinet, a two-axis positioner, a safety light curtain, a safety fence, an IGPS transmitter and an IGPS receiver;

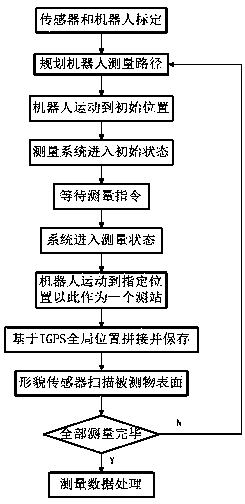

[0029] See attached figure 1 , the measurement method of this measurement system includes the following steps:

[0030] Step 1: Establish a complex surface measurement system model;

[0031] a. Establish the mathematical model of the structured light sensor in the scanning measurement system according to the measurement principle of the shape measurement sensor;

[0032] b. Establish the D-H model of the robot and the positioning error model of the robot according to the robot pose description method, and establish the hand-eye calibration mathematical model of the measureme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com