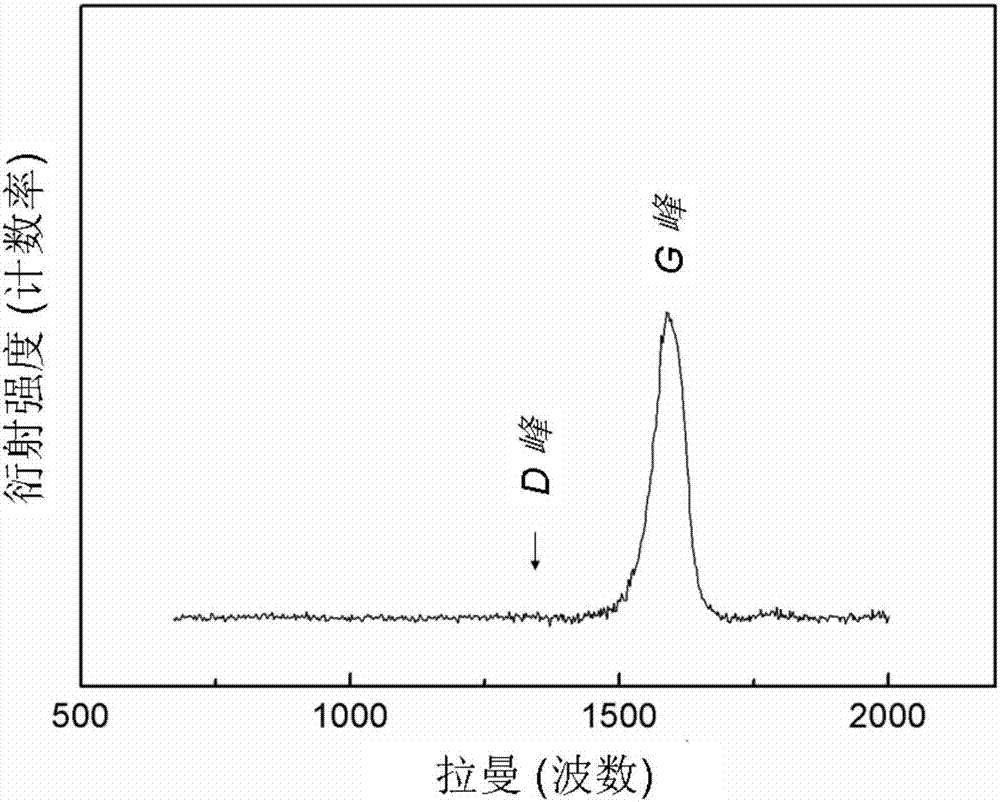

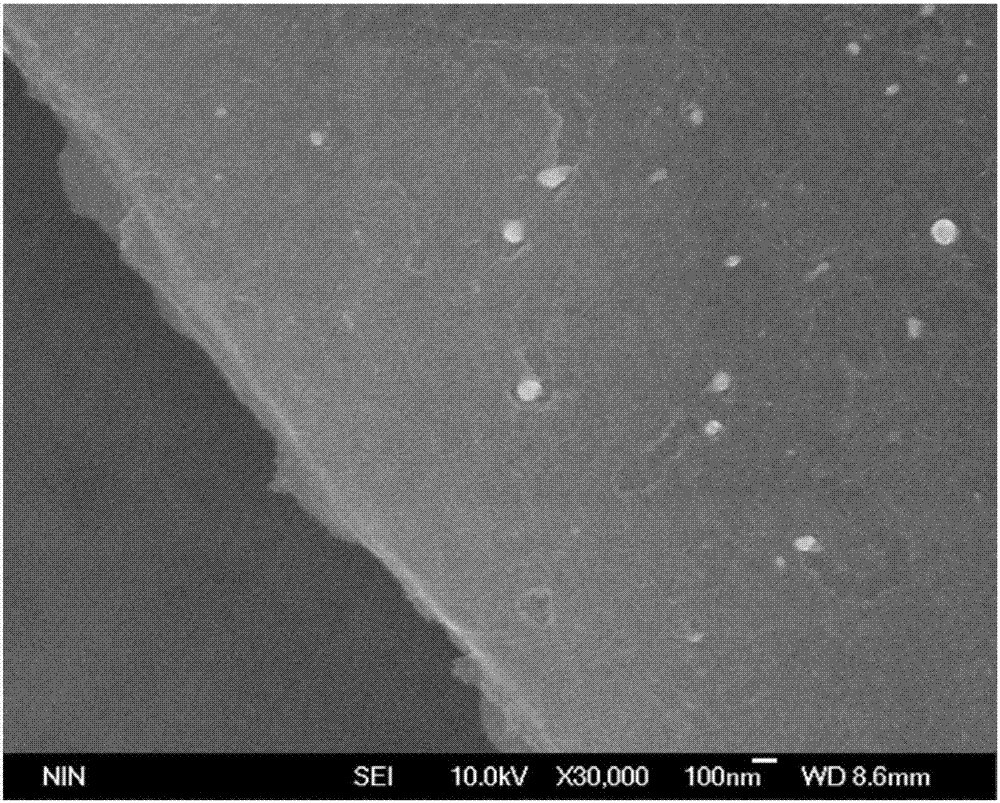

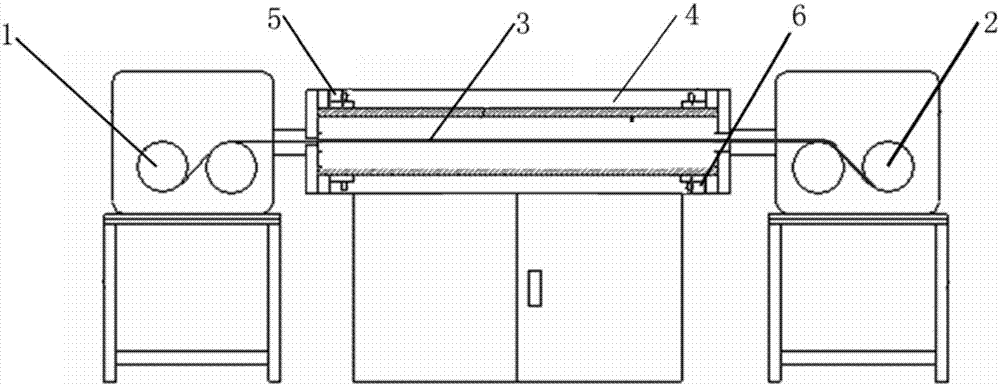

A kind of preparation method of graphene copper composite wire

A composite wire and graphene technology, applied in conductive materials, conductive materials, metal/alloy conductors, etc., can solve the problems of complex atmosphere control and high preparation cost, and achieve the effects of shortening preparation time, simple method and short preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The preparation method of graphene copper composite wire in the present embodiment comprises the following steps:

[0033] Step 1, dissolving graphene oxide as a precursor in a mixed solvent, adding polyvinylpyrrolidone or N-methylpyrrolidone as a stabilizer, and stirring and dissolving under ultrasonic vibration conditions to obtain a precursor solution; the polyvinylpyrrolidone or The amount of N-methylpyrrolidone added is 1% of the mass of graphene oxide; the concentration of graphene oxide in the precursor solution is 2.5 mg / mL; the mixed solvent is mixed with water and ethanol at a volume ratio of 1:10 Made; the power of the ultrasonic oscillation is 550W;

[0034] Step 2, the precursor solution described in step 1 is applied to the copper strip by dipping and pulling method to obtain a copper strip covered with a graphene oxide coating, and then the copper strip coated with a graphene oxide coating is placed on the copper strip The temperature is 135°C, and the d...

Embodiment 2

[0043] The preparation method of graphene copper composite wire in the present embodiment comprises the following steps:

[0044] Step 1, dissolving graphene oxide as a precursor in a mixed solvent, adding polyvinylpyrrolidone or N-methylpyrrolidone as a stabilizer, and stirring and dissolving under ultrasonic vibration conditions to obtain a precursor solution; the polyvinylpyrrolidone or The amount of N-methylpyrrolidone added is 1% of the mass of graphene oxide; the concentration of graphene oxide in the precursor solution is 0.5 mg / mL; the mixed solvent is mixed with water and ethanol at a volume ratio of 1:10 Made; the power of the ultrasonic oscillation is 100W;

[0045] Step 2, the precursor solution described in step 1 is applied to the copper strip by dipping and pulling method to obtain a copper strip covered with a graphene oxide coating, and then the copper strip coated with a graphene oxide coating is placed on the copper strip The drying treatment is carried out...

Embodiment 3

[0054] The preparation method of graphene copper composite wire in the present embodiment comprises the following steps:

[0055] Step 1, dissolving graphene oxide as a precursor in a mixed solvent, adding polyvinylpyrrolidone or N-methylpyrrolidone as a stabilizer, and stirring and dissolving under ultrasonic vibration conditions to obtain a precursor solution; the polyvinylpyrrolidone or The amount of N-methylpyrrolidone added is 1% of the graphene oxide mass; the concentration of graphene oxide in the precursor solution is 5 mg / mL; the mixed solvent is composed of dimethylformamide and ethanol in a volume ratio of 1 : 10 mixed; the power of the ultrasonic oscillation is 1000W;

[0056] Step 2, the precursor solution described in step 1 is applied to the copper strip by dipping and pulling method to obtain a copper strip covered with a graphene oxide coating, and then the copper strip coated with a graphene oxide coating is placed on the copper strip The drying treatment is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com